Microfactory Examples

1/11

1/11

1/9

1/9

1/43

1/43

1/24

1/24

1/3

1/3

1/2

1/2

About microfactory examples

Where to Find Microfactory Examples Suppliers?

Global microfactory solutions are increasingly concentrated in specialized industrial hubs across China, with key suppliers based in Shandong, Guangdong, and Fujian provinces. These regions host vertically integrated manufacturing ecosystems that support rapid prototyping, modular automation, and scalable production lines for niche applications in food processing, lab-on-a-chip systems, and urban agriculture. Shandong-based firms leverage proximity to raw material sources and heavy machinery networks, enabling cost-efficient integration of microwave drying and baking systems. Meanwhile, Guangdong and Fujian clusters excel in high-precision microfluidic device fabrication and smart indoor farming technologies, benefiting from advanced electronics supply chains and export-oriented logistics infrastructure.

Suppliers in these zones offer modular turnkey setups ideal for decentralized production models. The ecosystem supports both capital-intensive industrial microfactories—such as automated nut roasting or tea drying lines—and compact, containerized hydroponic units suitable for urban farms. With factory areas ranging from 500m² to over 24,000m², suppliers demonstrate varying scales of operational maturity. Buyers benefit from localized component sourcing, which reduces lead times by 20–30% compared to offshore alternatives, and enables faster deployment of customized configurations. Average order fulfillment timelines range from 15 to 45 days depending on complexity and equipment type.

How to Choose Microfactory Examples Suppliers?

Effective supplier selection requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Specialization & Application Fit

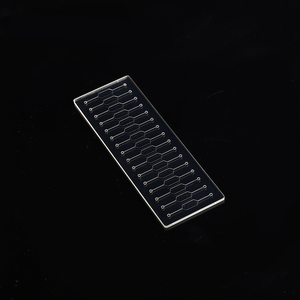

Assess whether the supplier’s product portfolio aligns with your target application—be it food processing (e.g., microwave drying, puffing, baking), biotech (microfluidic chips), or controlled-environment agriculture (hydroponic grow systems). Confirm expertise through documented case studies, OEM customization capabilities, and compatibility with automation controls. For microfluidic devices, verify cleanroom manufacturing standards and material specifications (e.g., PMMA, PDMS).

Production Capacity and Scalability

Evaluate minimum order quantities (MOQs) and pricing structures:

- Industrial-scale equipment (e.g., combi ovens, microwave dryers): MOQs typically start at 1 set; prices range from $9,999 to $75,999

- Modular farming systems: MOQs vary between 1 piece (for full-container units) to 3,000 pieces (for consumer kits); unit costs as low as $8.70

- Microfluidic chips: MOQs from 5 to 10,000 pieces; per-unit pricing between $1.13 and $252 based on complexity

- Cross-reference online revenue indicators (ranging from US $2,000+ to $490,000+) as proxies for market presence and export experience

Quality Assurance and Responsiveness

Prioritize suppliers with verified on-time delivery rates of 100%, response times under 3 hours, and reorder rates indicating customer retention. While formal certifications (ISO, CE) are not explicitly listed in available data, consistent performance metrics suggest adherence to structured quality management practices. Request test reports, equipment schematics, and video audits of production floors to validate process control.

What Are the Best Microfactory Examples Suppliers?

| Company Name | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate |

|---|---|---|---|---|---|---|---|

| Jinan Talin Tech Co., Ltd. | Drying Equipment, Meat Processing, Nuts Machinery | $9,999–$75,999 | 1 set / 1 box | 100% | ≤1h | $2,000+ | <15% |

| HONG KONG EHANG TECHNOLOGY CO., LIMITED | Microfluidic Chips, Lab Supplies | $1.13–$252 | 5–10,000 pcs | 100% | ≤3h | $5,000+ | <15% |

| Foshan Hanyi Technology Ltd | Microwave Ovens, Air Fryers, Combi Ovens | $139–$3,500 | 20–287 units | 100% | ≤2h | $360,000+ | 42% |

| Shenzhen Bingxia Technology Co., Ltd. | Hydroponics, Microgreen Systems, Indoor Farms | $900–$46,888 | 1 piece | 100% | ≤3h | Not specified | - |

| Plant Fun(Xiamen) Co., Ltd | Indoor Garden Kits, Grow Systems, Seed Packs | $5–$62.50 | 1,000–3,000 pcs | 100% | ≤1h | $490,000+ | 23% |

Performance Analysis

Jinan Talin Tech and Foshan Hanyi specialize in industrial thermal processing systems, offering robust microwave and combi oven solutions suited for small-batch food manufacturing. Their high per-unit pricing reflects durable engineering and scalability. In contrast, Plant Fun (Xiamen) and Shenzhen Bingxia focus on agricultural microfactories, providing containerized and modular growing environments ideal for urban farming startups. Notably, Foshan Hanyi stands out with a 42% reorder rate—the highest among listed suppliers—indicating strong customer satisfaction despite higher MOQs. HONG KONG EHANG TECHNOLOGY serves a distinct biotech segment with ultra-low-cost microfluidic chips, enabling R&D teams to prototype diagnostic devices at scale. All top-tier suppliers maintain 100% on-time delivery, underscoring reliable operational execution. Buyers seeking customization should prioritize suppliers offering design flexibility, such as color, labeling, packaging, and hand-assembled components.

FAQs

How to verify microfactory supplier reliability?

Evaluate on-time delivery records, response speed, and verifiable transaction volume. Request facility walkthrough videos, equipment testing protocols, and client references. For food-grade or lab-critical applications, confirm material compliance (e.g., stainless steel construction, medical-grade polymers) even if formal ISO/CE certification is not publicly disclosed.

What is the typical lead time for microfactory equipment?

Standard orders require 15–30 days for production and preparation. Complex systems involving automation integration or custom engineering may extend to 45 days. Air freight adds 5–10 days globally; sea shipping takes 20–35 days depending on destination port congestion.

Can suppliers accommodate custom designs?

Yes, multiple suppliers offer OEM services, including logo printing, color customization, packaging redesign, and functional modifications. Plant Fun and Shenzhen Bingxia explicitly list extensive customization options, while Jinan Talin Tech provides tailored microwave processing parameters for specific food products.

Do suppliers provide samples before bulk orders?

Sample availability depends on product type. For consumable items like seed packs or ceramic grow kits, suppliers may offer small batches at reduced cost. For large-scale machinery, buyers are advised to request demo units or site visits to operational installations instead of physical samples.

Are microfactory systems export-ready?

Most suppliers have established export channels, particularly those with annual online revenues exceeding $360,000. Confirm voltage compatibility, language-specific control panels, and compliance with local electrical and safety codes prior to shipment. FOB terms are common, though some partners support CIF arrangements upon request.