Fully Automatic Soap Making Machine Price In India

Top sponsor listing

Top sponsor listing

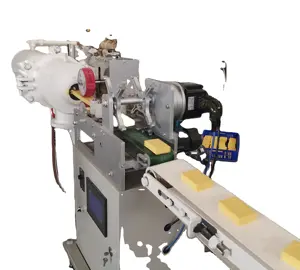

1/10

1/10

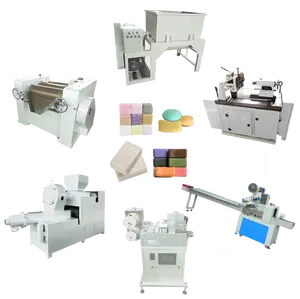

1/30

1/30

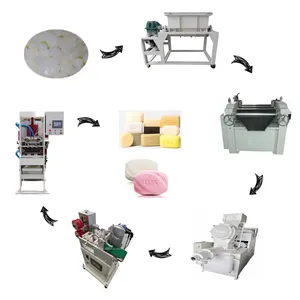

1/33

1/33

1/15

1/15

1/14

1/14

About fully automatic soap making machine price in india

Where to Find Fully Automatic Soap Making Machine Suppliers?

China is the dominant manufacturing hub for fully automatic soap making machines, with key industrial clusters concentrated in Henan Province. This region hosts a high density of machinery manufacturers specializing in chemical processing and packaging equipment, benefiting from integrated supply chains for steel, molds, automation components, and control systems. Zhengzhou, the provincial capital, serves as a major logistics nexus, enabling efficient domestic and international shipping—critical for heavy machinery exports to markets like India.

These clusters support vertically integrated production ecosystems where suppliers manage casting, CNC machining, assembly, and testing under one roof. This integration reduces component lead times by 20–30% compared to fragmented supply models. Buyers gain access to scalable production capacities, with facilities averaging 5,000–25,000+ m² capable of fulfilling bulk orders (1–10+ units monthly). The regional specialization enables competitive pricing, with production cost advantages of 15–25% over non-Asian manufacturers due to lower labor and overhead expenses.

How to Choose Fully Automatic Soap Making Machine Suppliers?

Procurement decisions should be guided by systematic evaluation of technical, operational, and transactional performance indicators:

Technical Compliance and Equipment Specifications

Verify that machines meet baseline automation standards: programmable logic controllers (PLCs), touch-screen HMI interfaces, and integrated cooling, extrusion, stamping, and wrapping functions. For export compliance, confirm CE or ISO certification for electrical and mechanical safety. Request detailed technical drawings, material specifications (e.g., stainless steel grade 304/316), and validation reports for critical subsystems such as hydraulic presses and temperature control units.

Production Capability Assessment

Evaluate supplier infrastructure using these benchmarks:

- Minimum factory area of 3,000m² for dedicated soap machine production lines

- In-house engineering teams supporting customization (e.g., output capacity adjustments from 100kg/h to 1,000kg/h)

- CNC machining, welding, and surface treatment capabilities to ensure build quality

Cross-reference on-time delivery rates (>95% target) and response time (<4 hours) with order volume data to assess operational reliability.

Transaction Risk Mitigation

Utilize secure payment mechanisms such as third-party escrow or letter of credit (LC) terms. Prioritize suppliers with documented quality management systems and after-sales service protocols. Conduct pre-shipment inspections either independently or through trade assurance programs. Sample testing is recommended to validate machine performance against claimed output, energy consumption, and soap bar consistency metrics before full-scale procurement.

What Are the Best Fully Automatic Soap Making Machine Suppliers?

| Company Name | Location | Main Products | On-Time Delivery | Reorder Rate | Avg. Response | Online Revenue | Customization |

|---|---|---|---|---|---|---|---|

| Henan Lovo Industry Co., Ltd. | Henan, CN | Soap Making Machines, Construction Machinery | 95% | 23% | ≤3h | US $540,000+ | Yes (color, size, logo, packaging) |

| Henan Taion Industry Co., Ltd. | Henan, CN | Soap Making Machines, Chemical Equipment | 100% | <15% | ≤1h | US $10,000+ | No explicit mention |

| Zhengzhou Mona Machinery Co., Ltd. | Henan, CN | Meat Processing, Farm Machinery | 100% | 40% | ≤4h | US $80,000+ | No explicit mention |

| KAIFENG JASUN INDUSTRY INC | Henan, CN | Soap Making Machines, Mixing Equipment | - | - | ≤1h | - | No explicit mention |

| Zhengzhou Hento Machinery Co., Ltd. | Zhengzhou, CN | Soap Making Machines, Packaging Systems | 100% | 24% | ≤1h | US $360,000+ | Yes (material, size, labeling) |

Performance Analysis

Henan Taion and Zhengzhou Hento demonstrate strong operational discipline with 100% on-time delivery and sub-1 hour response times, indicating robust customer service infrastructure. Zhengzhou Mona stands out with a 40% reorder rate—the highest among listed suppliers—suggesting high end-user satisfaction despite broader product diversification. Henan Lovo and Zhengzhou Hento offer confirmed customization options for branding and integration, essential for private-label or facility-specific installations. While KAIFENG JASUN offers competitive entry-level pricing ($1,000–$10,000 range), absence of verifiable performance metrics increases procurement risk. Buyers should prioritize suppliers with transparent transaction histories and proven export experience to India, particularly those familiar with voltage (415V/3-phase) and packaging regulatory requirements.

FAQs

What is the typical price range for fully automatic soap making machines in India?

Imported fully automatic soap making machines from Chinese suppliers range from $1,000 for compact models to $75,000 for complete turnkey lines with finishing and packaging. Mid-range industrial units (100–500kg/h output) typically fall between $8,000–$25,000, depending on automation level and auxiliary components.

What are common MOQ and lead times?

Minimum order quantity is generally 1 set, allowing for sample procurement. Standard lead times range from 20–40 days post-deposit, depending on customization complexity. Express production may reduce timelines by 7–10 days at additional cost.

Can suppliers customize machines for Indian market requirements?

Yes, select suppliers offer voltage adaptation (to 415V/3-phase), localized control panel labeling, and integration with existing plant layouts. Customization extends to mold design (brand logos), output capacity tuning, and material contact compliance (food-grade stainless steel).

Do suppliers provide installation and training support?

Support varies by supplier. Some include remote guidance via video, while others offer on-site commissioning services at additional cost. Technical manuals, wiring diagrams, and preventive maintenance schedules are typically provided with shipment.

How to verify machine performance before purchase?

Request live video demonstrations or factory test runs. Obtain sample soap bars produced on the machine to evaluate dimensional accuracy, density, and surface finish. Review PLC interface functionality and alarm logging features to assess operational usability.