Batch Process Manufacturing Examples

About batch process manufacturing examples

Where to Find Batch Process Manufacturing Suppliers?

China remains a central hub for batch process manufacturing, with specialized industrial clusters in Fujian, Guangdong, and Zhejiang provinces driving efficiency and technical specialization. Xiamen and Ningbo host high-density networks of precision engineering firms offering end-to-end batch production services, from CNC machining to vacuum casting. These regions benefit from mature supplier ecosystems—integrating raw material sourcing, tooling, and logistics—within compact geographic zones, enabling rapid prototyping and scalable mid-volume output.

Suppliers in these clusters operate vertically integrated facilities capable of handling small to medium batch sizes (1–500+ units) with consistent quality control. The proximity of component vendors, mold makers, and testing labs within 30–50km radii reduces lead times by up to 40% compared to decentralized production models. Buyers gain access to flexible manufacturing systems optimized for iterative design validation and low-volume commercial runs, particularly in sectors such as medical devices, automation components, and consumer electronics.

How to Choose Batch Process Manufacturing Suppliers?

Effective supplier selection requires structured evaluation across three critical dimensions:

Production & Technical Capability

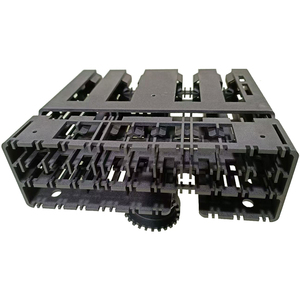

Confirm the supplier’s capacity to execute specific batch processes such as CNC milling, turning, 3D printing, or vacuum casting. Prioritize partners with documented experience in your target material—common options include aluminum, stainless steel, ABS, and silicone. Evaluate infrastructure through verifiable metrics: minimum facility size of 2,000m², presence of multi-axis CNC machines (3-axis and above), and in-house tooling or rapid prototyping units. Cross-reference equipment lists with on-time delivery performance (target ≥95%) to assess operational reliability.

Quality Assurance & Compliance

While formal certifications like ISO 9001 are not universally listed, consistent quality is indicated by reorder rates exceeding 45% and response times under 2 hours. Look for suppliers that offer inspection reports, first-article testing, and material traceability. For export-bound components, ensure compatibility with international standards such as RoHS for electronics or FDA-grade materials for medical applications. Vacuum casting providers should demonstrate PU resin compatibility and dimensional accuracy within ±0.1mm.

Customization & Transaction Security

Most batch manufacturers support full customization—from geometry and surface finish to color, labeling, and packaging. Verify digital workflow integration, including CAD/CAM file acceptance and DFM feedback turnaround (ideally within 24 hours). Use secure transaction methods where available, especially for initial orders. Request physical or digital samples before scaling production; average sampling lead time ranges from 5–12 days depending on complexity.

What Are the Best Batch Process Manufacturing Suppliers?

| Company Name | Location | Main Services | Online Revenue | On-Time Delivery | Response Time | Reorder Rate | Product Listings | MOQ Range |

|---|---|---|---|---|---|---|---|---|

| Xiamen Fuhongzhou Machinery Co., Ltd. | Fujian, CN | CNC Machining, Milling, Turning, Sheet Metal | US $130,000+ | 81% | ≤2h | 36% | 1,170+ | 1 pc |

| Ningbo Pinshi Technology Co., Ltd. | Zhejiang, CN | 3D Printing, Product Design, CNC | US $10,000+ | 100% | ≤2h | 50% | 106+ | 1–100 pcs |

| Shenzhen Yuhan Precision Technology Co., Ltd. | Guangdong, CN | Vacuum Casting, Small-Batch Plastic Parts | US $20,000+ | 100% | ≤1h | 50% | 5+ | 1 pc |

| Shenzhen GH Prototype Technology Co., Ltd | Guangdong, CN | Vacuum Casting, 3D Printing, Machining | US $10,000+ | 100% | ≤2h | 50% | 751+ | 1–2 pcs |

| Dongguan Dafeng Model Co., Ltd. | Guangdong, CN | Machining, Molding, 3D Printing, Casting | US $140,000+ | 87% | ≤6h | 46% | 2,720+ | 1–500 pcs |

Performance Analysis

Suppliers like Shenzhen Yuhan and Ningbo Pinshi achieve 100% on-time delivery and high reorder rates, indicating strong process discipline and customer satisfaction. Rapid response times (≤1h) correlate with proactive order management, particularly beneficial for urgent revisions or expedited batches. Xiamen Fuhongzhou and Dongguan Dafeng offer broad service portfolios and higher transaction volumes, making them suitable for diversified sourcing needs. However, their lower reorder rates suggest potential gaps in post-sale engagement or consistency. For precision metal parts, prioritize CNC-dedicated shops with unit pricing below $0.80 and MOQs starting at 1 piece. For plastic prototypes and small-series runs, vacuum casting specialists provide cost-effective alternatives with fast turnaround (5–8 days typical).

FAQs

What is the typical MOQ for batch process manufacturing?

Minimum Order Quantities range from 1 to 500 pieces, depending on process and material. CNC machining and 3D printing commonly support single-piece orders, while vacuum casting and injection molding may require 10–100 units to justify tooling costs.

How long does batch production take?

Standard lead times vary: 7–10 days for CNC-machined or 3D-printed parts; 5–8 days for vacuum-cast components. Complex geometries or surface treatments (e.g., anodizing, powder coating) may extend timelines by 3–5 days.

Do suppliers offer design for manufacturability (DFM) feedback?

Yes, most established providers deliver DFM analysis within 24 hours of receiving CAD files. This includes recommendations on draft angles, wall thickness, tolerance stack-up, and material selection to reduce defects and costs.

Can I get customized finishes or branding?

Full customization is standard. Options include color dyeing, laser engraving, logo embossing, packaging labeling, and graphic application. Confirm material compatibility—e.g., ABS accepts painting better than PLA in 3D-printed parts.

Are samples available before full production?

Yes, functional or appearance samples are typically offered. Costs range from $0.10 to $100 depending on complexity. Sampling fees may be credited toward bulk orders. Allow 5–12 days for sample creation and shipping.