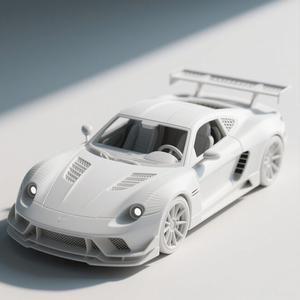

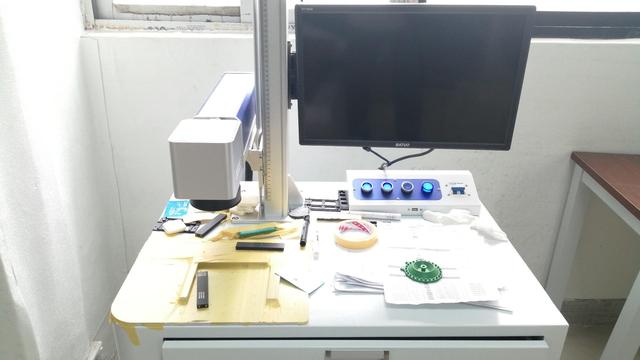

Small Batch Production Examples

About small batch production examples

Where to Find Small Batch Production Suppliers?

China's advanced manufacturing ecosystem supports a robust network of small batch production providers, with key clusters in Shenzhen, Ningbo, and Anqing specializing in rapid prototyping, low-volume fabrication, and custom tooling. These regions host vertically integrated facilities combining CNC machining, 3D printing, vacuum casting, and injection molding—enabling agile responses to prototype and pilot-run demands. Shenzhen leads in high-mix, low-volume electronics and consumer product manufacturing, while Ningbo excels in precision metal components and automotive parts through mature die-casting and machining infrastructure.

Suppliers in these hubs operate flexible production lines optimized for order volumes as low as one piece, supported by digital workflows that reduce setup times and enable same-day prototyping. The integration of CAD/CAM systems with automated quality inspection allows consistent tolerances down to ±0.05mm across material types including ABS, PC, TPU, aluminum alloys, and high-temperature silicones. Buyers benefit from localized supply chains that cut lead times to 7–15 days for prototypes and 15–25 days for initial production runs, with cost advantages of 30–50% over equivalent Western manufacturers.

How to Choose Small Batch Production Suppliers?

Evaluate potential partners using the following technical and operational criteria:

Production & Customization Capability

Confirm access to multi-process manufacturing platforms including CNC milling, SLA/DLP 3D printing, urethane casting, and sheet metal fabrication. Prioritize suppliers offering full-cycle services—from design validation to packaging—with documented capacity for color, texture, labeling, and functional assembly customization. Review STL, CAD, and rendering support to ensure compatibility with your development pipeline.

Quality Control and Compliance

While formal certifications (e.g., ISO 9001) are not universally listed, assess quality performance via verifiable metrics:

- On-time delivery rates exceeding 95%

- Reorder rates above 40% indicating customer retention

- Response times under 2 hours for technical inquiries

Require evidence of in-process inspections, first-article reporting, and post-processing controls such as sandblasting, oxidation, or electroplating verification where applicable.

Minimum Order Quantity and Pricing Flexibility

Most suppliers accommodate MOQs of 1–100 pieces, with competitive unit pricing starting below $1 for resin-based castings and small plastic components. Transparent tiered pricing should reflect volume scaling without hidden tooling fees for non-injection processes. For silicone molds or CNC jobs, confirm whether setup costs are amortized or charged per run.

What Are the Best Small Batch Production Suppliers?

| Company Name | Location | Verified Type | Main Processes | MOQ Range | Price Range (USD) | On-Time Delivery | Avg. Response | Reorder Rate | Annual Online Revenue |

|---|---|---|---|---|---|---|---|---|---|

| Shenzhen Kaier Wo Prototyping Technology Co., Ltd. | Shenzhen, CN | Custom Manufacturer | 3D Print Mold, Vacuum Casting, Plastic Parts | 1 pc | $0.10–12.70 | 100% | ≤2h | 40% | $940,000+ |

| Ningbo Pinshi Technology Co., Ltd. | Ningbo, CN | Not Specified | CNC Machining, Injection Molding, Automotive Parts | 1–100 pcs | $0.90–3,000 | 100% | ≤2h | 50% | $9,000+ |

| Anqing Wayne Hand Model Technology Co., Ltd. | Anqing, CN | Not Specified | Metal 3D Printing, Urethane Casting, Sheet Metal | 1 pc | $3.89–4.70 | 92% | ≤2h | 46% | $240,000+ |

| Shenzhen Yuhan Precision Technology Co., Ltd. | Shenzhen, CN | Multispecialty Supplier | Silicone Molds, Vacuum Casting, Rapid Tooling | 1 pc | $1–50 | 100% | ≤1h | 50% | $20,000+ |

| Yongkang Qucheng Technology Co., Ltd. | Yongkang, CN | Custom Manufacturer | SLA 3D Printing, TPU Parts, Silicone Casting | 1–2 pcs | $1–100 | 99% | ≤2h | 37% | $230,000+ |

Performance Analysis

Shenzhen-based suppliers dominate responsiveness and flexibility, with two vendors achieving sub-2-hour average reply times and 100% on-time fulfillment. Shenzhen Kaier Wo and Shenzhen Yuhan offer broad material adaptability and mold-making expertise critical for iterative design cycles. Ningbo Pinshi stands out for higher-complexity CNC and aluminum alloy processing, though at significantly higher MOQs (100 pieces) for certain services. Despite lower annual revenue, Ningbo Pinshi maintains a 50% reorder rate, suggesting strong client satisfaction in niche engineering applications. Yongkang Qucheng provides extensive customization options—including plating, coloring, and reverse modeling—making it suitable for aesthetic or consumer-facing prototypes.

FAQs

How to verify small batch production supplier reliability?

Assess consistency through on-time delivery records (>95%), reorder rates (>40%), and response speed. Request sample parts to validate dimensional accuracy, surface finish, and material compliance. Verify process documentation for critical steps like mold creation, curing cycles, or CNC toolpath optimization.

What is the typical lead time for small batch orders?

Prototypes and single-piece runs typically ship within 3–7 days. Low-volume production (10–100 units) takes 7–15 days depending on post-processing requirements. Add 5–10 days for international express delivery.

Can suppliers handle full product lifecycle support?

Top-tier providers support concept modeling, rapid prototyping, design iteration, and small-scale manufacturing under one roof. Confirm availability of CAD/STL analysis, DFM feedback, and packaging integration before engagement.

Do manufacturers charge for samples or molds?

Most suppliers include first-article samples within production pricing for orders ≥10 units. For vacuum casting or silicone tooling, expect one-time mold fees ranging $50–$500 unless explicitly waived for qualified buyers.

How to initiate a customized small batch order?

Submit detailed specifications including 3D files (STL, STEP), material preferences, color/Pantone codes, tolerance requirements, and finishing instructions. Reputable suppliers respond with feasibility assessments and quotations within 24 hours.