Fully Automatic Namkeen Making Machine Price

CN

CN

CN

CN

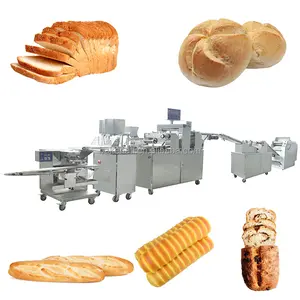

About fully automatic namkeen making machine price

Where to Find Fully Automatic Namkeen Making Machine Suppliers?

China remains the dominant manufacturing hub for fully automatic namkeen making machines, with key supplier clusters concentrated in Shandong and Henan provinces. These regions host specialized food processing equipment manufacturers that leverage vertically integrated supply chains and advanced fabrication capabilities. Jinan (Shandong) is home to multiple OEMs producing extrusion-based snack machinery, while Zhengzhou (Henan) serves as a logistics and production nexus for industrial-scale food processing lines, enabling cost efficiencies of 20–35% compared to equivalent European or Indian suppliers.

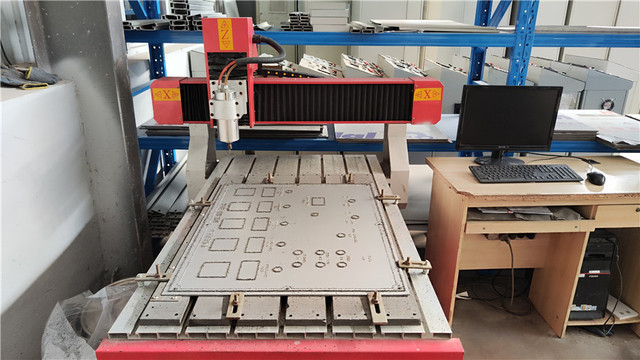

The regional ecosystems support rapid prototyping and scalable production, with many suppliers operating facilities exceeding 5,000m² and maintaining in-house R&D teams focused on automation and energy efficiency. Buyers benefit from localized access to CNC machining, stainless steel fabrication, and control system integration, reducing component lead times. Average production cycles range from 20–45 days for standard configurations, with modular designs allowing adaptation for diverse snack types including Kurkure, Cheetos, Nik-Nik, and sev.

How to Choose Fully Automatic Namkeen Making Machine Suppliers?

Procurement decisions should be guided by rigorous technical and operational assessments:

Technical Compliance & Certification

Verify adherence to ISO 9001 standards for quality management systems. For export to regulated markets, confirm CE marking and compliance with IEC electrical safety standards. Request documentation on motor ratings, PLC control units (e.g., Siemens or Delta), and material contact certification (food-grade stainless steel AISI 304/316).

Production Capability Assessment

Evaluate supplier infrastructure using these benchmarks:

- Minimum factory area of 3,000m² to ensure batch production capacity

- In-house engineering team for customization (e.g., shape dies, output tuning)

- Integrated testing line for dry-run validation prior to shipment

Cross-reference claimed capabilities with verified performance metrics such as on-time delivery rates (>95%) and reorder frequency.

Transaction Security & Quality Assurance

Utilize secure payment mechanisms like escrow services until post-delivery inspection is completed. Prioritize suppliers offering sample testing—functional prototypes can validate output consistency, oil consumption, and product shaping accuracy. Demand video audits of assembly processes and final calibration tests before dispatch.

What Are the Best Fully Automatic Namkeen Making Machine Suppliers?

| Company Name | Location | Verified Supplier Type | Main Products | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Jinan Sunward Machinery Co., Ltd. | Jinan, Shandong, CN | Custom Manufacturer | Namkeen, Fried Snack, Food Processing Lines | 96% | ≤3h | 45% | US $890,000+ | $7,000–$40,000 |

| Zhengzhou Kingdoo Machinery Co., Ltd. | Zhengzhou, Henan, CN | - | Grain Product Machines, Packaging Lines | 100% | ≤3h | 100% | US $410,000+ | $75,000–$120,000 |

| Jinan Mingde Machinery Co., Ltd. | Jinan, Shandong, CN | - | Pet Food, Snack, Bean Processing Machines | - | ≤2h | 100% | - | $7,500–$15,000 |

| Zhengzhou Qiongdan Machinery Co., Ltd. | Zhengzhou, Henan, CN | - | Other Snack, Grain, Meat Machines | 100% | ≤2h | <15% | US $10,000+ | $900–$10,000 |

| FENG LIAN DA MACHINERY CO LTD | - | - | Snack, Feed, Pet Food Machines | - | ≤1h | - | - | $3,000–$59,000 |

Performance Analysis

Zhengzhou Kingdoo stands out for high-end production lines, targeting large-scale operations with price points above $75,000 and a perfect on-time delivery and reorder record. Jinan Sunward offers broad customization options—including color, logo, and packaging labeling—with proven export volume and mid-range pricing. Jinan Mingde demonstrates strong customer retention (100% reorder rate) and fast response times despite limited public delivery data. FENG LIAN DA provides the widest price spectrum, accommodating both entry-level ($3,000) and mid-tier automated systems. Buyers seeking compact or niche formats (e.g., naan or pancake variants) may consider Zhengzhou Qiongdan, though its low reorder rate suggests limited scalability or after-sales support depth.

FAQs

What is the typical MOQ and lead time for namkeen making machines?

Minimum Order Quantity is typically 1 set across all major suppliers. Lead times vary: standard models ship within 20–30 days, while customized configurations require 35–50 days depending on complexity and component availability.

Can suppliers customize machine specifications?

Yes, most suppliers offer full customization including output capacity (50–500 kg/h), die shapes (spiral, slanty, tube), control panel language, voltage (380V/50Hz or custom), and branding elements. Custom tooling development usually takes 7–14 days post-approval.

Do manufacturers provide installation and training support?

Support varies by supplier. Leading exporters include remote troubleshooting and basic operation manuals. Some offer on-site technician deployment at additional cost (typically $150–$250/day plus travel). Confirm service terms during contract negotiation.

Are there differences in machine construction materials?

Yes. Premium models use AISI 304 stainless steel for all food-contact surfaces, while budget versions may incorporate carbon steel with anti-rust coating. Ensure material specifications are documented to meet food safety regulations in the destination market.

How to compare pricing versus value?

Beyond initial cost, assess total value through energy efficiency (kW/h per kg output), automation level (PLC vs relay control), spare parts availability, and warranty coverage (typically 12 months). Machines priced below $5,000 may lack critical safety interlocks or durable extrusion screws, increasing long-term TCO.