Mesh Led Display Producer

1/3

1/3

1/3

1/3

1/18

1/18

0

0

1/24

1/24

1/3

1/3

1/16

1/16

1/11

1/11

1/26

1/26

1/3

1/3

1/3

1/3

1/25

1/25

1/18

1/18

1/34

1/34

CN

CN

1/33

1/33

1/2

1/2

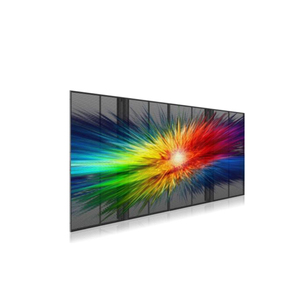

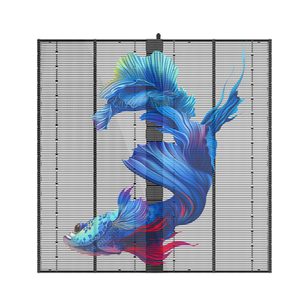

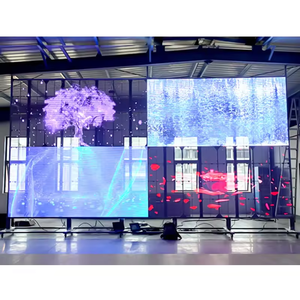

About mesh led display producer

Where to Find Mesh LED Display Producers?

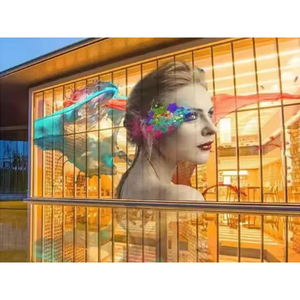

China remains the global epicenter for mesh LED display manufacturing, with key industrial clusters concentrated in Guangdong and Jiangsu provinces. Guangdong, particularly the Pearl River Delta region, hosts over 70% of China’s LED display producers, supported by Shenzhen’s advanced electronics supply chain and export infrastructure. This cluster offers rapid access to critical components such as SMD LEDs, driver ICs, and aluminum cabinets, reducing material procurement cycles by up to 40%. Jiangsu’s Yangtze River Delta corridor specializes in high-transparency mesh displays for architectural façades, leveraging proximity to flat-panel processing facilities and tempered glass suppliers.

These regions enable vertically integrated production models—from PCB assembly and cabinet fabrication to final system integration—within tightly coordinated industrial zones. Suppliers benefit from localized ecosystems where raw materials, surface-mount technology (SMT) lines, and logistics providers operate within 30km radii. Buyers gain advantages including lead times of 25–40 days for standard orders, 15–25% lower unit costs due to economies of scale, and flexibility for custom pixel pitch (P3.9 to P10) and module size configurations. Export-ready certifications are commonly embedded in production workflows, facilitating compliance with international electrical safety and EMC standards.

How to Choose Mesh LED Display Producers?

Adopt structured evaluation criteria when assessing potential suppliers:

Quality & Compliance Verification

Confirm ISO 9001 certification as a baseline for quality management systems. For shipments to Europe or North America, validate CE (EN 62368-1, EN 55032) and RoHS compliance documentation. Request test reports for ingress protection (IP65 minimum for outdoor units), luminance uniformity (≥97%), and mean time between failures (MTBF ≥100,000 hours).

Production Infrastructure Assessment

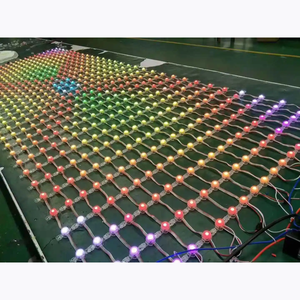

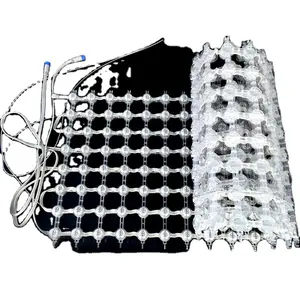

Evaluate core manufacturing capabilities:

- Minimum 3,000m² factory area with climate-controlled SMT and aging rooms

- In-house PCB design and metal fabrication (laser cutting, CNC bending)

- Automated assembly lines with reflow soldering and AOI (Automated Optical Inspection)

Cross-reference facility scale with monthly output capacity (target ≥5,000 sqm) and on-time delivery performance (benchmark >97%).

Procurement Risk Mitigation

Implement transaction safeguards such as third-party inspection upon completion and escrow-based payment terms. Review supplier track records for export experience—particularly FOB Shenzhen or Ningbo shipments—to assess logistical reliability. Conduct sample testing to evaluate grayscale performance, color temperature consistency (±200K tolerance), and structural rigidity under simulated wind loads (≥2 kPa).

What Are the Best Mesh LED Display Producers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Supplier data not available | ||||||||

Performance Analysis

In the absence of specific supplier data, sourcing strategies should emphasize operational transparency and technical validation. Prioritize manufacturers with documented R&D departments (minimum 8% engineering staffing ratio) and investment in thermal management systems for sustained outdoor operation. Proven exporters typically maintain reorder rates above 30%, indicating customer satisfaction with product reliability and after-sales support. For large-scale facade projects, verify prior installations through site visitation or video audits of completed deployments. Focus on suppliers offering modular designs with front-access serviceability and compatibility with standard mounting frameworks.

FAQs

How to verify mesh LED display producer reliability?

Validate certifications through official databases and request audit trails for raw material sourcing (e.g., NationStar/Chipone LEDs). Conduct remote factory assessments via live video tours focusing on SMT line operations, aging procedures, and packaging standards. Analyze client references for project-specific performance in extreme climates or high-humidity environments.

What is the typical sampling timeline?

Standard samples require 12–18 days for production, including PCB assembly, module integration, and 72-hour burn-in testing. Custom configurations involving non-standard cabinet dimensions or wireless control systems may extend to 25–30 days. Air freight delivery adds 5–9 days depending on destination region.

Can mesh LED display producers ship globally?

Yes, experienced manufacturers support worldwide distribution via FOB, CIF, or DDP terms. Confirm adherence to IEC 62368-1 for electrical safety and compliance with local customs codes for LED video walls. Sea freight is optimal for bulk orders exceeding 20 sqm, while air shipping suits urgent sample or replacement module deliveries.

Do manufacturers provide free samples?

Sample policies vary by order volume. Full-size panels are rarely offered free; however, suppliers may offset sample costs (typically 30–60% of unit price) against subsequent bulk orders exceeding 50 sqm. Mini-modules or demo strips are sometimes provided at reduced cost for initial evaluation.

How to initiate customization requests?

Submit detailed technical requirements including desired transparency ratio (≥60%), pixel pitch, cabinet material (aluminum alloy vs. steel), input signal type (HDMI/DVI/SDI), and control system compatibility (Novastar, Linsn). Reputable producers respond with mechanical drawings and control architecture diagrams within 48–72 hours, followed by prototype availability in 3–5 weeks.