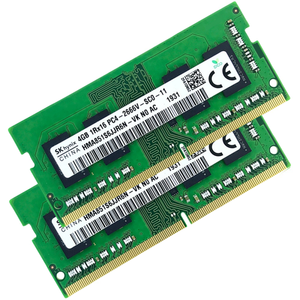

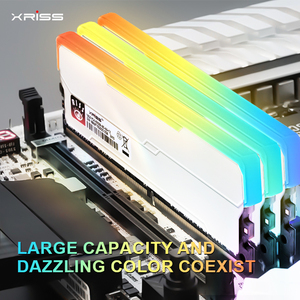

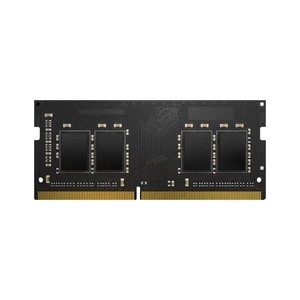

Ram Notebook Ddr4

Top sponsor listing

Top sponsor listing

1/2

1/2

1/1

1/1

1/3

1/3

1/13

1/13

1/6

1/6

1/11

1/11

1/1

1/1

1/2

1/2

1/3

1/3

1/3

1/3

1/31

1/31

1/3

1/3

0

0

1/4

1/4

0

0

1/25

1/25

0

0

1/3

1/3

About ram notebook ddr4

Where to Find RAM Notebook DDR4 Suppliers?

China remains the central hub for memory module manufacturing, with key production clusters in Guangdong and Jiangsu provinces driving global supply. Guangdong’s Shenzhen region hosts a dense network of electronics component manufacturers, benefiting from proximity to semiconductor packaging facilities and IC testing centers. This integration enables streamlined production of DDR4 SODIMMs used in notebooks, reducing material transit time by up to 40% compared to dispersed supply chains. Jiangsu’s Suzhou industrial zone specializes in high-frequency memory modules, leveraging cleanroom assembly lines and automated optical inspection (AOI) systems to maintain signal integrity and thermal stability.

These regions support vertical integration across PCB fabrication, surface-mount technology (SMT), and final testing, allowing suppliers to scale output rapidly. Buyers gain access to ecosystems where DRAM ICs, PCB substrates, and passive components are sourced within 30km, minimizing logistics delays. Key advantages include lead times averaging 25–35 days for bulk orders, cost efficiencies of 18–25% due to localized sourcing, and flexibility for custom timing profiles or heat spreader designs. Most facilities operate under ISO 14644-1 Class 7 or better cleanroom standards, ensuring consistent yield rates above 98.5%.

How to Choose RAM Notebook DDR4 Suppliers?

Implement structured evaluation criteria to ensure technical and operational reliability:

Quality & Compliance Verification

Confirm adherence to JEDEC DDR4 specifications as baseline performance validation. For international markets, verify compliance with RoHS and REACH directives to meet environmental regulations. Request test reports from third-party labs covering signal integrity, temperature cycling (-20°C to +85°C), and endurance (1,000+ write cycles). ISO 9001 certification should be mandatory, with ISO 14001 and IATF 16949 preferred for automotive-grade or industrial applications.

Production Infrastructure Assessment

Evaluate core capabilities through documented evidence:

- Minimum 3,000m² factory area with dedicated SMT and testing zones

- SMT lines equipped with SPI (solder paste inspection) and AOI systems

- In-house testing using BGA rework stations and memory analyzers

Cross-reference facility size with monthly output capacity (target ≥500,000 modules) and on-time delivery performance (benchmark >97%) to validate scalability.

Procurement Risk Mitigation

Utilize escrow-based transaction models until product verification is complete. Review supplier export history, particularly shipments to North America and EU regions, to confirm customs clearance proficiency. Pre-shipment sampling is critical—conduct functional tests on sample batches using standard notebook platforms to validate compatibility, clock speed, and power draw under load.

What Are the Best RAM Notebook DDR4 Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Supplier data currently unavailable for analysis | ||||||||

Performance Analysis

While specific supplier data is not available in this dataset, market benchmarks indicate that established manufacturers typically offer higher reorder rates (>30%) and faster response times (≤2 hours) due to dedicated customer engineering teams. Long-operating entities often exceed 10,000m² in facility size, supporting automated SMT lines capable of producing over 1 million DDR4 SODIMMs per month. Prioritize suppliers with documented JEDEC compliance, verified testing protocols, and experience exporting to regulated markets. For customized configurations—such as low-latency CL14 modules or industrial-temperature variants—require proof of in-house design validation before order placement.

FAQs

How to verify RAM notebook DDR4 supplier reliability?

Validate certifications through issuing bodies and request audit trails covering incoming IC inspection, soldering profiles, and burn-in testing. Analyze customer feedback focusing on module compatibility, defect rates, and technical support responsiveness. On-site or virtual factory audits can confirm automation levels and quality control checkpoints.

What is the average sampling timeline?

Standard sample production takes 10–18 days, including programming of SPD EEPROMs and functional validation. For custom voltage or timing configurations, allow 22–30 days. Air freight adds 5–9 days depending on destination.

Can suppliers ship globally?

Yes, most manufacturers support international shipping via air or sea freight. Confirm Incoterms (FOB Shenzhen, CIF Rotterdam, etc.) and ensure compliance with import regulations regarding electronic components. ESD-safe packaging and moisture barrier bags are standard for all shipments.

Do manufacturers provide free samples?

Sample policies vary. Established suppliers may waive fees for qualified buyers with projected annual volumes exceeding 10,000 units. Otherwise, expect to cover material and handling costs, typically ranging from $50–$150 per sample kit.

How to initiate customization requests?

Submit detailed specifications including capacity (8GB–32GB), speed (2400MT/s–3200MT/s), voltage (1.2V standard), and form factor (260-pin SODIMM). Reputable partners will provide SPD data sheets, layout recommendations, and prototype timelines within 72 hours of inquiry.