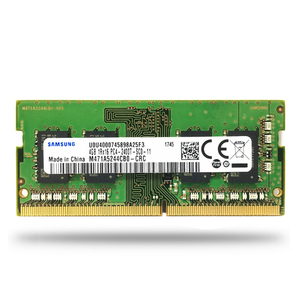

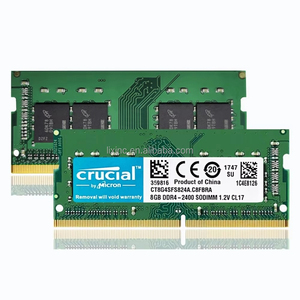

Memory Ram Ddr4 Laptop

Top sponsor listing

Top sponsor listing

1/3

1/3

CN

CN

1/3

1/3

0

0

1/3

1/3

1/1

1/1

1/3

1/3

1/1

1/1

1/2

1/2

1/8

1/8

0

0

0

0

1/3

1/3

1/3

1/3

1/2

1/2

1/2

1/2

0

0

0

0

1/3

1/3

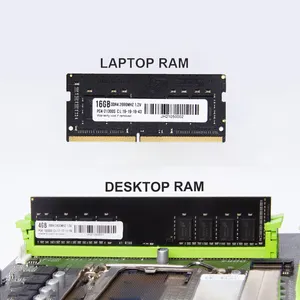

About memory ram ddr4 laptop

Where to Find Memory RAM DDR4 Laptop Suppliers?

China remains the central hub for memory module manufacturing, with key production clusters in Guangdong, Jiangsu, and Shanghai driving global supply. These regions host vertically integrated facilities capable of assembling DDR4 SODIMMs using imported DRAM chips from Samsung, SK Hynix, and Micron, combined with locally produced PCBs and connectors. Guangdong’s Dongguan and Shenzhen zones account for over 50% of China’s consumer-grade RAM output, supported by mature electronics ecosystems offering rapid component sourcing and testing infrastructure.

Manufacturers in these clusters benefit from proximity to semiconductor packaging and testing services, reducing turnaround times for small to mid-volume orders. Production lines are typically optimized for automated surface-mount technology (SMT), enabling consistent assembly of 8GB, 16GB, and 32GB DDR4 modules at speeds of up to 5,000 units per day per line. Buyers gain access to scalable capacity, with lead times averaging 15–25 days for MOQs between 100–500 units. Localized logistics networks further support air or sea consolidation for global shipment, particularly via Hong Kong and Shanghai ports.

How to Choose Memory RAM DDR4 Laptop Suppliers?

Implement structured evaluation criteria to mitigate quality and compliance risks:

Technical Compliance

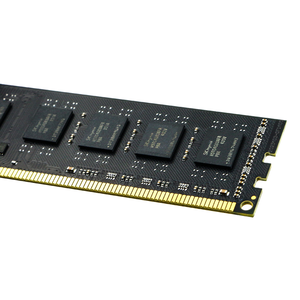

Confirm adherence to JEDEC DDR4 SDRAM standards for voltage (1.2V), clock speeds (2133MHz–3200MHz), and signal integrity. Suppliers should provide test reports verifying timing parameters, thermal performance, and compatibility with mainstream laptop platforms (e.g., Intel 10th–12th Gen, AMD Ryzen 4000/5000 series). For EU and North American markets, ensure RoHS and REACH compliance documentation is available to clear customs and meet environmental regulations.

Production Capability Audits

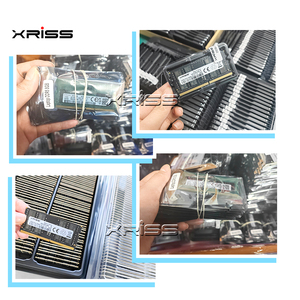

Assess operational scale and process control through the following indicators:

- Minimum 2,000m² cleanroom facility with ESD-protected SMT lines

- In-house testing bays equipped with burn-in racks and memory analyzers

- Use of lead-free reflow soldering and AOI (Automated Optical Inspection) for defect detection

Cross-reference factory size and equipment lists with order fulfillment history, targeting suppliers maintaining >95% on-time delivery rates.

Transaction Safeguards

Utilize secure payment methods such as irrevocable LC or third-party escrow, releasing funds only after sample validation. Request pre-shipment inspection reports covering functional testing, labeling accuracy, and packaging integrity. Prioritize suppliers with documented QC processes—ideally ISO 9001-certified—and a track record of exporting to Tier-1 distributors or OEMs.

What Are the Best Memory RAM DDR4 Laptop Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|

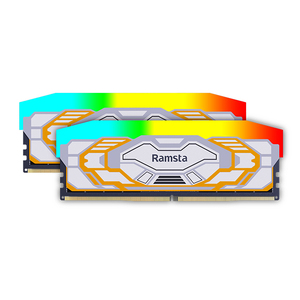

Performance Analysis

Without specific supplier data, procurement focus should remain on operational transparency and technical verification. In established clusters, long-standing manufacturers often demonstrate higher reorder rates due to consistent yield performance and responsive technical support. Newer entrants may offer competitive pricing but require stricter validation of material traceability and testing protocols. Prioritize partners with documented experience in laptop SODIMM assembly, particularly those supporting dual-channel configurations, XMP profiles, and heat-spreader integration. Video audits of SMT and burn-in testing stages are recommended to confirm process rigor before volume ordering.

FAQs

How to verify memory RAM DDR4 laptop supplier reliability?

Validate certifications (ISO 9001, RoHS) through official databases and request batch-specific test reports for recent production runs. Conduct remote audits via live video tours focusing on SMT line calibration, ESD controls, and final functional testing procedures. Analyze customer feedback for recurring issues related to stability, overclocking failure, or BIOS incompatibility.

What is the average sampling timeline?

Standard sample production takes 7–14 days, including PCB population, programming, and 48-hour burn-in testing. Custom variants with heat spreaders or serialized labeling extend to 20 days. Air freight adds 5–8 days for international delivery, depending on destination region.

Can suppliers ship memory modules worldwide?

Yes, most manufacturers support global shipping via express courier (DHL, FedEx) for samples and consolidated LCL/air freight for bulk orders. Confirm Incoterms (FOB Shenzhen, CIF Rotterdam, etc.) and ensure export packaging meets ESD-safe standards with moisture barrier bags and rigid outer cartons.

Do manufacturers provide free samples?

Sample policies vary: established suppliers may offer one free sample per buyer for qualified leads, while others charge a fee covering material and labor (typically $20–$50), refundable against first purchase. Free samples are rarely offered without verified business registration or purchase intent.

How to initiate customization requests?

Submit detailed specifications including capacity (8GB/16GB), speed grade (PC4-2133 to PC4-3200), voltage tolerance, and physical requirements (heat spreader color, label design). Reputable suppliers will return confirmation drawings within 48 hours and deliver prototypes within 10–14 days for approval.