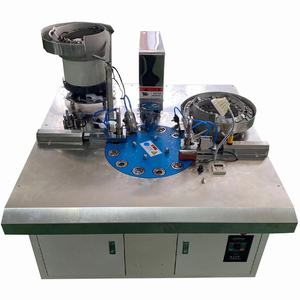

Mr Button Machine

About mr button machine

Where to Find Mr Button Machine Suppliers?

China remains the central hub for button machine manufacturing, with key suppliers concentrated in Zhejiang, Tianjin, and Guangdong provinces. These regions host vertically integrated production ecosystems that support rapid prototyping, high-volume output, and flexible customization. Zhejiang and Guangdong are particularly notable for advanced machining infrastructure and proximity to port logistics, enabling efficient export operations. Suppliers in these clusters benefit from localized access to precision tooling, pneumatic components, and CNC fabrication services, reducing material lead times by 20–30% compared to non-specialized regions.

The industrial networks in these zones allow for scalable production models—from small-batch semi-automatic units to fully automated pressing systems. Buyers gain access to mature supply chains where raw materials, heat treatment, mold design, and final assembly are managed within tightly coordinated geographic radii. This integration supports average delivery cycles of 15–30 days for standard configurations and facilitates cost advantages, with production efficiencies translating to 15–25% lower unit pricing than equivalent Western-built machinery.

How to Choose Mr Button Machine Suppliers?

Selecting a reliable supplier requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

Confirm the supplier's engineering capacity to produce machines compatible with multiple button types (snap, magnetic, badge, or thread-based). Look for documented experience in die-cutting, electric tapping (M6–M30), and interchangeable pneumatic heads. For custom applications, verify availability of end-mill grinding, drill bit sharpening, and lathe tool processing—capabilities highlighted in top-tier suppliers' service portfolios.

Production Infrastructure Assessment

Evaluate critical operational metrics:

- Minimum factory area exceeding 3,000m² for stable batch production

- In-house R&D or customization teams capable of modifying stroke force, mold size (e.g., 50x50mm, 80x80mm), and power source (electric/pneumatic)

- Proven track record in producing both manual and semi-automatic systems

Cross-reference declared capabilities with on-time delivery performance (target ≥93%) and response time (ideally ≤3 hours) as indicators of operational reliability.

Quality and Transaction Assurance

Prioritize suppliers offering third-party quality validation or compliance documentation. While formal certifications like ISO 9001 are not universally declared in this segment, consistent reorder rates (>15%) and 100% on-time delivery records serve as proxy indicators of process discipline. Utilize secure payment mechanisms and request pre-shipment inspection rights. Conduct sample testing to evaluate pressing consistency, mold alignment accuracy, and motor durability under continuous load.

What Are the Best Mr Button Machine Suppliers?

| Company Name | Location | Online Revenue | On-Time Delivery | Reorder Rate | Avg. Response | Customization Options | Min. Order Quantity | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Zhejiang Meiri Intelligent Machinery Co., Ltd. | Zhejiang, CN | US $220,000+ | 100% | 20% | ≤3h | Yes | 1–10 sets | $165–$680 |

| Talent (Tianjin) Electronics Co., Ltd. | Tianjin, CN | US $330,000+ | 96% | <15% | ≤10h | Yes | 1 set | $67.50–$795 |

| Yancheng Stik Pro Machinery Equipment Co., Ltd. | Jiangsu, CN | US $120,000+ | 100% | 17% | ≤3h | Limited | 1 set | $60–$3,949 |

| Guangzhou Junyu Sewing Equipment Co., Ltd. | Guangdong, CN | US $100,000+ | 93% | 17% | ≤3h | Limited | 10 sets | $20–$3,500 |

| MARS EXIM PRIVATE LIMITED | India | US $200+ | 33% | - | ≤6h | No | 1–1000 pcs | $1.20–$95.62 |

Performance Analysis

Zhejiang Meiri stands out with full customization capabilities, 100% on-time delivery, and competitive pricing across electric tapping and grinding models. Talent (Tianjin) leads in revenue volume and offers broad configurability in size, shape, and magnet integration, though its reorder rate suggests room for improvement in customer retention. Yancheng Stik Pro and Guangzhou Junyu demonstrate strong responsiveness and punctuality, making them reliable for urgent procurement, while Guangzhou Junyu’s $20–30 range presents an entry-level option for budget-conscious buyers. MARS EXIM, based in India, offers ultra-low per-unit pricing but exhibits significantly lower delivery reliability (33%), indicating higher fulfillment risk.

FAQs

How to verify Mr button machine supplier reliability?

Assess on-time delivery history, response time consistency, and online transaction volume. Request evidence of past client engagements or facility operations. For high-value orders, conduct video audits of production lines and validate component sourcing practices.

What is the typical MOQ and lead time?

Standard MOQ ranges from 1 set (for premium models) to 10 sets for economy batches. Semi-automatic and pneumatic systems may require 100–1,000 pieces. Lead times typically span 10–20 days post-payment, depending on customization level and stock availability.

Can suppliers customize button machine specifications?

Yes, leading manufacturers offer modifications in diameter (M6–M30), voltage (110V/220V), pressing force, and mold compatibility. Custom graphic labeling, logo engraving, and multi-size interchangeability are available through suppliers like Zhejiang Meiri and Talent (Tianjin).

Do suppliers provide samples?

Sample availability varies. Some suppliers include test units with bulk orders, while others charge partial fees recoverable upon full purchase. Expect 5–10 days for sample production and 3–7 days for international express delivery.

What are common machine types and applications?

Available models include electric tapping machines (MR-DS24, MR-DS30), universal head pressers (MR-DS36), and pneumatic badge makers. Applications span garment accessories, promotional items, industrial fasteners, and DIY crafting. Select based on required cycle speed, material thickness, and die-change frequency.