Assembling Manufacturing Process Examples

1/13

1/13

1/18

1/18

CN

CN

1/30

1/30

About assembling manufacturing process examples

Where to Find Assembling Manufacturing Process Suppliers?

China remains the global epicenter for assembling manufacturing process equipment, with key industrial hubs in Zhejiang, Henan, and Guangdong provinces driving innovation and scale. Zhejiang's Ningbo-Yuyao corridor specializes in automation integration, offering modular assembly systems for consumer electronics and home appliances. Henan’s Zhengzhou cluster focuses on heavy industrial lines—including automotive and commercial vehicle production—with proximity to steel and metal fabrication zones reducing component lead times by 18–25%. Guangdong’s Huizhou-Dongguan region excels in high-precision, fast-cycle assembly systems for white goods and lithium-ion battery packs, supported by mature supply chains for motors, conveyors, and control systems.

These regional ecosystems enable vertically integrated production, where suppliers manage design, machining, assembly, and testing under one roof. Buyers benefit from compressed development cycles (average 30–45 days for standard lines), cost efficiencies (20–35% below Western OEMs), and access to specialized engineering talent. The concentration of automation specialists, material handling vendors, and PLC integrators within 50km radii ensures rapid prototyping and after-sales support, making these clusters ideal for both turnkey solutions and custom configurations.

How to Choose Assembling Manufacturing Process Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical & Engineering Capabilities

Prioritize suppliers with demonstrated expertise in automated assembly systems, including robotic integration, conveyor synchronization, and inline quality inspection. Confirm experience with relevant product categories—such as household appliances, automotive components, or electronics—through project portfolios or video demonstrations. For high-volume applications, verify use of PLC-controlled sequencing, servo-driven positioning, and error-proofing mechanisms (poka-yoke).

Production Infrastructure Assessment

Evaluate core operational metrics:

- Minimum factory area of 3,000m² to support full-line fabrication

- In-house capabilities in CNC machining, welding, and electrical panel assembly

- Dedicated R&D teams focused on process optimization and energy efficiency

Cross-reference response times (target ≤5 hours) and on-time delivery rates (ideal ≥97%) as indicators of operational stability and customer service priority.

Quality Assurance & Compliance

Require ISO 9001 certification as a baseline for quality management. For export markets, CE marking is essential for compliance with EU machinery directives. Request documentation on component sourcing, electrical safety standards (e.g., IEC 60204), and functional test protocols. Third-party audits or facility walkthroughs can validate adherence to structured quality control procedures.

Transaction Security & After-Sales Support

Utilize secure payment methods with milestone-based releases tied to production phases. Confirm post-delivery support, including installation supervision, operator training, and spare parts availability. Analyze reorder rates as a proxy for customer satisfaction—suppliers with rates above 35% typically offer robust reliability and service responsiveness.

What Are the Best Assembling Manufacturing Process Suppliers?

| Company Name | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options |

|---|---|---|---|---|---|---|---|

| Yuyao Zhiheng Automation Equipment Co., Ltd. | Assembly Line, Automatic Handle Machine | $5,000–60,000 | 1 set | 100% | ≤5h | - | Limited (based on tags) |

| Zhengzhou Duoyuan Intelligent Equipment Co., Ltd. | Automotive Assembly Lines, Battery Production Systems | $35,300–256,800 | 1 piece/set | 100% | ≤8h | - | High (industrial-scale customization) |

| Huizhou Guanjie Technology Co., Ltd. | Washing Machine, Refrigerator Assembly Lines | $30,000–180,000 | 1 set | 100% | ≤2h | - | Moderate (conveyor, coating, handling integration) |

| Xiamen Yistar Precision Manufacturing Co., Ltd. | Custom Stamping, Machined Parts, Hardware Components | $0.50–15 | 1 piece | 97% | ≤3h | 39% | Extensive (material, size, logo, packaging) |

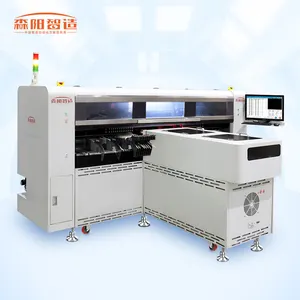

| Morel Equipments Co., Ltd. | SMT, PCB, LED Bulb Assembly Lines | $9,999–34,999 | 1 set | 100% | ≤2h | 50% | High (automation level, speed, fixture design) |

Performance Analysis

High-volume system integrators like Zhengzhou Duoyuan and Huizhou Guanjie dominate complex industrial assembly projects, offering end-to-end lines for automotive and appliance manufacturing at competitive price points. Their 100% on-time delivery records reflect strong project management and supply chain coordination. Morel Equipments stands out in electronics assembly with a 50% reorder rate, indicating strong customer retention driven by responsive engineering and proven machine performance. Xiamen Yistar offers granular customization for component-level assembly needs, backed by a verified 39% reorder rate and sub-$15 unit pricing. Yuyao Zhiheng provides entry-level automation solutions with rapid response times, suitable for SMEs exploring initial automation adoption.

FAQs

What are typical MOQs for assembly line systems?

Most suppliers require a minimum order of 1 set for complete assembly lines or machines. Component-level suppliers (e.g., precision machined parts) may accept orders starting at 1 piece, especially for prototyping or replacement parts.

How long do assembly line projects take to deliver?

Standard systems typically ship within 30–45 days after order confirmation. Customized or large-scale lines (e.g., full refrigerator or EV battery assembly) may require 60–90 days depending on complexity, automation level, and testing requirements.

Can suppliers customize assembly processes?

Yes, most established suppliers offer extensive customization in layout, cycle time, automation grade, and integration with existing ERP/MES systems. Providers like Morel Equipments and Xiamen Yistar explicitly list technical drawings, laser marking, and fixture design as configurable options.

Do suppliers provide installation and training?

Reputable manufacturers typically include remote guidance and documentation. On-site installation and operator training are often available upon request, sometimes included in premium packages or negotiated separately based on project scope.

Are there cost advantages in consolidating component and line sourcing?

Yes. Suppliers with in-house machining, stamping, and conveyor production (e.g., Huizhou Guanjie, Xiamen Yistar) can reduce system costs by 10–15% through vertical integration. Consolidating part fabrication and final assembly with a single vendor also simplifies logistics and quality traceability.