Automatic Namkeen Making Machine Price

Top sponsor listing

Top sponsor listing

CN

CN

About automatic namkeen making machine price

Where to Find Automatic Namkeen Making Machine Suppliers?

China remains the dominant hub for automatic snack processing machinery, with key manufacturing clusters in Henan and Shandong provinces driving innovation and cost efficiency in the production of namkeen making machines. These regions host vertically integrated supply chains that encompass extrusion systems, forming molds, frying or baking modules, and packaging integration—critical for fully automated lines. Henan’s Zhengzhou and Jinan in Shandong have emerged as centers for food-grade engineering, supported by localized access to stainless steel, PLC control units, and servo motor suppliers.

The industrial ecosystem enables rapid prototyping and scalable production, with many manufacturers operating end-to-end facilities capable of delivering turnkey solutions. Buyers benefit from consolidated logistics networks reducing component lead times by 20–30% compared to offshore alternatives. Average delivery cycles range from 25–40 days for standard configurations, while customization adds 7–15 days depending on complexity. The concentration of technical expertise allows for competitive pricing structures across entry-level semi-automatic units and high-capacity fully automated systems.

How to Choose Automatic Namkeen Making Machine Suppliers?

Selecting a reliable supplier requires due diligence across technical, operational, and transactional dimensions:

Technical Compliance & Safety Standards

Verify adherence to ISO 9001 for quality management systems. For export markets, CE certification is essential to meet European safety directives for electrical and mechanical components. Confirm use of food-grade materials (e.g., SUS304 stainless steel) in contact zones and compliance with hygiene standards such as HACCP design principles. Request documentation on motor insulation class, thermal overload protection, and oil filtration system specifications where applicable.

Production Capability Assessment

Evaluate core manufacturing indicators:

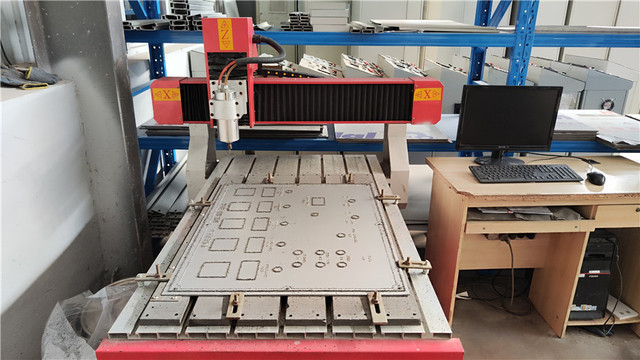

- Minimum factory area exceeding 3,000m² to support assembly lines and testing bays

- In-house mold design and fabrication capability for custom shape, size, and thickness configurations

- Integration of variable frequency drives (VFD) for belt speed control and energy-efficient operation

Cross-reference claimed output capacity (kg/h or pieces/h) with verified customer references and on-time delivery performance (target ≥96%).

Customization & After-Sales Support

Prioritize suppliers offering comprehensive customization: product shape (sticks, curls, squares), thickness (1–8mm), color (via seasoning drum integration), and packaging interface compatibility. Confirm availability of remote diagnostics, multilingual manuals, and spare parts inventory. Video-based factory audits can validate R&D investment and process control protocols before order placement.

What Are the Best Automatic Namkeen Making Machine Suppliers?

| Company Name | Main Products | Online Revenue | On-Time Delivery | Response Time | Reorder Rate | Customization Options | Product Range (Price Range) |

|---|---|---|---|---|---|---|---|

| Jinan Sunward Machinery Co., Ltd. | Other Snack Machines, Grain Product Making Machines | US $960,000+ | 96% | ≤3h | 43% | Color, material, size, logo, packaging, label, graphic, capacity | $5,000–$37,000 |

| Henan Gondor Industry Co., Ltd. | Other Snack Machines, Grain Product Making Machines | US $530,000+ | 100% | ≤2h | 21% | Color, material, size, logo, packaging, label, graphic | $549–$11,999 |

| Jiaozuo Dingchang Machinery Equipment Co., Ltd. | Grain Product Making Machines, Other Snack Machines | US $130,000+ | 100% | ≤2h | <15% | Belt speed, motor, mold size/shape/thickness, noise level, packaging, rows, capacity, yield, automation level, diameter, material, cooling, logo, graphic | Multiproduct listing (no direct pricing) |

| Jinan FLD Machinery CO.,LTD | Snack Extrusion Lines, Kurkure/Cheetos Production Systems | US $70,000+ | 100% | ≤1h | 16% | Color, material, shape, size, drawing, logo, packaging, label, graphic, capacity | $8,000–$12,000 |

| Zhengzhou Xinshijia Machinery Equipment Co., Ltd. | Other Snack Machines, Noodle Processing Equipment | US $20,000+ | 100% | ≤2h | <15% | Limited explicit mention; focuses on main product categories | $850–$1,985 |

Performance Analysis

Jinan Sunward stands out with the highest reported online revenue and robust reorder rate (43%), indicating strong market acceptance and repeat business—suggestive of effective after-sales service and consistent machine reliability. Henan Gondor offers the most accessible price point starting below $600, positioning it competitively for small-scale producers, though its mid-range reorder rate suggests room for improvement in long-term client retention. Jiaozuo Dingchang provides extensive customization depth, particularly in automation parameters and mold engineering, ideal for buyers requiring precise output specifications. Jinan FLD excels in responsiveness (≤1h response time) and targets mid-tier commercial operations with standardized Cheetos- and Kurkure-style production lines. Zhengzhou Xinshijia presents budget-friendly options but has limited transparency on customization scope, which may constrain scalability for specialized applications.

FAQs

What is the typical MOQ and pricing structure for automatic namkeen making machines?

Most suppliers list a minimum order quantity (MOQ) of 1 set, enabling pilot procurement and performance evaluation. Entry-level models start at $549 for basic configurations, while fully automated high-capacity lines reach up to $37,000. Pricing correlates directly with output capacity, degree of automation, and material build quality.

How long does it take to fulfill an order?

Standard orders are typically fulfilled within 25–35 days after deposit confirmation. Customized systems involving unique mold designs or integrated seasoning/frying sections may extend lead times to 40–50 days. Expedited builds are available upon negotiation, subject to production line availability.

Can suppliers provide machine validation samples?

Yes, reputable manufacturers offer sample production runs using buyer-specified dough formulations. Samples are produced on actual production lines and shipped within 10–14 days post-approval of technical parameters. Sample fees are often credited toward full equipment orders.

Do these machines support international voltage and frequency standards?

Most suppliers engineer machines for dual-voltage compatibility (380V/50Hz or 220V/60Hz) and can configure control panels for single-phase or three-phase inputs. Confirm electrical specs during inquiry to ensure seamless integration into local infrastructure.

What logistical support do suppliers offer?

Established exporters provide FOB terms with coordination for sea or air freight. Full container loads (FCL) are recommended for cost efficiency, especially when bundling multiple units. Some suppliers partner with freight forwarders to manage customs clearance documentation for major markets including India, Southeast Asia, Africa, and South America.