Mini Hollow Block Making Machine

Top sponsor listing

Top sponsor listing

1/12

1/12

1/18

1/18

1/19

1/19

1/25

1/25

1/28

1/28

1/12

1/12

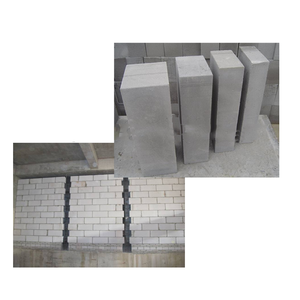

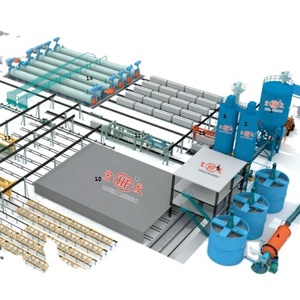

About mini hollow block making machine

Where to Find Mini Hollow Block Making Machine Suppliers?

China remains the dominant global hub for mini hollow block making machine manufacturing, with key supplier clusters concentrated in Shandong and Henan provinces. These regions host vertically integrated industrial ecosystems that combine raw material processing, component fabrication, and final assembly under one supply chain. Shandong’s Jining and Qingdao zones specialize in hydraulic-driven, semi-automatic models, leveraging proximity to steel foundries to reduce material costs by 15–20%. Meanwhile, Zhengzhou in Henan serves as a logistics and production nexus, housing over half of China’s brick and block machinery exporters, enabling faster dispatch and consolidation for international shipments.

The regional infrastructure supports rapid scalability, with suppliers operating facilities exceeding 5,000m² on average and maintaining in-house mold design, welding, and testing units. This integration translates into lead times of 20–40 days for standard configurations and MOQs as low as one unit. Buyers benefit from competitive pricing—ranging from $80 for manual models to $3,700 for high-capacity semi-auto systems—and access to modular designs suitable for small-scale construction projects or rural development initiatives.

How to Choose Mini Hollow Block Making Machine Suppliers?

Effective supplier selection requires structured evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

Confirm whether suppliers offer customization for block dimensions (typically 4–6 inch hollow formats), vibration frequency settings, and hydraulic pressure ranges (6–12 MPa). Verify compatibility with common raw materials such as concrete mix, fly ash, and cement-soil blends. For export compliance, ensure machines meet CE or equivalent safety standards, particularly for electrical components and moving parts.

Production & Quality Assurance Assessment

Evaluate supplier infrastructure through available indicators:

- On-time delivery rate ≥95% indicates reliable production scheduling

- In-house R&D or engineering teams capable of adapting mold designs and power sources (electric/diesel)

- Integration of quality control checkpoints for weld integrity, mold alignment, and vibration stability

Prioritize suppliers with documented testing procedures and response times under 2 hours, signaling operational responsiveness.

Procurement Risk Mitigation

Utilize secure payment terms such as escrow services until post-arrival performance verification. Request product videos or facility walkthroughs to validate claims about automation level and build quality. Conduct sample testing to assess block density, dimensional accuracy, and cycle time before scaling orders. Analyze reorder rates—those above 25% suggest customer satisfaction and consistent output quality.

What Are the Best Mini Hollow Block Making Machine Suppliers?

| Company Name | Main Products | Customization Options | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Verified Type |

|---|---|---|---|---|---|---|---|

| Shandong Hongfa Scientific Industrial And Trading Co., Ltd. | Brick/Tile/Pipe Making Machinery, Concrete Mixers | Block size, color, logo, power source, mold shape, packaging | US $390,000+ | 100% | ≤2h | 66% | Custom Manufacturer |

| Zhengzhou Summit Trading Co., Ltd. | Brick Making Machinery, Sand Equipment, Loaders | Limited customization per listing | US $50,000+ | 100% | ≤1h | 25% | Not Specified |

| Changge Hengruide Machinery Equipment Co., Ltd. | Other Construction Machinery, Crusher, Mining Equipment | Basic model variants only | US $10,000+ | 100% | ≤1h | 16% | Not Specified |

| SUMU (Shanghai) Automation Engineering Co., Ltd. | Brick Making Machinery, Concrete Mixers | Manual/auto variants, interlocking clay blocks | US $10,000+ | 100% | ≤2h | 20% | Not Specified |

| Linyi Fulang Machinery Co., Ltd. | Brick Making Machinery, Pavers | Color, size, logo, packaging, graphic design | US $20,000+ | 85% | ≤2h | <15% | Multispecialty Supplier |

Performance Analysis

Shandong Hongfa stands out with the highest online revenue (US $390,000+) and a 66% reorder rate, indicating strong market trust and repeat business—likely driven by extensive customization options and diversified product lines. All top-tier suppliers maintain 100% on-time delivery except Linyi Fulang, whose 85% rate may signal capacity constraints despite offering branding personalization. Zhengzhou Summit and Changge Hengruide demonstrate fast response times (≤1h), reflecting efficient customer service operations typical of Henan-based exporters. Buyers seeking turnkey solutions should prioritize manufacturers with in-house molds, hydraulic station integration, and conveyor system compatibility.

FAQs

How to verify mini hollow block making machine supplier reliability?

Cross-check stated certifications (e.g., ISO, CE) with official registries. Request evidence of quality control processes, including weld inspections and load testing. Review transaction metrics such as on-time delivery, reorder rate, and response speed—suppliers with reorder rates above 25% typically deliver consistent product quality and service.

What is the typical lead time and MOQ?

Standard lead times range from 20 to 40 days after order confirmation. Minimum Order Quantities vary: many suppliers accept single-unit orders for manual or portable models, while semi-automatic systems may require 1–4 sets depending on configuration.

Can suppliers customize machine specifications?

Yes, leading suppliers offer adjustments to block dimensions (e.g., 4", 6" hollow), mold layout (single or multi-cavity), power source (single-phase, three-phase, diesel), and auxiliary components like conveyors or silos. Custom branding, color schemes, and user manuals in local languages are also commonly available.

Do manufacturers support global shipping?

Most established suppliers have export experience and manage FOB, CIF, or DAP shipping terms. They coordinate container loading, documentation, and customs clearance for machinery transport via sea freight, which is optimal for bulk orders. Air freight is viable for urgent samples or single units.

Are samples available before bulk ordering?

Sample policies differ. Some suppliers provide functional units for testing at full cost, with partial reimbursement upon order placement. Others offer digital simulations or video demonstrations of machine operation. For physical samples, expect production and shipping timelines of 10–25 days depending on complexity.