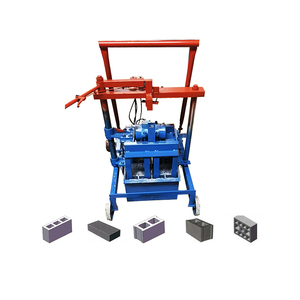

Mini Concrete Block Making Machine

1/18

1/18

1/25

1/25

1/9

1/9

1/28

1/28

1/12

1/12

1/12

1/12

About mini concrete block making machine

Where to Find Mini Concrete Block Making Machine Suppliers?

China remains the central hub for mini concrete block making machine production, with key manufacturing clusters in Hebei, Henan, and Shandong provinces. These regions host vertically integrated facilities that streamline component sourcing, assembly, and export logistics. Hebei and Henan alone account for over 70% of China’s brick machinery exporters, supported by mature supply chains for steel molds, hydraulic systems, and vibration motors. Proximity to ports like Qingdao and Tianjin reduces freight costs by 12–18% compared to inland competitors.

The industrial ecosystems enable rapid prototyping and scalable production, with most suppliers maintaining in-house foundries, CNC machining centers, and testing rigs within 5-kilometer radii. This integration supports lead times of 20–35 days for standard units and allows flexibility for OEM/ODM configurations. Buyers benefit from localized material access—particularly Q345 structural steel and wear-resistant manganese alloys—which lowers unit costs by 15–25% versus offshore alternatives. Monthly output capacity across verified suppliers ranges from 30 to 200 sets, accommodating both small-scale distributors and bulk infrastructure contractors.

How to Choose Mini Concrete Block Making Machine Suppliers?

Effective supplier selection requires structured evaluation across technical, operational, and transactional dimensions:

Technical Compliance

Confirm adherence to ISO 9001 quality management standards as a baseline. For markets in Europe, North America, or GCC countries, CE marking is essential for regulatory clearance. Validate performance claims through documented testing of compaction pressure (typically 10–18 MPa), cycle time (15–30 seconds per mold), and dimensional accuracy (±1mm tolerance). Request certification for electrical components (e.g., Siemens or ABB motors) and hydraulic systems (ISO 4406 cleanliness levels).

Production Capability Audits

Assess infrastructure maturity using these benchmarks:

- Minimum factory area of 3,000m² for stable batch production

- In-house design teams capable of mold customization (block types: solid, hollow, interlocking, paver)

- Integrated CNC fabrication and welding lines to ensure frame rigidity

Cross-reference on-time delivery rates (target ≥98%) and response times (ideally ≤4 hours) with order volume history to gauge reliability.

Transaction Safeguards

Utilize secure payment mechanisms such as third-party escrow until post-arrival inspection. Prioritize suppliers with transparent transaction records, including verifiable reorder rates and resolved dispute histories. Conduct sample testing against ASTM C90 or EN 771-3 standards to evaluate block density (≥1,800 kg/m³), compressive strength (≥7.5 MPa), and water absorption (<10%).

What Are the Best Mini Concrete Block Making Machine Suppliers?

| Company Name | Location | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|---|

| Hebei Zhongke Jiantong Machinery Equipment Co., Ltd. | Hebei, CN | Brick Making Machinery, Concrete Mixers, Wood Crushers | $289–4,100 | 1 set | 100% | ≤4h | <15% | US $80,000+ |

| Henan Xinkaitai Machinery Manufacturing Co., Ltd. | Henan, CN | Brick Making Machinery | $399–1,250 | 1 set | 100% | ≤4h | Not available | Not available |

| Qingdao HF Machinery Technology Co., LTD | Shandong, CN | Customizable Block Machines, Hydraulic Molds | $2,700–31,500 | 1 set | 100% | ≤5h | 28% | US $130,000+ |

| SUMU (Shanghai) Automation Engineering Co., Ltd. | Shanghai, CN | Brick Making Machinery, Concrete Mixers | $1,000–180,000 | 1 set | 100% | ≤2h | 20% | US $10,000+ |

| ZHENGZHOU SPOM MINING MACHINERY LLC | Henan, CN | Crusher, Brick Making Machinery, Concrete Mixers | $400 | 1 set | Not available | ≤3h | Not available | Not available |

Performance Analysis

Hebei Zhongke Jiantong and Henan Xinkaitai offer competitive entry-level models under $500, ideal for startups or regional distributors. Qingdao HF stands out for mid-to-high-end automation, with full hydraulic systems priced above $12,000 and strong customization support for mold design and color coding. SUMU demonstrates engineering versatility, offering both manual mini units and turnkey plants exceeding $150,000. ZHENGZHOU SPOM provides standardized low-cost options at $400/set but lacks verifiable performance metrics. Suppliers with reorder rates above 20%—notably Qingdao HF and SUMU—demonstrate consistent product satisfaction. Prioritize partners with documented after-sales service networks, especially for installation guidance and spare parts availability.

FAQs

How to verify mini concrete block making machine supplier reliability?

Cross-check ISO/CE certifications with accredited bodies. Request facility videos showing CNC machining, welding processes, and load testing. Analyze customer reviews focusing on uptime, ease of operation, and technical support responsiveness. Verify export experience via shipment records or bill of lading data.

What is the average lead time for custom machines?

Standard models ship within 20–25 days. Customized configurations—including voltage adjustments (110V/220V/380V), mold designs (interlocking, paver, hollow), or automation upgrades—require 30–45 days depending on complexity.

Can suppliers accommodate low MOQs for trial orders?

Yes, all listed suppliers accept single-set orders. This allows buyers to conduct field testing before scaling procurement. Some offer discounted samples if converted into full orders.

Do manufacturers support global shipping and customs clearance?

Established suppliers manage international logistics via FOB, CIF, or DAP terms. Confirm compliance with destination regulations, particularly for electrical safety (e.g., UL listing in the U.S.). Sea freight is optimal for containers carrying 10+ units, reducing per-unit shipping costs by up to 40%.

What customization options are commonly available?

Suppliers typically support modifications in block size (4", 6", 8"), mold type (solid, hollow, decorative), power source (electric/diesel), and control panel language. Advanced options include PLC automation, vibratory table integration, and color dosing systems for pigmented blocks.