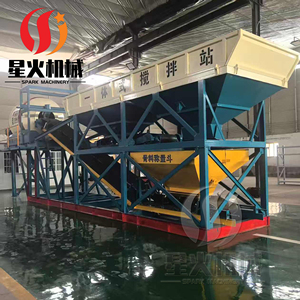

Batch Production System Example

CN

CN

CN

CN

About batch production system example

Where to Find Batch Production System Suppliers?

China remains the global epicenter for batch production system manufacturing, with key industrial hubs concentrated in Shandong and Henan provinces. These regions host vertically integrated facilities capable of delivering standardized and custom-configured batching systems for concrete, asphalt, and dry-mix applications. Shandong's machinery corridor—centered on Jining and Qingdao—features suppliers with access to heavy steel supply chains, reducing material costs by 15–20% compared to non-integrated producers. Henan, home to over half of China’s construction equipment manufacturers, leverages Zhengzhou’s multimodal logistics network to enable rapid dispatch across domestic and export markets.

The clustering effect supports economies of scale, with many suppliers operating end-to-end production lines encompassing structural fabrication, control system integration, and final assembly within co-located facilities. This integration enables lead times as short as 30 days for standard configurations. Buyers benefit from localized ecosystems where component sourcing, technical engineering, and freight coordination occur within tight geographic radii, ensuring responsiveness and flexibility for both bulk orders and engineered-to-order systems.

How to Choose Batch Production System Suppliers?

Selecting reliable partners requires a structured evaluation of technical, operational, and transactional indicators:

Quality Management Verification

Confirm adherence to ISO 9001 standards for quality management systems. For shipments to regulated markets (EU, North America), CE marking is essential for compliance with safety and electromagnetic compatibility directives. Request documentation validating PLC control systems, sensor calibration, and motor performance under industrial load conditions.

Production Infrastructure Assessment

Evaluate supplier capability through verifiable metrics:

- Minimum factory footprint of 5,000m² to support full-line assembly

- In-house design teams specializing in automation and modular integration

- Integrated CNC machining, welding, and electrical panel fabrication

Cross-reference these capabilities with on-time delivery performance (target ≥97%) and response time benchmarks (≤4 hours) to assess operational reliability.

Procurement Risk Mitigation

Utilize secure payment mechanisms such as escrow services that release funds only after equipment verification. Prioritize suppliers with transparent transaction histories, including reorder rates and dispute resolution records. Pre-shipment inspection protocols should include functional testing of batching accuracy, conveyor throughput, and control interface responsiveness. For critical deployments, request remote video audits of production progress or factory acceptance tests.

What Are the Leading Batch Production System Suppliers?

| Company Name | Location | Verified Status | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Product Range |

|---|---|---|---|---|---|---|---|---|

| Pacific Machinery Technology (Shandong) Co., Limited | Shandong, CN | Multispecialty Supplier | US $620,000+ | 100% | ≤3h | 100% | Yes | Fully automatic precast, portable dry-mix, modular stationary plants |

| Zhengzhou Shanghe Construction Machinery Co., Ltd. | Henan, CN | - | US $1,000+ | 100% | ≤2h | <15% | No | Mini asphalt, HZS series batching plants, 25–120m³/h capacity |

| Zhengzhou Hamac Automation Equipment Co., Ltd. | Henan, CN | Brand Holder | US $160,000+ | 100% | ≤2h | <15% | Yes | Modular ready-mix, mobile skip-type, 120m³ dry-batch systems |

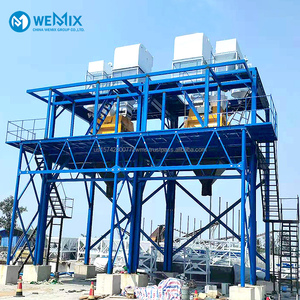

| China Wemix Group Americas Branch LLC | - | - | - | - | ≤4h | - | No | Electric small-scale HZS25, 90m³/h batching systems |

| Shandong Guancheng Machinery Technology Co., Ltd. | Shandong, CN | Custom Manufacturer | - | 100% | ≤1h | <15% | Yes | PLC-controlled 180m³/h systems, compact automatic mixers, prefabricated mini stations |

Performance Analysis

Pacific Machinery stands out with a 100% reorder rate and robust customization capabilities, indicating high client retention and engineering agility. Shandong-based Guancheng Machinery offers the fastest average response time (≤1 hour), ideal for urgent procurement cycles. While several Henan suppliers demonstrate strong technical output, their lower reorder rates suggest potential gaps in post-sale support or long-term reliability. Suppliers offering modular and portable designs—such as mobile skip-type or containerized units—cater effectively to temporary site deployments. For large-scale installations, prioritize vendors with proven experience in PLC-controlled automation and full-line integration.

FAQs

What are typical MOQ and pricing ranges for batch production systems?

Minimum order quantities typically start at 1 set, with prices ranging from $1,999 for mini 25m³/h units to over $147,000 for fully automated 180m³/h systems. Modular and portable variants generally fall between $10,000 and $30,000 per unit.

How long is the average lead time?

Standard systems ship within 30–45 days after order confirmation. Custom-engineered solutions may require 60–75 days, depending on control system complexity and structural modifications.

Can suppliers customize batching systems?

Yes, select manufacturers offer configuration options including color, material feed type (belt vs. screw conveyor), control panel language, logo branding, and packaging. Full automation integration with level transmitters, aggregate scaling, and remote monitoring is available through verified custom manufacturers.

Do batch production systems comply with international standards?

Compliance varies by supplier. Verify CE certification for European market entry and ensure electrical components meet IEC standards. Request test reports for mixer efficiency, weighing accuracy (±1% tolerance), and structural weld integrity.

What logistical support do suppliers provide?

Most suppliers support FOB and CIF shipping terms, with sea freight recommended for cost efficiency on full-container loads. Buyers should confirm packaging methods (disassembled vs. skid-mounted) and destination handling requirements for crane-assisted unloading.