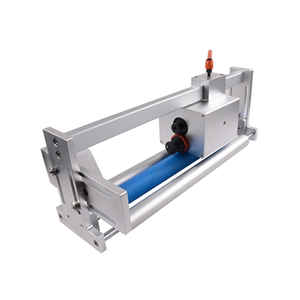

Multipurpose Batch Coding And Mrp Printing Machine

About multipurpose batch coding and mrp printing machine

Where to Find Multipurpose Batch Coding and MRP Printing Machine Suppliers?

China remains the central hub for manufacturing multipurpose batch coding and MRP printing machines, with key industrial clusters concentrated in Anhui, Guangdong, and Hubei provinces. These regions host vertically integrated production ecosystems that combine precision engineering, inkjet subsystem assembly, and automated control systems under one supply chain. Anhui-based suppliers, such as those in Hefei, leverage proximity to semiconductor and electronics manufacturing zones to source high-reliability print heads and embedded controllers, reducing component lead times by up to 30%. Guangdong’s machinery corridor, centered on Guangzhou, benefits from mature packaging automation expertise and export-oriented logistics infrastructure, enabling faster order processing for international buyers.

The clustering effect supports scalable production across multiple printer types—including handheld TIJ (thermal inkjet), continuous inkjet (CIJ), and thermal transfer overprinters (TTO)—with shared access to calibration labs, consumables formulation, and firmware development. This integration allows suppliers to offer competitive pricing, with standard handheld models starting below $100 and industrial-grade online coders ranging from $700–$1,500. Average monthly output capacity among mid-tier suppliers exceeds 500 units, facilitating both small-batch procurement and volume contracts. Localization of ink chemistry R&D further enhances performance adaptability, particularly for challenging substrates like frozen film, glass, or metalized pouches.

How to Choose Multipurpose Batch Coding and MRP Printing Machine Suppliers?

Procurement decisions should be guided by technical validation, operational reliability, and post-purchase support readiness:

Technical Compliance & System Integration

Confirm compatibility with required coding standards: date/lot/MRP/expiry serialization, multi-line text, logos, barcodes (1D/2D), and variable data input via PLC or PC interface. For regulated industries (pharmaceuticals, food), ensure printers support audit trails, user-access controls, and GMP-compliant design. While explicit ISO 9001 certification is not listed in available data, prioritize suppliers demonstrating structured quality processes through consistent delivery performance and traceable component sourcing.

Production Capability Verification

Assess supplier infrastructure using proxy indicators:

- On-time delivery rate exceeding 95% (verified via transactional data)

- Demonstrated customization capability (e.g., font size adjustment, dual-head configuration, multilingual support)

- In-house control software development and firmware update protocols

Cross-reference product range breadth—especially presence of industrial CIJ/TTO systems—with declared online revenue (target >US$90,000/year) to gauge scale and market validation.

Transaction Risk Mitigation

Utilize secure payment mechanisms that align financial release with physical verification at destination. Evaluate response time (target ≤4 hours) and reorder rate (>15%) as proxies for customer satisfaction and service responsiveness. Request sample prints or video demonstrations validating print resolution (minimum 300 dpi), adhesion on target materials, and resistance to smudging under specified conditions (e.g., low temperature, moisture).

What Are the Best Multipurpose Batch Coding and MRP Printing Machine Suppliers?

| Company Name | Location | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Price Range (USD) | Customization Options | Product Range |

|---|---|---|---|---|---|---|---|---|

| Hefei Qimei Packing Machinery Co., Ltd. | Anhui, CN | US $210,000+ | 99% | ≤2h | 20% | $30–299 | Yes | Multipurpose handheld, mini, industrial multi-head |

| Smartcode Printing Technologies LLC | Guangdong, CN | Not disclosed | Not disclosed | ≤3h | Not disclosed | $600–6,500 | Limited | TTO, envelope coder, Markem-compatible systems |

| Guangzhou Dafeng Machinery Co., Ltd. | Guangdong, CN | US $90,000+ | 92% | ≤4h | 18% | $350–1,499 | Yes | Handheld, portable jet, online pouch coder |

| Wuhan Amark Technology Co., Ltd. | Hubei, CN | US $20,000+ | 91% | ≤4h | <15% | $24–624 | Yes | Handjet color, automatic expiry, serial number |

| Hefei Hanjie Packing Machinery Ink-Jet Printer Co., Ltd. | Anhui, CN | US $150,000+ | 98% | ≤3h | 17% | $29–340 | Yes | Desktop, handheld mini, high-definition portable |

Performance Analysis

Hefei Qimei leads in operational consistency with a 99% on-time delivery rate and strong customization support across a broad price spectrum. Smartcode targets specialized industrial applications with high-end TTO systems priced above $2,000, indicating focus on durability and integration rather than entry-level demand. Guangzhou Dafeng offers mid-range industrial solutions with proven export activity and reliable fulfillment metrics. Wuhan Amark provides cost-competitive options but exhibits lower reorder propensity, suggesting room for improvement in long-term customer retention. Hefei Hanjie combines high responsiveness (≤3h) with diversified output, including multi-language and high-resolution models suitable for complex labeling tasks. Buyers seeking scalability should prioritize suppliers with documented customization workflows and firmware flexibility.

FAQs

What are typical MOQ and lead times for batch coding machines?

Minimum Order Quantity (MOQ) is typically 1 unit across all major suppliers, accommodating prototyping and pilot deployment. Standard lead time ranges from 7–15 days for in-stock configurations. Custom firmware, special ink formulations, or dual-head setups may extend production to 25 days. Air freight adds 5–10 days for global delivery.

Can these machines print on non-porous and frozen surfaces?

Yes, provided fast-drying, solvent-based inks are used. Several suppliers explicitly reference performance under frozen conditions and on glass, plastic, and laminated films. Verify ink compatibility with substrate chemistry and environmental exposure (e.g., refrigeration, transport humidity).

Do suppliers offer free samples or testing units?

Sample policies vary. Some suppliers provide printed samples at no cost, while functional unit trials may require partial payment refundable against future orders. Expect sampling fees covering 30–50% of unit cost for high-value models (>$1,000).

Are software and connectivity features standardized?

Basic models support USB and RS232 interfaces with simple PC-based editing. Advanced units include Wi-Fi, Ethernet, or PLC synchronization for line integration. Confirm supported file formats, character sets (including Cyrillic, Asian languages), and ability to import CSV data for batch variation management.

How to assess print quality and durability before purchase?

Request test videos showing real-time coding on your target material. Evaluate edge definition, character height (typically 1.5–12.7mm), and resistance to abrasion or moisture after 24-hour cure. Where possible, conduct side-by-side comparisons using identical substrates and environmental conditions.