Batch Manufacturing Examples

About batch manufacturing examples

Where to Find Batch Manufacturing Examples Suppliers?

Global batch manufacturing services are concentrated in specialized industrial hubs across China, particularly in Guangdong and Henan provinces. Dongguan and Shenzhen in Guangdong serve as core centers for precision machining and small-batch prototyping, hosting vertically integrated facilities capable of rapid turnaround for metal, plastic, and composite components. These regions benefit from mature supply chains for raw materials and tooling, enabling cost efficiencies of 20–35% compared to Western contract manufacturers. Henan Province, notably Zhengzhou, specializes in large-scale industrial batching systems such as concrete and asphalt mixing plants, leveraging localized heavy machinery ecosystems and steel production networks.

The clustering supports both low-volume custom production and high-volume repeat runs. Suppliers in these zones offer scalable capacity with average monthly outputs ranging from 10,000 to over 500,000 units depending on complexity. Buyers gain access to multi-process workshops equipped with CNC turning, milling, 3D printing, vacuum casting, and sheet metal fabrication—often within a single facility. This integration reduces lead times by up to 40%, with standard sample delivery achievable in 7–14 days and bulk production cycles typically completed within 25–45 days.

How to Choose Batch Manufacturing Examples Suppliers?

Selecting reliable partners requires systematic evaluation based on technical capability, quality assurance, and transactional reliability:

Production & Material Capabilities

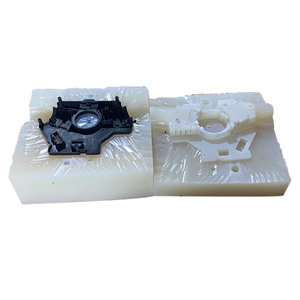

Confirm compatibility with required materials: common options include brass, copper, stainless steel, bronze, engineering plastics, and silicone. Assess whether the supplier operates in-house CNC lathes, milling machines, or molding equipment. For electronic or resin-based prototypes, verify availability of 3D printing and vacuum casting infrastructure.

Quality Management Systems

While formal certifications (e.g., ISO 9001) are not universally listed, performance indicators such as on-time delivery rates exceeding 94% and reorder rates above 50% signal operational consistency. Prioritize suppliers with documented process controls, especially for repeatable batch runs requiring tight tolerances (±0.01mm typical for precision machining).

Order Flexibility & Scalability

Evaluate minimum order quantities (MOQs), which vary significantly:

- Precision machined parts: MOQ as low as 1 piece

- Action figures/resin crafts: Typically 200+ sets

- Industrial batching plants: Sold per set (MOQ = 1)

- Sheet metal or molded components: Often require 100-piece minimums

Customization depth should also be assessed—some suppliers support full design iteration, color/labeling options, and packaging modifications, while others operate on fixed configurations.

What Are the Best Batch Manufacturing Examples Suppliers?

| Company Name | Main Products | Monthly Output Capacity | On-Time Delivery | Avg. Response Time | Reorder Rate | Typical MOQ | Price Range (USD) | Core Markets |

|---|---|---|---|---|---|---|---|---|

| Dongguan Kaizhida Precision Machinery Co., Ltd. | CNC Machining Services (507 listings) | 50,000–80,000 units | 100% | ≤1 hour | Not specified | 1 piece | $0.10–0.80 | Automotive, Industrial Equipment |

| Zhengzhou Hamac Automation Equipment Co., Ltd. | Concrete Batching Plants | 10–15 sets/month | 100% | ≤2 hours | <15% | 1 set | $10,000–19,800 | Construction, Infrastructure |

| Dongguan New Creation Technology Company Limited | Resin Crafts, Small-Batch Electronics (454 listings) | 10,000–20,000 units | 94% | ≤4 hours | 50% | 1–200 sets | $0.90–60 | Consumer Goods, Collectibles |

| Henan ZOOMLINE Machinery Co., Ltd. | Asphalt Mixers, Concrete Plants (439 listings) | 5–8 sets/month | 100% | ≤4 hours | 100% | 1 set | $80,000–$450,000 | Heavy Construction, Government Projects |

| Shenzhen Shan Bo Industrial Co., Ltd. | Machining, Moulds, Sheet Metal (81+ listings) | 30,000–60,000 units | 100% | ≤2 hours | Not specified | 100 pieces | $0.10–$1,000 | Electronics, OEM Components |

Performance Analysis

Dongguan- and Shenzhen-based suppliers excel in agile, low-MOQ manufacturing suitable for prototyping and niche product development. Their sub-2-hour response times and high on-time delivery rates reflect optimized digital workflows ideal for fast-turnaround sourcing. In contrast, Henan’s industrial manufacturers focus on capital-intensive batching systems, where 100% reorder rates (as seen with Henan ZOOMLINE) indicate strong client retention in long-cycle infrastructure projects. Suppliers offering under-$1 component pricing typically serve high-volume OEMs, whereas those handling $10k+ machinery emphasize engineering validation and site-specific customization.

FAQs

What is the typical lead time for batch manufacturing samples?

For machined or molded components, samples can be produced in 5–10 days. Larger systems like concrete or asphalt batching plants require 20–30 days due to structural assembly and testing protocols. Shipping via express courier adds 3–7 days internationally.

Are free samples available?

Some suppliers offer paid samples refundable against future orders. Low-cost components (under $5) may incur full sample charges, while complex prototypes or machinery demos are typically quoted separately.

Can suppliers handle full turnkey production?

Yes, leading providers manage end-to-end processes including design validation, material procurement, production, quality inspection, and export packaging. Confirmation of in-house tooling and testing capabilities is recommended before engagement.

Do batch manufacturers support private labeling?

Many allow logo imprinting, custom packaging, and color specification, particularly in consumer-facing categories like action figures or decorative metalwork. Industrial equipment suppliers may offer branding panels or control interface customization.

What payment and transaction safeguards exist?

Buyers should utilize secure payment methods with escrow functionality. Review historical transaction volumes and dispute resolution records where available. Pre-shipment inspections are advised for high-value machinery to verify compliance with technical specifications.