Namkeen Maker Machine Price

About namkeen maker machine price

Where to Find Namkeen Maker Machine Suppliers?

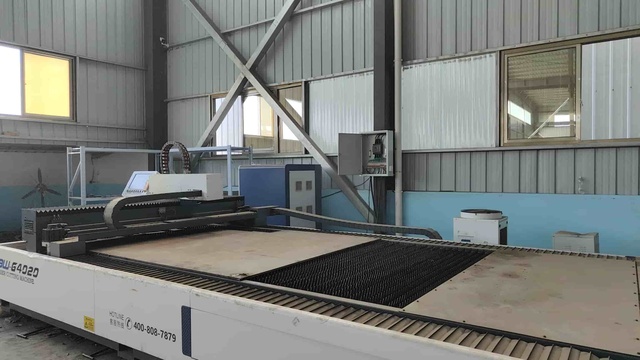

China and India represent the core manufacturing hubs for namkeen maker machines, with concentrated industrial activity in Henan and Shandong provinces (China) and Gujarat (India). Chinese suppliers, particularly in Zhengzhou and Jinan, specialize in fully automated production lines capable of extruding, shaping, frying, and packaging snack varieties such as Kurkure, Gathiya, and Bhujia. These clusters benefit from integrated steel and electrical component supply chains, enabling 20–30% lower production costs compared to standalone manufacturers in other regions.

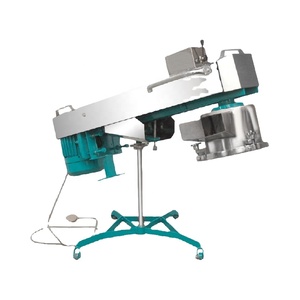

Indian suppliers, led by private enterprises in Ahmedabad and Mumbai, focus on compact, semi-automatic units tailored for small to mid-scale food processors. These machines emphasize ease of operation and maintenance, often constructed with food-grade stainless steel and modular dies for product diversification. The regional ecosystems support rapid prototyping and customization, with many suppliers offering turnkey solutions including training and after-sales service. Buyers gain access to scalable options—from entry-level units under $500 to high-capacity automated lines exceeding $30,000—supported by localized technical networks and streamlined export logistics.

How to Choose Namkeen Maker Machine Suppliers?

Procurement decisions should be guided by objective evaluation criteria to ensure performance, reliability, and compliance:

Technical Specifications & Production Capacity

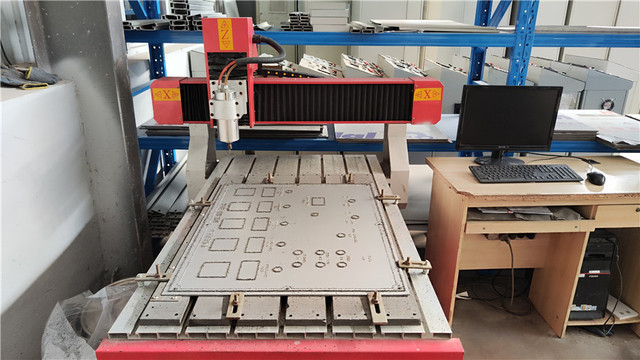

Assess machine throughput (kg/hour), automation level (manual, semi-auto, fully auto), and compatibility with target products (e.g., extruded snacks, dough sticks, coated namkeens). Verify construction materials—preferably SUS304 stainless steel for hygiene—and motor specifications (voltage, power rating). For commercial operations, demand minimum production capacity of 100 kg/hour and modular die sets for multi-product flexibility.

Quality Assurance & Compliance

Prioritize suppliers providing ISO 9001 certification or equivalent quality management systems. While CE marking is not universally present, it remains a critical benchmark for European and North American market compliance. Request documentation on material sourcing, welding standards, and electrical safety testing. Third-party inspection reports or factory audit videos enhance transparency, especially for remote procurement.

Supplier Performance Metrics

Evaluate based on verifiable operational data:

- On-time delivery rate ≥95%

- Reorder rate >30% indicating customer retention

- Average response time ≤4 hours

- Minimum 1 year of verified transaction history

Cross-reference these metrics with order volume trends and online revenue indicators where available to assess scalability and market trust.

What Are the Best Namkeen Maker Machine Suppliers?

| Company Name | Location | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|---|

| Zhengzhou Xinshijia Machinery Equipment Co., Ltd. | Henan, CN | Namkeen Making Machines, Grain Processing, Snack Lines | $1,285–1,985 | 1 set | 100% | ≤2h | <15% | $20,000+ |

| LEENOVA KITCHEN EQUIPMENTS PRIVATE LIMITED | Gujarat, IN | Namkeen Makers, Farsan Machines, Coating Pans | $310–1,030 | 1 piece | Not specified | ≤6h | Not specified | Not specified |

| Jinan Sunward Machinery Co., Ltd. | Shandong, CN | Fully Automatic Namkeen Machines, Kurkure Lines | $5,000–29,800 | 1 set | 96% | ≤3h | 45% | $880,000+ |

| Jinan Shengrun Machinery Co., Ltd. | Shandong, CN | Kurkure, Nik-Naks, Indomie Noodle Lines | $19,999–35,000 | 1 set | 100% | ≤4h | Not specified | $80,000+ |

| Nanchang Kay Xin Yue Technologies Co., Ltd. | Jiangxi, CN | Compact Noodle & Pasta Makers, Small-Scale Snack Units | $119–288 | 1 piece | 75% | ≤8h | 15% | $50,000+ |

Performance Analysis

Jinan Sunward stands out with the highest reorder rate (45%) and substantial online revenue ($880,000+), indicating strong market acceptance and repeat business—key indicators of product reliability and post-sale support. Zhengzhou Xinshijia and Jinan Shengrun report 100% on-time delivery, reflecting robust production planning and logistics execution. LEENOVA offers the most competitive entry-level pricing (from $310), suitable for startups or businesses testing new snack lines. However, limited performance data necessitates additional due diligence. Nanchang Kay Xin Yue provides ultra-low-cost units but shows lower delivery reliability (75%), posing potential risk for time-sensitive deployments.

FAQs

What is the typical MOQ and lead time for namkeen maker machines?

Standard minimum order quantity is 1 set or unit. Lead times range from 15–30 days for standard configurations, extending to 45 days for customized automation lines. Expedited production may be available upon request, depending on supplier capacity.

Can suppliers customize namkeen making machines?

Yes, select manufacturers offer customization in color, material grade, logo branding, and output capacity. Fully automatic lines can be engineered for specific snack profiles (e.g., spiral, square, triangle) using interchangeable dies. Confirm design capabilities through technical drawings or video demonstrations prior to order placement.

Do namkeen maker machines comply with international food safety standards?

Compliance varies by manufacturer. Reputable suppliers use food-grade stainless steel (SUS304) and adhere to hygienic design principles. While formal certifications like CE or NSF are not universal, buyers should request material test reports and electrical safety documentation to verify adherence to local regulations.

Are spare parts and technical support available post-purchase?

Most established suppliers provide basic spare parts packages and remote troubleshooting via video or manual guidance. Some offer on-site technician deployment or training at an additional cost. Clarify support terms—including language availability and response windows—before finalizing contracts.

How are namkeen maker machines packaged and shipped internationally?

Machines are typically crated in seaworthy wooden cases with moisture protection. Shipping options include FOB, CIF, or DDP terms depending on supplier policy. Sea freight is standard for full sets due to size and weight; air freight is viable only for compact models. Confirm incoterms, insurance coverage, and import duties applicable in the destination country.