Open Source Form Builder

CN

CN

CN

CN

CN

CN

About open source form builder

Where to Find Open Source Form Builder Suppliers?

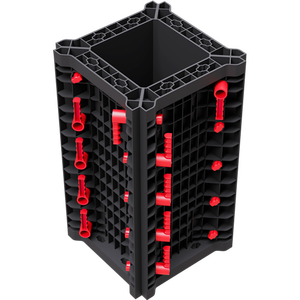

The term "open source form builder" in industrial sourcing contexts refers not to software, but to modular, reusable construction formwork systems designed for concrete casting—often marketed under digital keywords due to e-commerce tagging practices. Leading suppliers are concentrated in northern China, particularly in Tianjin, Shandong, and Shanxi provinces, where integrated metalworking and plastics manufacturing ecosystems support high-volume production of steel, aluminum, and plastic formwork panels.

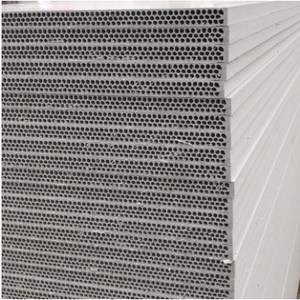

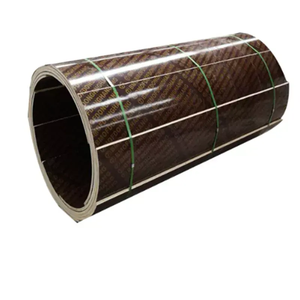

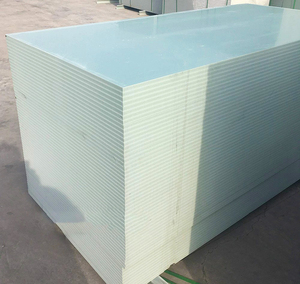

Tianjin and Shandong specialize in heavy-duty steel and aluminum alloy systems, leveraging proximity to raw material sources and deep-industrial port infrastructure for cost-efficient export logistics. Shanxi has emerged as a hub for innovative plastic-based formwork, utilizing polypropylene (PP) and PVC composites that offer lightweight handling and corrosion resistance. These clusters enable vertically integrated production—from mold design and extrusion to surface treatment and assembly—reducing component lead times by 20–30% compared to decentralized supply models.

Suppliers in these regions typically operate multi-material production lines, supporting both traditional site-assembled systems and prefabricated modular units. Average monthly output capacity ranges from 10,000 to 50,000 square meters per facility, with standard lead times of 25–40 days for bulk orders. The regional concentration also facilitates rapid prototyping and customization, particularly for large-scale infrastructure or prefab housing projects.

How to Choose Open Source Form Builder Suppliers?

Selecting reliable suppliers requires verification across technical, operational, and transactional dimensions:

Material & Design Compliance

Confirm the use of standardized engineering materials: Q235/Q345 steel for load-bearing frames, 6061-T6 aluminum alloys for reusable wall systems, and high-density polypropylene (HD-PP) for plastic variants. Demand structural load calculations and deflection test reports, especially for tall wall or column formwork. CE marking is common among exporters, though third-party validation of mechanical performance per EN 12812 or ACI 347 standards is recommended for critical applications.

Production Infrastructure Assessment

Evaluate key operational indicators:

- Minimum factory area of 3,000m² to ensure stable output

- In-house capabilities in CNC cutting, automated welding, and anodizing/powder coating (for aluminum)

- Plastic formwork producers should have twin-screw extrusion lines and UV-stabilized compound blending

- Cross-reference online revenue data and reorder rates as proxies for market acceptance and fulfillment reliability

Customization & Transaction Security

Most suppliers offer dimensional, color, and branding customization (e.g., logo embossing, panel labeling). Prioritize partners advertising ≤3-hour response times and 100% on-time delivery records. Use secure payment mechanisms such as escrow or letter of credit for initial orders. Request physical samples to assess edge durability, connection rigidity, and surface finish before scaling procurement.

What Are the Best Open Source Form Builder Suppliers?

| Company Name | Location | Main Materials | Min. Order (MOQ) | Price Range (USD) | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|---|

| Tianjin Taishouxing International Co., Ltd. | Tianjin, CN | Steel, Galvanized Metal | 200–1000 units | $25.99–50 | 100% | ≤1h | 33% | $2.8M+ |

| Shandong Boyoun Heavy Industries Co., Ltd. | Shandong, CN | Steel, Structural Alloy | 40–100 tons | $1,000–1,499 | 100% | ≤9h | Not available | Not available |

| Shanxi Sufeng New Material Technology Co., Ltd. | Shanxi, CN | PVC, PP Plastic | 1 meter – 150 m² | $1.50–13.20 | 100% | ≤2h | <15% | $30K+ |

| MTM BUILDING MATERIALS CO.,LTD | Fujian, CN | PP Plastic, Aluminum | 100 pieces | $19 | 100% | ≤3h | 44% | $1.5M+ |

| Work-Sun (beijing) International Trade Co., Ltd. | Beijing, CN | Aluminum Alloy, Plastic | 2–200 m² | $8.50–110 | 100% | ≤1h | 16% | $20K+ |

Performance Analysis

Tianjin Taishouxing and MTM Building Materials demonstrate strong commercial traction, supported by high online revenues and repeat order volumes, indicating robust quality control and customer service. MTM stands out with a 44% reorder rate at a competitive fixed price point ($19), suggesting consistent product satisfaction in the mid-tier segment. Shandong Boyoun targets large infrastructure projects with tonnage-based pricing, ideal for bridge and pier construction requiring high-load capacity formwork. Shanxi Sufeng offers the lowest entry-level pricing for plastic systems, suitable for budget-sensitive or short-cycle builds. Work-Sun provides premium aluminum solutions with rapid response times, catering to buyers needing fast iteration on custom designs.

FAQs

What does "open source form builder" mean in construction sourcing?

In industrial procurement, this term refers to modular, interoperable formwork systems—typically made from steel, aluminum, or plastic—that allow open adaptation and reconfiguration on-site. It is often used in digital marketplaces as a keyword for reusable, customizable concrete molds rather than software platforms.

What are typical MOQs and pricing structures?

MOQs vary by material: plastic systems start as low as 1 meter or 50 pieces ($1.50–$13.20), while steel and aluminum systems require 200+ square meters or tonnage commitments ($25–$1,500 per unit). Fixed pricing is common for standardized plastic panels; steel systems often quote per ton or project scope.

How long do production and shipping take?

Standard production lead time is 25–40 days after sample approval. Sea freight adds 15–30 days depending on destination. Air shipping is viable only for small samples due to weight and volume constraints.

Can suppliers provide custom-sized or branded formwork?

Yes, most suppliers listed offer size, color, and logo customization. Minimum thresholds apply—typically 500+ units for branding. Engineering modifications (e.g., interlocking mechanisms, lifting points) require technical drawings and may involve tooling fees.

What certifications should I verify?

Look for ISO 9001 for quality management. For exports, CE marking is frequently cited, though independent testing to EN 12812 (formwork loads) or ASTM C31 (concrete curing) provides stronger assurance. Request mill test certificates for metal components and UV resistance reports for plastic variants.