Mesh Screen Producer

Top sponsor listing

Top sponsor listing

1/3

1/3

1/3

1/3

0

0

1/3

1/3

1/3

1/3

1/3

1/3

0

0

1/2

1/2

1/3

1/3

0

0

0

0

1/3

1/3

1/2

1/2

1/3

1/3

1/3

1/3

0

0

1/3

1/3

About mesh screen producer

Where to Find Mesh Screen Producers?

China remains the global epicenter for mesh screen manufacturing, with key production clusters concentrated in Hebei and Shandong provinces. These regions host vertically integrated facilities specializing in wire mesh, polyurethane, rubber, and perforated metal screens used across mining, filtration, agriculture, and construction industries. Anping County in Hebei alone accounts for over 70% of China’s wire mesh output, supported by a mature supply chain encompassing steel drawing, weaving, coating, and automated fabrication.

Suppliers in these hubs operate proprietary production lines enabling end-to-end control—from raw material processing to final assembly—reducing lead times and ensuring consistency. The proximity of component suppliers and metallurgical service providers within 30–50 km allows rapid prototyping and scalable batch production. Buyers benefit from competitive pricing (20–35% below Western equivalents), flexible MOQs, and customization capabilities in mesh size, material grade, panel dimensions, and automation integration.

How to Choose Mesh Screen Producers?

Effective supplier selection requires structured evaluation across technical, operational, and transactional criteria:

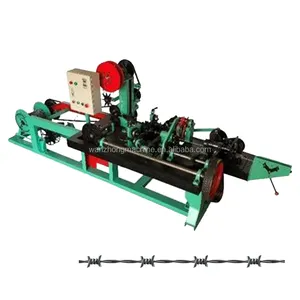

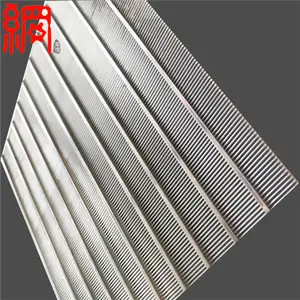

Production & Engineering Capability

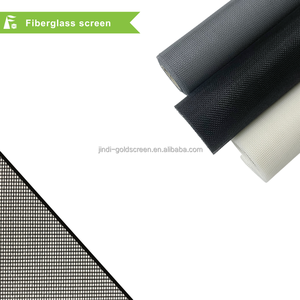

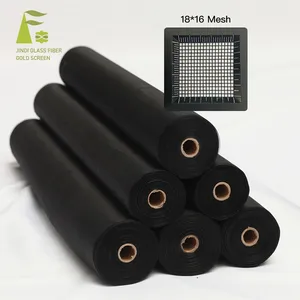

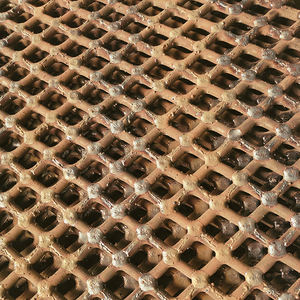

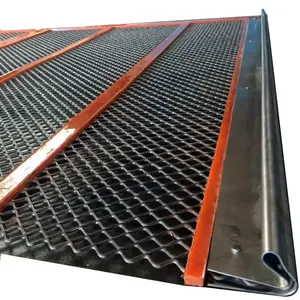

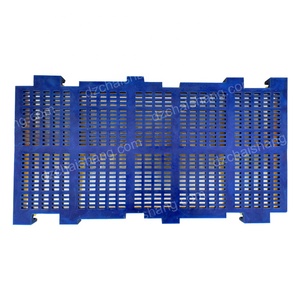

Verify that suppliers maintain in-house production lines for core processes such as wire drawing, crimping, welding, molding, or perforation. Prioritize manufacturers offering customization in wire diameter (ranging from 0.1 mm to 6 mm), mesh count (up to 635 mesh), panel size, and material types—including stainless steel (304/316), galvanized iron, PVC-coated wire, polyurethane, and rubber composites.

- Look for integration of PLC-controlled systems, servo motors, and automatic cutting/unloading mechanisms in machine-based production

- Assess flexibility in roll length, working speed adjustment, lubrication capacity, and motor integration for OEM equipment needs

- Demand evidence of R&D capability, especially for wear-resistant, corrosion-resistant, or high-frequency dewatering applications

Quality Assurance & Compliance

Confirm adherence to international quality standards. While formal ISO 9001 certification is not explicitly listed in available data, consistent on-time delivery rates (100% across all five profiled suppliers) suggest robust internal quality management. For critical applications in food processing or chemical filtration, request documentation on material traceability, tensile strength testing, and compliance with RoHS or FDA regulations where applicable.

Transaction Reliability Metrics

Analyze performance indicators derived from verified transaction histories:

- On-time delivery rate: All five suppliers report 100%, indicating strong logistics coordination

- Reorder rates vary from <15% to 50%, reflecting differences in customer retention and product satisfaction

- Average response time ranges from ≤1h to ≤5h—prioritize those under ≤2h for time-sensitive procurement cycles

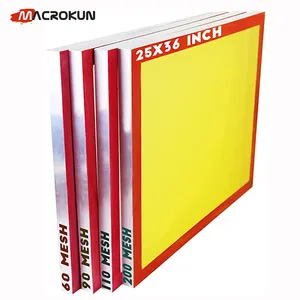

What Are the Best Mesh Screen Producers?

| Company Name | Main Products | Customization Options | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Min. Order Flexibility |

|---|---|---|---|---|---|---|---|

| Anping Wanzhong Wire Mesh Products Co., Ltd. | Wire Mesh Making Machines, Iron Wire Mesh, Nail Making Machines | Mesh size, color, wire diameter, motor integration, automation level, panel dimensions, budget-based design | US $460,000+ | 100% | ≤2h | 42% | Roll length, mesh width, adjustable spacing, automatic unloading |

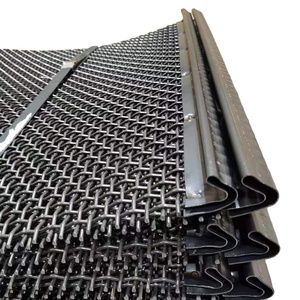

| Hebei Dizhuo Rubber And Plastic Products Co., Ltd. | Polyurethane Screen Panels, Vibrating Screen Parts, Rubber Rollers | OEM/ODM support, custom sizes, dewatering configurations, linear ore separation designs | US $40,000+ | 100% | ≤3h | 50% | Single-piece orders accepted |

| Binzhou Fangze Screen Mesh Co., Ltd. | Welded Mesh Screens, Perforated Stainless Steel, Sand Washer Mesh | Hole shape, material grade, corrosion resistance, wear resistance, custom dimensions | US $10,000+ | 100% | ≤2h | 50% | As low as 1 square meter (perforated steel) |

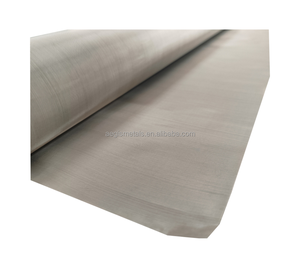

| Anping County Hecheng Metal Products Co., Ltd. | Filter Meshes, 304/316 Stainless Steel Mesh, High-Precision Weave | Micron-level precision, custom mesh counts up to 635, alloy-specific fabrication | US $3,000+ | 100% | ≤1h | 33% | 10–100 pieces depending on spec |

| Hengshui Dingyuan Engineering Rubber&plastic Co., Ltd. | Rubber Vibrating Screen Panels, Curved Mesh Inserts, Mining Liners | Shape, durometer, thickness, mounting configuration, application-specific formulations | US $100+ | 100% | ≤5h | <15% | Single-piece orders standard |

Performance Analysis

Anping Wanzhong leads in revenue scale and engineering breadth, offering full machine integration for automated mesh production. Hebei Dizhuo and Binzhou Fangze stand out with 50% reorder rates, suggesting high client satisfaction in polyurethane and welded mesh segments. Anping County Hecheng excels in responsiveness (≤1h) and precision metal weaving, ideal for fine-filter applications. Hengshui Dingyuan, while less active online, provides niche rubber solutions for heavy-duty mining screens at accessible price points ($15–25/unit).

FAQs

What materials are commonly used by mesh screen producers?

Stainless steel (304, 316), low-carbon steel, galvanized iron, PVC-coated wire, polyurethane, and natural/synthetic rubber are standard. Material choice depends on application requirements for corrosion resistance, tensile strength, abrasion tolerance, and chemical exposure.

What is the typical MOQ for mesh screen orders?

MOQ varies by type: perforated metal sheets can be ordered from 1 m², welded wire mesh from 10–30 m², rubber/polyurethane panels from 1 piece, and precision filter mesh from 10–100 units. High-volume buyers often negotiate bulk pricing starting at 500+ units.

How long does it take to receive samples?

Standard sample lead time is 7–14 days for stock configurations. Custom designs requiring tooling or formulation adjustments may require 15–25 days. Air shipping adds 5–10 days internationally.

Can mesh screen producers integrate automation features?

Yes, advanced manufacturers like Anping Wanzhong offer PLC integration, servo-driven straightening systems, automatic cutting, and tri-phase motor compatibility for seamless integration into industrial lines.

Are free samples available?

Some suppliers provide paid samples refundable against future orders. Fully free samples are rare but possible for high-potential buyers. Expect to pay 30–70% of unit cost for sampling, especially for engineered polymers or precision metal meshes.