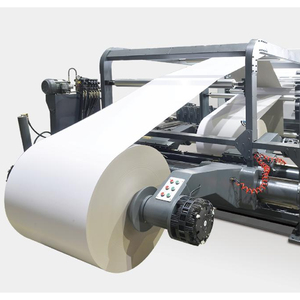

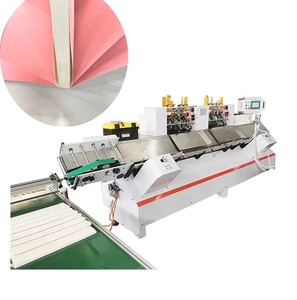

Notebook Making Machine

Top sponsor listing

Top sponsor listing

CN

CN

About notebook making machine

Where to Find Notebook Making Machine Suppliers?

China remains the global epicenter for notebook making machine manufacturing, with key industrial hubs concentrated in Henan and Shandong provinces. These regions host vertically integrated supply chains that streamline production from raw material sourcing to final assembly. Zhengzhou, the capital of Henan, serves as a major logistics and machinery production hub, offering efficient domestic and international distribution networks. Shandong’s coastal cities, including Qingdao, provide proximity to deep-water ports, reducing export lead times by 10–15% compared to inland competitors.

The clustering effect enables suppliers to achieve economies of scale, with many operating facilities exceeding 5,000m² and maintaining in-house capabilities for CNC machining, welding, and automation integration. This infrastructure supports rapid prototyping and scalable production, allowing manufacturers to fulfill orders ranging from single units to full container loads within 30–45 days. Buyers benefit from localized component sourcing, which reduces machine production costs by 20–30% versus equivalent Western-built equipment, while maintaining compliance with international safety and performance standards.

How to Choose Notebook Making Machine Suppliers?

Selecting reliable suppliers requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Certifications

Verify adherence to ISO 9001 quality management systems as a baseline. For exports to Europe or North America, confirm CE marking and compliance with local electrical and mechanical safety regulations. Request documentation on motor efficiency, control system specifications (e.g., PLC brands), and material handling tolerances—critical for consistent output in high-volume environments.

Production Capability Assessment

Evaluate supplier infrastructure using these benchmarks:

- Facility size ≥3,000m² indicating capacity for batch production

- In-house engineering teams capable of customization (e.g., binding type, feeding mechanism, automation level)

- Integration of precision components such as servo motors, touch-screen HMI panels, and pneumatic systems

Cross-reference listed product ranges with actual machinery photos and video demonstrations to verify technical claims and assess build quality.

Transaction Reliability Indicators

Prioritize suppliers with verifiable performance metrics: on-time delivery rates ≥98%, response times ≤2 hours, and reorder rates above 30%. Analyze transaction volume where available—suppliers reporting annual online revenues exceeding US $100,000 demonstrate market validation and operational stability. Use secure payment mechanisms and request pre-shipment inspection rights to mitigate procurement risk.

What Are the Best Notebook Making Machine Suppliers?

| Company Name | Location | Main Products (Listings) | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Price Range (USD) | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Zhengzhou Zomagtc Co., Ltd. | Henan, CN | Paper Processing Machinery (1,455) | 100% | ≤2h | 41% | US $1,300,000+ | $4,800–$130,000 | Color, material, size, thickness, logo, packaging, graphic design |

| Qingdao YiDaFa International Trade Co., Ltd. | Shandong, CN | Paper Processing Machinery (N/A) | 100% | ≤2h | - | - | $150,000–$220,000 | Kraft paper, thickness, packaging, label, material size, conical nail binding, waste paper width |

| Zhengzhou Ximenger Machinery Co., Ltd. | Henan, CN | Paper Processing Machinery (855) | 100% | ≤2h | 41% | US $90,000+ | $1,750–$10,100 | Limited (based on listed models) |

| Henan Yingsheng Supply Chain Management Co., Ltd. | Henan, CN | Paper Processing Machinery (260) | 100% | ≤2h | <15% | US $40,000+ | $522–$5,099 | Binding type, hole punching, corner rounding, size |

Performance Analysis

Zhengzhou Zomagtc Co., Ltd. stands out with a broad product range, high transaction volume, and extensive customization capabilities, positioning it as a preferred partner for medium to large-scale buyers requiring tailored solutions. Qingdao YiDaFa targets high-end automated lines, with machines priced above $150,000, suggesting specialization in industrial-grade, high-speed production systems. Zhengzhou Ximenger offers competitively priced semi-automatic models suitable for small to mid-sized operations, backed by strong delivery reliability and repeat business indicators. Henan Yingsheng provides entry-level equipment at significantly lower price points, ideal for startups or niche producers, though its low reorder rate suggests room for improvement in long-term customer retention.

FAQs

How to verify notebook making machine supplier reliability?

Cross-check ISO or CE certifications with issuing bodies. Request factory audit reports or video walkthroughs to validate production processes. Assess responsiveness, order fulfillment history, and customer feedback focusing on after-sales service and technical support.

What is the average lead time for notebook making machines?

Standard models typically ship within 20–30 days after order confirmation. Customized or fully automatic systems may require 45–60 days depending on complexity. Air freight reduces delivery time to 5–10 days internationally, while sea freight averages 25–35 days.

Can suppliers accommodate customization requests?

Yes, most established suppliers offer customization in binding type (spiral, wire-o, saddle-stitch), material compatibility (paper weight, cover thickness), machine dimensions, and branding elements. High-end models may include PLC programming adjustments for feed speed, alignment precision, and output counting.

Do manufacturers provide samples or trial runs?

Some suppliers offer live demonstration videos or test production logs. Full machine samples are uncommon due to size and cost, but buyers can request sample booklets produced by the machine under specified parameters before placing bulk orders.

What are typical MOQ and payment terms?

Minimum order quantity is typically 1 set. Payment terms vary: 30% deposit with balance before shipment is standard. Escrow services or trade assurance programs are recommended to secure transactions, especially for first-time partnerships.