Namkeen Machine Price In India

Top sponsor listing

Top sponsor listing

CN

CN

CN

CN

About namkeen machine price in india

Where to Find Namkeen Machine Suppliers?

Global supply of namkeen making machines is primarily concentrated in China and India, with Indian manufacturers increasingly emerging as cost-competitive sources for domestic and regional markets. Key production hubs are located in Gujarat, Uttar Pradesh, and Maharashtra—regions with established food processing equipment ecosystems supported by skilled metal fabrication workshops and electrical component suppliers. These clusters enable integrated manufacturing of extrusion systems, dough feeding mechanisms, and frying conveyors essential for automated snack production.

Suppliers leverage localized supply chains to maintain competitive pricing, with standard semi-automatic models priced between $200–$600 per unit. The proximity of raw material vendors (stainless steel, motors, heating elements) reduces lead times to 15–30 days for small-batch orders. Modular designs allow configuration flexibility for regional snack varieties such as sev, chakli, and murukku, supporting both cottage-scale operations and expanding commercial producers.

How to Choose Namkeen Machine Suppliers?

Evaluating suppliers requires a structured assessment across technical, operational, and transactional parameters:

Technical Specifications & Customization

Confirm machine compatibility with target product profiles: diameter range (3–12mm), output capacity (5–50kg/hour), and power requirements (single-phase vs. three-phase). Verify availability of customizable molds, variable speed control, and oil filtration integration. Suppliers like LEENOVA KITCHEN EQUIPMENTS PRIVATE LIMITED offer adjustable motor speeds and shape-specific dies, enabling multi-product use on a single platform.

Production and Quality Assurance

Prioritize suppliers demonstrating consistent build quality and process control. While formal certifications (ISO, CE) are infrequently listed in available data, assess indirect indicators:

- On-time delivery rates ≥97%

- Response time ≤6 hours

- Online transaction volume exceeding US $500,000 annually

- In-house R&D or engineering support for mold design

Cross-reference product listings with material specifications—food-grade stainless steel (SS304 preferred) and IP-rated electrical components indicate adherence to hygiene and safety standards.

Transaction Reliability

Favor suppliers with verifiable performance metrics. Jiaozuo Taoding Trading Co., Ltd. reports a 97% on-time delivery rate and an online revenue track record above US $550,000, suggesting scalable operations. Reorder rates below 15% across multiple suppliers may reflect limited customer retention or niche market positioning. Utilize secure payment terms and request pre-shipment inspection rights to mitigate risk.

What Are the Best Namkeen Machine Suppliers?

| Company Name | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Revenue Indicator |

|---|---|---|---|---|---|---|---|

| Jiaozuo Taoding Trading Co., Ltd. | Grain Product Making Machines, Dough Mixer, Snack Machines | Not specified | Varies | 97% | ≤2h | <15% | US $550,000+ |

| LEENOVA KITCHEN EQUIPMENTS PRIVATE LIMITED | Namkeen Making Machine, Besan Mixer, Food Processing Equipment | $310–590 | 1 piece | Not reported | ≤6h | Not reported | Not reported |

| PLATINA OVERSEAS | Namkin Machine, Masala Grinder, Vegetable Cutter | $200–250 | 1 piece | Not reported | ≤7h | Not reported | Not reported |

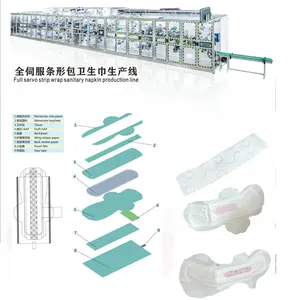

| Quanzhou Rainbow Machinery Co., Ltd. | Paper Product Making Machinery | $7,000–20,000 | 1 set | 100% | ≤5h | Not reported | Not reported |

| Xuchang Xinjiuzhou Intelligent Equipment Co., Ltd. | Paper Napkin Making Machines | $10,999–19,545 | 1 set | 100% | ≤7h | <15% | Not reported |

Performance Analysis

Jiaozuo Taoding stands out with documented reliability (97% on-time delivery) and strong digital sales performance, indicating robust back-end operations. LEENOVA and PLATINA offer entry-level pricing ideal for startups or low-volume producers, though transparency on fulfillment history is limited. Notably, Quanzhou Rainbow and Xuchang Xinjiuzhou report 100% on-time delivery, but their product focus appears misaligned—offering napkin-making machinery rather than food processing equipment. Buyers must verify whether “namkeen machine” listings are accurate or keyword-misaligned entries targeting unrelated paper goods.

FAQs

How to verify namkeen machine supplier reliability?

Request evidence of past transactions, facility photos, and client references. Validate machine specifications against sample videos or third-party inspection reports. Use escrow-based payment systems to ensure delivery compliance. Scrutinize discrepancies between listed products and core business lines—e.g., cookware or paper machinery suppliers listing namkeen equipment may lack domain expertise.

What is the typical MOQ and lead time?

Minimum order quantities typically start at 1 unit for individual buyers and SMEs. Lead times range from 10–25 days depending on customization level and supplier location. Domestic Indian suppliers may deliver faster (within 10–14 days) compared to cross-border shipments from China, which require 20–35 days including customs clearance.

Can namkeen machines be customized?

Yes, many suppliers offer mold variations for different shapes (spiral, straight, coiled), adjustable thickness settings, and voltage configurations. Some provide options for logo imprinting, color coding, and extended conveyor belts. Confirm customization lead time and tooling costs before finalizing orders.

Do suppliers provide after-sales support?

Support varies significantly. Leading suppliers may offer basic troubleshooting guides or video tutorials. For technical maintenance, buyers should clarify warranty terms (typically 6–12 months), spare parts availability, and accessibility of service technicians—especially critical for motor and heating element failures.

Are there risks in sourcing low-priced namkeen machines?

Sub-$300 units may use inferior materials (non-food-grade metals, underpowered motors) leading to shorter lifespan and contamination risks. Conduct material verification and consider lifecycle cost over initial price. Low-cost models often lack overload protection or temperature controls, increasing operational hazards in continuous-use environments.