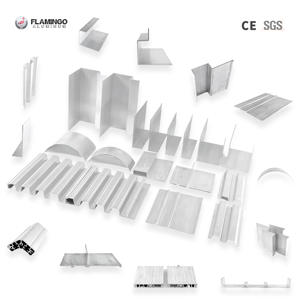

Material Extrusion Examples

Top sponsor listing

Top sponsor listing

1/20

1/20

1/19

1/19

1/25

1/25

1/21

1/21

1/19

1/19

1/29

1/29

1/9

1/9

1/36

1/36

About material extrusion examples

Where to Find Material Extrusion Examples Suppliers?

China leads global production of material extrusion solutions, with key manufacturing clusters in Shanghai, Xiamen, and Suzhou offering specialized capabilities in aluminum profile fabrication. These regions host vertically integrated suppliers combining extrusion lines, CNC machining centers, and surface treatment facilities within single campuses. Shanghai and Suzhou are recognized for precision engineering ecosystems, supporting tight-tolerance profiles (±0.1mm) used in industrial automation and thermal management systems. Xiamen’s export-oriented manufacturers focus on cost-competitive custom extrusions, leveraging regional aluminum supply chains to reduce raw material costs by 15–20% compared to Western counterparts.

The concentration of technical expertise and ancillary services—including anodizing, powder coating, and laser cutting—enables rapid prototyping and scalable production. Buyers benefit from lead times averaging 20–35 days for custom orders, with access to full-service providers capable of design validation, tooling fabrication, and kitted packaging. The ecosystem supports both high-volume OEM contracts and low-MOQ sampling, making it ideal for product development and serial production.

How to Choose Material Extrusion Examples Suppliers?

Implement the following evaluation criteria when selecting extrusion partners:

Technical Compliance & Quality Systems

Confirm adherence to ISO 9001 or equivalent quality management standards. For applications requiring corrosion resistance or electrical insulation, verify process controls for anodizing thickness (typically 8–25μm) and dielectric performance. Suppliers serving EU markets should demonstrate compliance with RoHS directives for surface treatments.

Production Capability Assessment

Evaluate core infrastructure metrics:

- Minimum 3,000m² factory area for stable extrusion line operation

- In-house tooling and CNC machining capacity for post-processing

- Monthly extrusion output exceeding 200 metric tons

Cross-reference on-time delivery rates (target ≥97%) and response times (≤2 hours) as indicators of operational efficiency.

Customization & Transaction Security

Prioritize suppliers offering end-to-end customization—from alloy selection (6061, 6063, 7075) to finish options (brushed, matte, wood grain)—with documented design support workflows. Utilize secure transaction platforms where available, ensuring payment protection until shipment verification. Request physical or digital samples to validate dimensional accuracy, surface finish consistency, and structural integrity prior to bulk ordering.

What Are the Best Material Extrusion Examples Suppliers?

| Company Name | Location | Verified Type | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Customization Options | Main Products |

|---|---|---|---|---|---|---|---|---|

| Zhangjiagang Channel Int'l Co., Ltd. | Jiangsu, CN | Multispecialty Supplier | 89% | ≤2h | <15% | US $650,000+ | Engraving, anodizing, threading, slotting, magnetization, coil forming, graphic labeling | Aluminum Profiles, T-Slot Systems, Decorative Extrusions |

| Xiamen Hongxing Import & Export Co., Ltd. | Xiamen, CN | Multispecialty Supplier | 100% | ≤2h | 34% | US $120,000+ | Color, length, thickness, hole diameter, logo, packaging | Custom Aluminum Frames, Glass Door Profiles, Whiteboard Extrusions |

| Suzhou HoGreat Metal Product Co., Ltd. | Suzhou, CN | - | 100% | ≤1h | - | - | Profile geometry, size, finish, length | Industrial Equipment Extrusions, Radiator Profiles, Machined Components |

| Shanghai Common Metal Products Co., Ltd. | Shanghai, CN | Custom Manufacturer | 97% | ≤2h | 28% | US $190,000+ | Color, thickness, anodizing, precision dimensions, labeling, hole patterns | Aluminum Profiles, Brackets, Fasteners, Door & Window Hardware |

| Shanghai Matech Machinery Manufacture Corporation Ltd. | Shanghai, CN | - | 100% | ≤1h | <15% | US $20,000+ | Hexagonal internal extrusions, t-slot configurations, precision tolerances | 40-Series T-Slot Profiles, Square Tubes, Machinery Shafts |

Performance Analysis

Xiamen Hongxing and Suzhou HoGreat lead in reliability with 100% on-time delivery and sub-2-hour response times, indicating strong operational discipline. Zhangjiagang Channel stands out for extensive customization depth, supporting complex functional features like magnetic integration and shock cord channels. Shanghai-based suppliers offer broad application coverage—from architectural frames to industrial automation components—with moderate reorder rates suggesting room for service improvement. Buyers seeking high-repeatability profiles should prioritize partners with documented CNC finishing and in-house metrology equipment. For fast-turnaround sampling, target suppliers advertising ≤1-hour response times and low MOQs (as low as 1 piece or 1kg).

FAQs

How to verify material extrusion supplier reliability?

Validate certifications through issuing bodies and request process documentation for critical stages such as billet heating, press calibration, and aging cycles. Review customer feedback focused on dimensional consistency, coating adhesion, and packaging integrity. Conduct virtual audits to observe facility conditions and workflow organization.

What is the typical minimum order quantity (MOQ)?

MOQ varies by supplier and pricing model: some offer 1-piece sampling for frame prototypes, while others require 100kg or 100-piece minimums for cost-effective production runs. Bulk pricing typically applies at 500kg+ volumes.

What materials are commonly used in extrusion examples?

6063-T5 aluminum dominates for general-purpose profiles due to excellent formability and surface finish. 6061-T6 is preferred for structural applications requiring higher strength. Specialty alloys like 7075 are used in aerospace-grade components, while recycled aluminum streams support sustainable sourcing initiatives.

Can suppliers provide free samples?

Sample policies differ: some suppliers waive fees for qualified buyers committing to future volume orders. Others charge nominal fees covering material and handling, which may be credited toward first production orders. Expect 7–15 days for sample fabrication and international shipping.

How long does customization take?

Dies for new profiles typically require 10–20 days to fabricate. Prototype extrusions follow within 3–5 days after die completion. Full production lead time ranges from 20–35 days depending on order complexity, finishing requirements, and logistics planning.