Open Source Typeform

CN

CN

CN

CN

About open source typeform

Where to Find Open Source Typeform Suppliers?

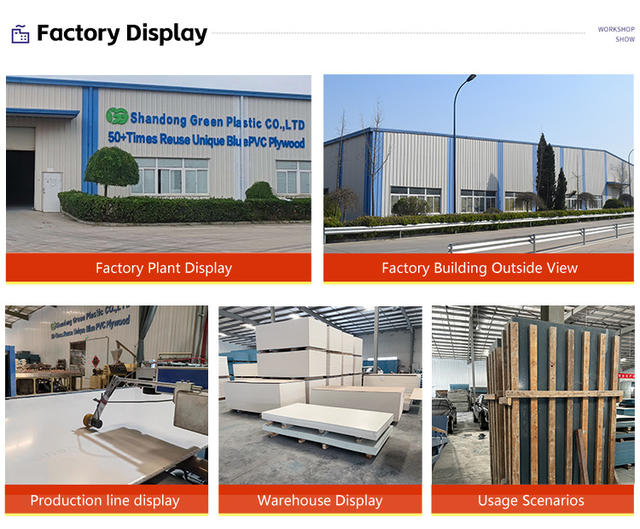

The global supply base for formwork systems marketed under "open source typeform" identifiers is concentrated in China’s Shandong, Henan, and Shanxi provinces. These regions host specialized manufacturers of plastic and steel-based reusable formwork, leveraging localized polymer processing and metal fabrication clusters. Shandong and Henan dominate production volume, supported by integrated logistics networks and proximity to raw material suppliers—particularly PVC and ABS resins—reducing input costs by 15–25% compared to offshore alternatives.

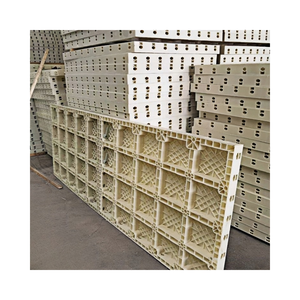

Industrial zones in Zhengzhou (Henan) and Qingdao (Shandong) feature vertically aligned supply chains, where injection molding, extrusion lines, and galvanization facilities operate within close geographic proximity. This integration enables rapid prototyping and scalable production runs, with standard lead times averaging 20–35 days for containerized orders. Buyers benefit from modular design frameworks that support interoperability across systems—an operational parallel to software-based open-source principles—facilitating hybrid configurations in concrete construction projects.

How to Choose Open Source Typeform Suppliers?

Procurement decisions should be guided by structured evaluation criteria focused on technical capability, compliance, and transaction reliability:

Material & Design Specifications

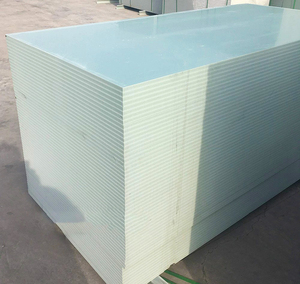

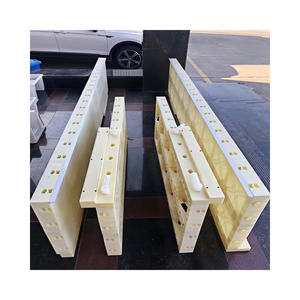

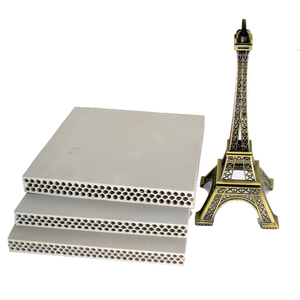

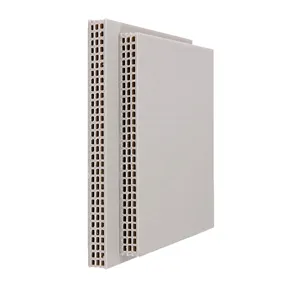

Confirm base material composition: PVC, PP, or ABS plastics must meet ASTM D4216 or EN 12872 standards for structural performance. For steel formwork, verify Q235 or equivalent tensile strength grades. Request product drawings and load-bearing test reports to validate wall thickness, interlocking mechanism integrity, and deflection resistance under wet concrete pressure (typically 50–75 kN/m²).

Production Infrastructure Assessment

Prioritize suppliers with documented manufacturing capacity:

- Minimum 3,000m² factory area for consistent batch output

- In-house mold design and CNC tooling capabilities

- Monthly production capacity exceeding 50,000 square meters or 10,000 units

Cross-reference facility size claims with online revenue metrics and order fulfillment history to assess scalability.

Quality & Transaction Assurance

While formal certifications (ISO 9001, CE) are not universally declared in available data, prioritize suppliers reporting 100% on-time delivery and response times ≤2 hours. Utilize third-party trade assurance programs to secure payments until post-delivery inspection. Request physical or digital samples to evaluate surface finish, dimensional accuracy, and ease of assembly before scaling procurement.

What Are the Best Open Source Typeform Suppliers?

| Company Name | Location | Main Materials | Customization Options | Min. Order Quantity | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Zhengzhou Songmao Building Materials Co., Ltd. | Henan, CN | ABS, Plastic, Steel | Color, thickness, size, bracing, layout, waterproofing | 1–2 pieces / 100 m² | 100.0% | ≤2h | US $1.4M+ | 22% |

| MTM BUILDING MATERIALS CO.,LTD | Shandong, CN | Plastic | Color, material, logo, packaging, graphic | 100 pieces | 100.0% | ≤3h | US $1.5M+ | 50% |

| Linyi Consmos New Building Materials Co., Ltd. | Shandong, CN | Steel, Q235 | Adjustable height, width, column length, skirting | 100–300 pieces | 100.0% | ≤3h | US $460K+ | 50% |

| Shanxi Sufeng New Material Technology Co., Ltd. | Shanxi, CN | PVC | Color, size, logo, packaging, graphic | 1 meter | 100.0% | ≤2h | US $80K+ | <15% |

| Qingdao Ambition Plastic Industry Co., Ltd. | Shandong, CN | PP, Hollow Plastic | Color, size, thickness | 1 square meter | 100.0% | ≤2h | US $120K+ | <15% |

Performance Analysis

MTM Building Materials and Linyi Consmos exhibit high customer retention (50% reorder rate), indicating strong satisfaction with product consistency and technical adaptability. Zhengzhou Songmao stands out for low MOQ flexibility and extensive customization depth, supporting pilot deployments and niche applications. Shandong-based suppliers dominate in per-unit scalability and material diversity, while Shanxi and Henan firms offer competitive pricing starting at $1.50/meter for PVC variants. All listed suppliers report perfect on-time delivery records, though response speed varies—prioritize those with sub-2-hour engagement for time-sensitive project coordination.

FAQs

What materials are used in open source typeform systems?

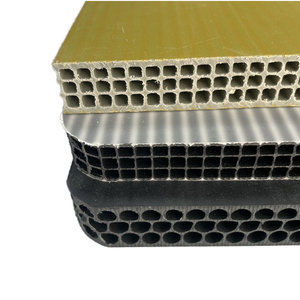

Primary materials include recyclable PVC, PP, and ABS plastics for lightweight, corrosion-resistant panels. Steel formwork typically uses Q235-grade carbon steel with galvanized or zinc-coated finishes for durability in high-cycle pours. Hybrid systems combine plastic edges with metal reinforcement for structural stability.

What is the typical minimum order quantity?

MOQs range from 1 meter (PVC sheets) to 100–300 pieces (plastic/steel panels). Some suppliers offer sample orders at reduced quantities. Bulk pricing applies consistently above 100 m² or 1,000 units, with unit costs decreasing up to 30% at scale.

Can these formwork systems be customized?

Yes, most suppliers support customization in dimensions, color coding, branding (logo imprinting), interlocking patterns, and accessories like bracing or handles. Technical modifications such as adjustable height mechanisms or waterproof coatings require engineering validation prior to production.

What are the average lead times for shipment?

Standard production and packing cycles take 15–25 days after order confirmation. Sea freight adds 20–40 days depending on destination port. Air shipping is viable for samples (7–10 days globally) but cost-prohibitive for full-scale orders.

Are there quality certifications to verify?

While ISO 9001 and CE marks are not explicitly stated in supplier profiles, buyers should request internal quality control documentation, including material test reports, dimensional inspection sheets, and load simulation data. Third-party lab verification is recommended for critical infrastructure projects.