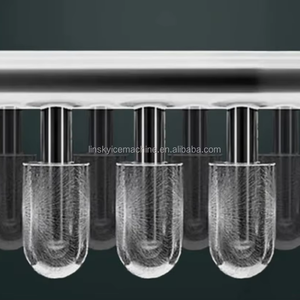

Micro Ice Maker

About micro ice maker

Where to Find Micro Ice Maker Suppliers?

China remains the central hub for micro ice maker manufacturing, with key production clusters concentrated in Guangdong, Zhejiang, and Fujian provinces. These regions host vertically integrated supply chains that specialize in compact refrigeration systems, enabling rapid prototyping and scalable output. The Pearl River Delta, particularly Foshan and Guangzhou, dominates commercial-grade unit production, leveraging proximity to component suppliers for compressors, evaporators, and food-grade stainless steel. Meanwhile, Hangzhou and Ningbo serve as innovation centers for consumer-oriented countertop models, integrating smart controls and energy-efficient thermoelectric cooling technologies.

Manufacturers in these zones benefit from mature ecosystems where injection molding, sheet metal fabrication, and electronic control assembly occur within localized industrial parks. This integration reduces lead times by 20–30% compared to offshore alternatives and supports flexible production runs—from small batches of 100 units to monthly outputs exceeding 10,000 units. Buyers gain access to cost efficiencies driven by localized material sourcing, with aluminum heat exchangers and polypropylene water tanks produced in-line, reducing logistics overhead and inventory holding costs.

How to Choose Micro Ice Maker Suppliers?

Effective supplier selection requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Compliance

Verify adherence to international safety and performance standards, including CE, RoHS, and UL certifications for electrical components. For commercial applications, ensure compliance with NSF/ANSI Standard 7 for food equipment. Request test reports on compressor efficiency, ice yield consistency (measured in kg/24h), and noise levels (should not exceed 45 dB for indoor use).

Production Capability Audits

Assess infrastructure maturity through verifiable metrics:

- Minimum factory area of 3,000m² for sustained volume output

- In-house R&D teams capable of firmware development for smart models

- Integrated quality control lines with leak testing, electrical safety checks, and cycle endurance validation

Cross-reference on-time delivery rates (target ≥99%) and response times (ideally ≤2 hours) as indicators of operational reliability.

Transaction Safeguards

Prioritize suppliers offering third-party transaction protection and documented after-sales service protocols. Evaluate reorder rates as a proxy for customer satisfaction—rates above 20% indicate consistent product quality and support. Conduct sample testing to validate ice clarity, production speed (first batch within 10 minutes), and water consumption efficiency before placing bulk orders.

What Are the Best Micro Ice Maker Suppliers?

| Company Name | Main Products | Price Range (USD) | MOQ | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|

| JS Global Trading Co., Ltd. | Ice Machines, Snack Machines, Electric Grills | $1,200–$3,700 | 1 piece | Data Unavailable | ≤9h | Data Unavailable | Data Unavailable |

| Hangzhou Sino-Cold Sci-Tech Co., Ltd. | Countertop Ice Makers, Portable Units | $54.99–$1,300 | 100 sets / 1 set | 99% | ≤2h | 25% | US $480,000+ |

| Guangzhou Yuelai Yueqiang Machinery Co., Ltd. | Mini, Desktop, Commercial Ice Makers | $27–$1,080 | 1 unit/set | 100% | ≤2h | 22% | US $10,000+ |

| Whalfly Tek Co., Ltd. | Portable, Smart, Bullet-Shaped Ice Makers | $38–$159 | 1 unit / 200 sets | 100% | ≤1h | <15% | US $9,000+ |

| Foshan Libosa Hotel Suppliers Co., Ltd. | Commercial Countertop Ice Makers | $208–$869 | 1 piece/set | 100% | ≤2h | 23% | US $150,000+ |

Performance Analysis

Hangzhou Sino-Cold and Foshan Libosa demonstrate strong commercial positioning with high online revenue and proven reorder rates, indicating market acceptance and reliable fulfillment. Guangzhou Yuelai Yueqiang and Whalfly Tek offer ultra-low MOQs and competitive pricing, ideal for entry-level buyers or niche product testing. Whalfly Tek stands out with sub-1-hour response times, enhancing communication agility. JS Global targets high-end commercial clients with premium-priced units but lacks transparency in delivery and financial metrics. Suppliers with full customization capabilities—including color, logo, packaging, and control panel design—provide added value for branded deployments.

FAQs

How to verify micro ice maker supplier reliability?

Cross-check ISO 9001 certification status and request evidence of product-specific compliance (CE, RoHS). Analyze transaction history, focusing on on-time delivery performance and customer feedback related to product durability and售后 support. Video audits of production lines can confirm in-house manufacturing versus trading practices.

What is the typical sampling timeline?

Standard samples are typically produced within 7–14 days. Customized units with unique molds or control interfaces may require 20–30 days. Air freight adds 5–10 days for international delivery, depending on destination region.

Can suppliers accommodate low-volume or customized orders?

Yes, many manufacturers accept MOQs as low as 1 unit for standard models. Customization options include housing color, branding (logo printing), user interface language, and voltage specifications (110V/220V). Mold modifications for structural changes incur additional fees and longer lead times.

Do suppliers provide OEM/ODM services?

Multiple suppliers listed offer full OEM/ODM support, including PCB design, firmware programming, and packaging development. Minimum order thresholds for ODM projects typically start at 1,000 units, with prototype validation included in the workflow.

What are common payment and shipping terms?

Standard payment methods include T/T, L/C, and platform-backed escrow. Shipping terms range from FOB Guangzhou/Ningbo to CIF destinations worldwide. Sea freight is optimal for container loads, while air freight suits urgent sample or small-batch deliveries.