Mesh Making Machine Producer

CN

CN

CN

CN

CN

CN

About mesh making machine producer

Where to Find Mesh Making Machine Producers?

China remains the dominant global hub for mesh making machine manufacturing, with key industrial clusters concentrated in Hebei and Anping—renowned for specialized wire mesh machinery production. These regions host vertically integrated supply chains, combining raw material processing, precision engineering, and final assembly under one ecosystem. The proximity of steel suppliers, CNC fabrication units, and logistics networks enables cost reductions of 20–30% compared to non-specialized regions.

Manufacturers in Anping and surrounding areas benefit from decades of accumulated technical expertise in wire deformation, crimping, weaving, and automation systems. Facilities typically operate on scales ranging from 1,000 to over 20,000 m², supporting both standard model output and custom configurations. Average lead times for standard machines range from 25–40 days, with established players offering faster turnaround due to pre-stocked components and modular design approaches. This regional concentration ensures access to skilled labor pools and rapid prototyping capabilities, enhancing responsiveness for international buyers.

How to Choose Mesh Making Machine Producers?

Selecting reliable producers requires a structured evaluation across technical, operational, and transactional dimensions:

Technical & Production Capability

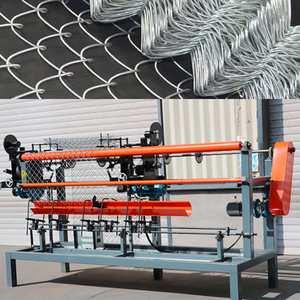

Assess core competencies in machine types: chain link, crimped, welded, hexagonal (gabion), and diamond mesh systems. Verify whether the supplier maintains in-house R&D and engineering teams capable of customization—including wire diameter range (typically 1.5–6mm), mesh size adjustability, and integration of PLC controls or servo motors. Prioritize manufacturers with documented automation levels (semi-automatic to fully automatic) and confirmed production capacity exceeding 30 units per month.

Quality Assurance and Compliance

While formal ISO 9001 certification is not universally listed, evaluate alternative quality indicators such as on-time delivery performance (target ≥95%), response time (ideally ≤2 hours), and presence of online revenue verification. For export compliance, CE marking is critical for European markets, though its explicit mention varies among suppliers. Request test reports on motor efficiency, structural durability, and safety interlocks before shipment.

Customization and Engineering Support

Leading producers offer configurable options including:

- Mesh hole size and pattern geometry

- Wire diameter compatibility (stainless steel, galvanized iron, monofilament)

- Production speed settings and roll length control

- Integration of automatic cutting, straightening, and unloading systems

- PLC/HMI interface programming and energy-efficient drive systems

Confirm availability of technical drawings, 3D renderings, and pre-shipment video inspections to validate design alignment.

Transaction Risk Mitigation

Utilize secure payment mechanisms such as escrow services where possible. Analyze reorder rates as an indicator of customer satisfaction—suppliers with rates above 40% demonstrate consistent post-sale performance. Conduct factory audits via video tour to verify equipment condition, workforce activity, and inventory management practices. Sample testing is recommended to benchmark welding consistency, tension control, and long-term operational stability.

What Are the Top Mesh Making Machine Producers?

| Company Name | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Specialization |

|---|---|---|---|---|---|---|---|---|

| Hebei Houhong Metal Wire Mesh Products Co., Ltd. | Chain Link, Crimped Mesh Machines | $1,200–3,000 | 1 set | 100% | ≤2h | - | - | Entry-level automated systems |

| Anping Shunwei Wiremesh Machinery Manufacturing Co., Ltd. | Fully Automatic Chain Link, Double Wire Mesh | $3,200–15,000 | 1 set | 100% | ≤8h | <15% | - | High-tension diamond and barbed wire systems |

| Hebei Zhongheng Wire Mesh Produce Co., Ltd. | Gabion, Hexagonal, Stainless Steel Woven Mesh | $4,600–26,800 | 1 set | 100% | ≤8h | <15% | US $200+ | Heavy-duty industrial and civil engineering applications |

| Hebei Oulite Import & Export Trading Co., Ltd. | Welded Mesh, Full-Automatic Roll Forming | $5,000–17,200 | 1 set | 50% | ≤10h | <15% | US $80,000+ | Broad customization in mesh width, hole size, and material handling |

| Anping Wanzhong Wire Mesh Products Co., Ltd. | Fully Automatic Diamond, PVC-Coated Mesh Machines | $4,650–19,500 | 1 set | 100% | ≤1h | 42% | US $460,000+ | Advanced automation with servo control and PLC integration |

Performance Analysis

Anping Wanzhong stands out with the highest verified online revenue and a 42% reorder rate, indicating strong market trust and after-sales reliability. Its sub-one-hour average response time reflects optimized communication protocols suitable for urgent procurement cycles. Hebei Houhong offers the most competitive entry-level pricing, ideal for small-scale operations or startups. In contrast, Hebei Zhongheng and Anping Shunwei focus on high-end applications such as gabion baskets and double-wire fencing, commanding premium price points supported by robust build quality. Notably, Hebei Oulite exhibits lower on-time delivery performance (50%), suggesting potential fulfillment risks despite significant transaction volume. Buyers should prioritize suppliers with 100% on-time delivery records and proven experience in exporting to regulated markets.

FAQs

How to verify mesh making machine producer reliability?

Cross-check claimed production capabilities with available product specifications and request facility videos or live inspection sessions. Evaluate responsiveness, order history, and customer feedback patterns. Prioritize partners with consistent delivery performance and clear documentation of component sourcing and quality checks.

What is the typical MOQ and lead time?

Minimum order quantity is typically 1 set, enabling low-risk sampling. Lead times average 25–40 days depending on automation level and customization depth. Fully automatic models may require additional calibration time.

Can producers customize mesh machine specifications?

Yes, most suppliers support customization of mesh dimensions, wire feed systems, drive motors, control panels, and output configurations. Advanced options include automatic stacking, variable speed drives, and remote diagnostics via IoT-enabled interfaces.

Do suppliers provide technical support and training?

Leading producers offer installation guidance, operator manuals, and remote troubleshooting. Some provide on-site commissioning services at additional cost. Confirm inclusion of technical documentation in English and software interface localization prior to purchase.

Are samples available for testing?

While full machine samples are uncommon, suppliers often allow video demonstrations of running units or dispatch fabricated mesh rolls produced on the same line. Prototype validation through third-party inspection agencies is advisable for large-volume contracts.