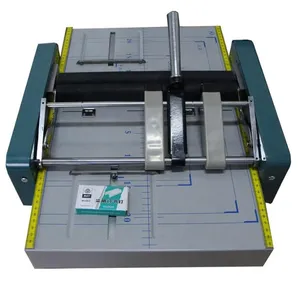

Notebook Making Machine Wholesale

Top sponsor listing

Top sponsor listing

CN

CN

CN

CN

About notebook making machine wholesale

Where to Find Notebook Making Machine Suppliers?

China remains the global hub for notebook making machine manufacturing, with key industrial clusters concentrated in Henan, Zhejiang, and Guangdong provinces. These regions host vertically integrated supply chains that combine paper processing, binding technology, and post-press automation under one ecosystem. Zhengzhou in Henan Province is emerging as a center for heavy-duty paper product machinery, supported by regional logistics advantages and proximity to raw material suppliers. Hangzhou and Shenzhen serve as innovation and export gateways, offering advanced electromechanical integration and faster response times for international buyers.

The clustering effect enables suppliers to offer competitive pricing due to localized component sourcing—reducing production costs by 20–30% compared to non-specialized manufacturers. Facilities typically integrate design, fabrication, assembly, and testing, allowing lead times as short as 15–30 days for standard models. Buyers benefit from scalable output, with some suppliers reporting monthly production capacities exceeding 100 units across multiple machine types, including spiral binders, wire comb systems, and fully automated cover laminators.

How to Choose Notebook Making Machine Suppliers?

Selecting reliable partners requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

Confirm suppliers possess core competencies in paper processing and binding automation. Key indicators include in-house development of control systems (e.g., PLC or servo-driven mechanisms), experience with folding, stitching, cutting, and edge-gluing processes, and compatibility with diverse materials such as kraft paper, synthetic covers, and thermal adhesives. Prioritize companies listing “Paper Processing Machinery,” “Binding Machines,” or “Post-Press Equipment” among their main products.

Production Infrastructure Assessment

Evaluate the following benchmarks:

- Facility size supporting batch production (minimum 2,000m² recommended)

- In-house R&D or engineering teams capable of customization

- Integration of CNC machining, welding, and electrical assembly lines

Cross-reference declared capabilities with on-time delivery performance (target ≥95%) and reorder rates (ideally >25%) to validate reliability.

Quality & Transaction Assurance

While formal certifications like ISO 9001 are not universally listed, prioritize suppliers demonstrating consistent quality through verifiable metrics: 100% on-time delivery, sub-3-hour response times, and documented after-sales support. Use secure payment methods with inspection clauses before final disbursement. Request machine test videos or remote facility walkthroughs to verify claims about automation level and build quality.

What Are the Best Notebook Making Machine Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization | Min. Order Flexibility |

|---|---|---|---|---|---|---|---|---|

| Zhengzhou Zomagtc Co., Ltd. | Henan, CN | Paper Processing Machinery, Binding Machines | US $1,400,000+ | 100% | ≤2h | 41% | Yes (material, size, logo, packaging) | Mixed product lines, high volume |

| Tech Gold Technology Co., Ltd. | Guangdong, CN | Post-Press Equipment, Fully Automatic Machines | US $5,000+ | 100% | ≤2h | <15% | Limited data, likely OEM-focused | 1 set minimum, high-unit-cost machines |

| Shenzhen Hongyuan Stationery Co., Ltd. | Guangdong, CN | Notebook Spiral Machines, Desktop Binders | US $20,000+ | 100% | ≤2h | <15% | Yes (color, material, logo, packaging) | 1 set minimum, mid-range pricing |

| Hangzhou Seven Office Supplies Co., Ltd. | Zhejiang, CN | Binding Machines, Laminators | US $20,000+ | 89% | ≤3h | 25% | Manual/electric comb binders available | As low as 1 piece for certain models |

| YUHE PRINT COMPANY LIMITED | Unknown, CN | Notebooks, Gift Sets, School Supplies | Data Unavailable | Not Reported | ≤5h | Not Reported | Focus on finished notebooks, not machinery | Low MOQs (100–500 pcs) for consumables |

Performance Analysis

Zhengzhou Zomagtc stands out with the highest reported online revenue and a 41% reorder rate, indicating strong customer retention and scalability. Its specialization in paper processing and binding equipment aligns closely with industrial-grade notebook production needs. Tech Gold Technology offers high-end automated solutions—including leather cover edge machines and book sewing systems—though lower reorder rates suggest potential gaps in service or niche targeting.

Shenzhen Hongyuan provides balanced value with responsive communication, full customization options, and accessible entry points at 1-set MOQs. Hangzhou Seven excels in small-scale binding equipment suitable for office or light commercial use, with unusually flexible ordering (as low as 1 piece). YUHE PRINT appears focused on finished goods rather than machinery, making it less relevant for capital equipment procurement.

FAQs

How to verify notebook making machine supplier reliability?

Assess on-time delivery records (target ≥95%), average response time (ideal ≤3 hours), and evidence of repeat business (reorder rate >25%). Request video demonstrations of machine operation and inquire about after-sales technical support availability. Verify whether the supplier is a manufacturer or reseller—custom manufacturers offer greater flexibility.

What is the typical MOQ and lead time?

For complete machines, MOQ is typically 1 set, especially for semi-automatic or fully automatic models. Lead times range from 15 to 30 days depending on complexity. Customizations may extend delivery by 7–14 days. For spare parts or accessories, bulk orders (e.g., 500–1,000 units) may apply.

Do suppliers support customization?

Yes, many suppliers offer customization in material compatibility, machine size, voltage specifications (110V/220V), control interfaces, and branding (logo, color scheme). High-end manufacturers can adapt folding width, binding type (spiral, comb, wire-o), and integration with feeding or stacking systems.

Can these machines handle different notebook formats?

Most modern machines support A4, A5, and custom sizes. Adjustable guides and modular tooling allow switching between softcover, hardcover, stitched, or glued bindings. Confirm format compatibility and changeover time with the supplier before purchase.

What are the shipping and installation considerations?

Machines are typically shipped FOB with wooden crate packaging. Sea freight is cost-effective for full-container loads; air freight suits urgent single-unit deliveries. Installation usually requires basic technical oversight—some suppliers provide setup manuals or remote guidance. For complex systems, confirm if on-site technician deployment is available (may incur additional fees).