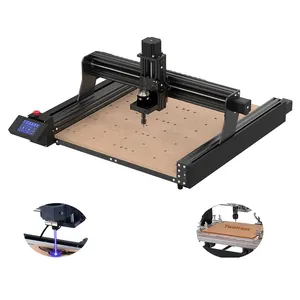

Mini Cnc Machine

Top sponsor listing

Top sponsor listing

About mini cnc machine

Where to Find Mini CNC Machine Suppliers?

China remains the central hub for mini CNC machine manufacturing, with key production clusters in Shandong, Jiangsu, and Fujian provinces. These regions host vertically integrated supply chains that support rapid prototyping and cost-efficient mass production. Shandong is particularly notable for its concentration of precision machinery manufacturers, offering access to advanced CNC milling and turning facilities. Jiangsu-based suppliers benefit from proximity to major ports like Shanghai, enabling faster export logistics, while Fujian’s Quanzhou zone specializes in compact industrial equipment tailored for small-scale workshops and educational institutions.

The regional ecosystems enable tight coordination between component suppliers—such as spindle, guide rail, and control system providers—and final assembly units, often within a 30–50 km radius. This integration reduces lead times by up to 25% compared to fragmented supply networks. Buyers can expect standard delivery windows of 15–30 days for non-customized units, with localized sourcing cutting production costs by 15–30% versus equivalent Western-made machines. The availability of modular designs further supports scalability for both low-volume buyers and large distributors.

How to Choose Mini CNC Machine Suppliers?

Effective supplier selection requires structured evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

Confirm alignment with functional requirements: axis configuration (3-axis vs. 4/5-axis), working area dimensions (e.g., 3040, 6040, 1325 models), spindle power (typically 0.8–2.2kW), and control systems (DSP, Mach3, or closed-loop servo). Prioritize suppliers offering documented compatibility with common CAD/CAM software suites. For international compliance, verify CE marking and adherence to IEC 60204-1 safety standards for electrical systems.

Production Infrastructure Assessment

Evaluate core manufacturing assets:

- Minimum factory footprint of 3,000m² indicating capacity for batch production

- In-house machining capabilities including CNC lathes and milling centers

- Dedicated quality testing stations for dimensional accuracy and runout calibration

Cross-reference declared output volumes with online revenue metrics and on-time delivery performance (target ≥95%) to assess fulfillment reliability.

Customization & Support Evaluation

Assess flexibility in motor type (stepper vs. servo), tooling options (T-slot table, vacuum fixtures), cooling method (air or water), and automation features (ATC, linear guides). Require evidence of after-sales support structures—such as remote diagnostics or spare parts availability—before contract finalization. Use sample orders to validate build quality, focusing on frame rigidity, noise levels, and positioning repeatability under load.

What Are the Best Mini CNC Machine Suppliers?

| Company Name | Location | Main Products (Listings) | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options |

|---|---|---|---|---|---|---|---|

| Shandong Youhao Energy Technology Co., Ltd. | Shandong, CN | Multifunctional 3040/4060, 4-Axis, 6090 Router | US $280,000+ | 100% | ≤1h | 25% | Motor, ATC, cooling, rails, control system, vacuum |

| Jinan Chentuo Cnc Equipment Co., Ltd. | Shandong, CN | Iron-Casting Body Milling, 6040 Router, ATC Models | US $300,000+ | 100% | ≤3h | 21% | Servo motors, linear guides, pneumatic tool change, spindle power |

| Tengzhou Believe Machinery Co., Ltd. | Shandong, CN | M300/M350 Milling, XK7110, VMC215 Machining Center | US $10,000+ | 100% | ≤3h | 16% | Limited customization indicated |

| Changzhou Handi Motor Science And Technology Co., Ltd. | Jiangsu, CN | Mini 3020/3040/6040 Milling & Routers | US $40,000+ | 100% | ≤4h | 23% | Basic model variations; spindle and size options |

| Quanzhou Chuanzhou Import & Export Trading Co., Ltd. | Fujian, CN | CNC Lathe (primary), limited mini CNC presence | US $6,000+ | 50% | ≤2h | 100% | No explicit customization data available |

Performance Analysis

Shandong-based suppliers dominate in both volume and customization depth. Jinan Chentuo and Shandong Youhao lead in export performance, with verified revenues exceeding US$280,000 annually and full compliance with on-time delivery benchmarks. Their offerings span entry-level hobbyist machines to industrial-grade routers with automated tool changers and high-torque spindles. Tengzhou Believe and Changzhou Handi provide competitively priced standard models, suitable for buyers prioritizing reliability over advanced features. Notably, Quanzhou Chuanzhou reports a 100% reorder rate despite a 50% on-time delivery record, suggesting niche market alignment but potential logistical constraints. Response times across top-tier suppliers average under 3 hours, with Shandong companies demonstrating superior responsiveness critical for iterative procurement cycles.

FAQs

How to verify mini CNC machine supplier reliability?

Validate ISO 9001 certification status through accredited registrars. Request factory audit reports or video walkthroughs confirming CNC machining centers, welding bays, and quality inspection lines. Analyze transaction history for consistency in order fulfillment and dispute resolution outcomes.

What is the typical MOQ and lead time?

Most suppliers offer a minimum order quantity of 1 unit, facilitating pilot testing. Standard lead time ranges from 15 to 25 days post-payment confirmation. Custom configurations involving servo systems or automatic tool changers may extend timelines to 35–45 days.

Can mini CNC machines be customized for specific materials?

Yes, reputable suppliers adjust spindle RPM, feed rates, and rigidity profiles based on target materials—wood, acrylic, aluminum, or PCBs. Specify required cutting depth, tool diameter, and material clamping method during inquiry to receive technically matched proposals.

Do suppliers provide control system training or technical documentation?

Leading suppliers include multilingual operation manuals, wiring diagrams, and G-code compatibility guides. Some offer remote setup assistance via TeamViewer or similar platforms. Confirm inclusion of software licenses (e.g., Mach3, UGS) prior to purchase.

What are common packaging and shipping methods?

Machines are typically crated in wooden enclosures with foam padding and moisture barriers. Sea freight (LCL/FCL) is standard for bulk shipments; air freight options exist for single units requiring urgent delivery. Confirm FOB, CIF, or DDP terms during negotiation to clarify liability and customs responsibilities.