Pallets For Block Machine Producer

1/28

1/28

CN

CN

1/16

1/16

1/30

1/30

1/27

1/27

1/18

1/18

CN

CN

CN

CN

1/29

1/29

1/16

1/16

About pallets for block machine producer

Where to Find Pallets for Block Machine Producer Suppliers?

China leads global production of industrial pallets designed for block machine systems, with key manufacturing clusters in Shandong and Henan provinces. These regions host vertically integrated facilities specializing in both wooden and composite material handling platforms. Qingdao, in particular, has emerged as a hub for GMT (glass mat thermoplastic) and PVC-based pallet manufacturing, leveraging local polymer supply chains and advanced molding technologies. Shandong’s proximity to major ports enables efficient export logistics, reducing transit times by up to 15% compared to inland regions.

The industrial ecosystem supports diverse material streams—wood, plastic, and fiber-reinforced composites—enabling suppliers to serve automated concrete block lines, brick-making plants, and modular construction units. Production integration allows rapid scaling from prototype to mass output, with standard lead times ranging from 20–40 days depending on material complexity and order volume. Buyers benefit from localized component sourcing, including hydraulic pressing systems, nailing machines, and CNC notching equipment, all available within 50km radius supplier networks.

How to Choose Pallets for Block Machine Producer Suppliers?

Effective supplier selection requires structured evaluation across technical, operational, and transactional dimensions:

Material & Design Compliance

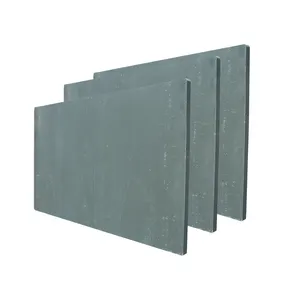

Confirm compatibility between pallet specifications and block machine automation requirements. Key parameters include dimensional tolerance (±2mm), load-bearing capacity (typically 2–5 tons), and surface flatness for consistent mold release. For high-cycle operations, prioritize reinforced GMT or steel-framed wooden pallets rated for over 10,000 uses. Demand test reports validating resistance to moisture, thermal stress, and chemical exposure, especially for outdoor curing environments.

Production Capacity Verification

Assess infrastructure readiness through objective indicators:

- Minimum factory area exceeding 3,000m² for continuous production

- In-house molding, pressing, and assembly lines to ensure process control

- Demonstrated monthly output capacity above 1,000 units

Cross-reference online revenue data and reorder rates to validate market demand and operational stability.

Quality Assurance & Transaction Security

Prioritize suppliers with documented quality management practices. While formal ISO certification is not universally present, evidence of systematic inspection protocols—such as pre-shipment testing and batch traceability—is critical. Utilize secure payment mechanisms where possible, and request product samples before committing to bulk orders. Evaluate response time and communication clarity as proxies for post-sale support effectiveness.

What Are the Best Pallets for Block Machine Producer Suppliers?

| Company Name | Location | Main Products | Price Range (Unit/Min. Order) | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Customization |

|---|---|---|---|---|---|---|---|---|

| Qingdao Saifan Packaging Machinery Manufacturing Co., Ltd. | Shandong, CN | Wood Pallet Production Lines, Automatic Nailing Machines | $6,900–335,000; Min. 1–10 sets | 100% | ≤2h | - | - | Limited |

| Qingdao Midwell Industry And Trade Co., Ltd. | Shandong, CN | GMT Plastic Pallets, Double-Faced Industrial Platforms | $10; Min. 100 pieces | 100% | ≤2h | <15% | US $20,000+ | Yes |

| Zhengzhou Thoyu Mechanical & Electrical Equipment Co., Ltd. | Henan, CN | Wood Pallet Block Making Machines, Euro-Block Systems | $7,000–33,000; Min. 1 set | - | ≤12h | 50% | US $10,000+ | Limited |

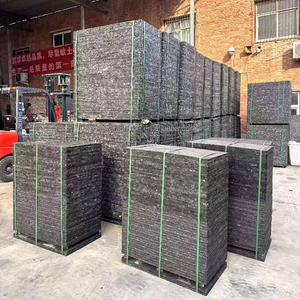

| Shandong Brick Machinery Co., Ltd. | Shandong, CN | GMT Block Pallets, Cement Brick Handling Platforms | $3.50–3.90; Min. 10–100 pieces | 100% | ≤1h | 33% | US $140,000+ | Yes |

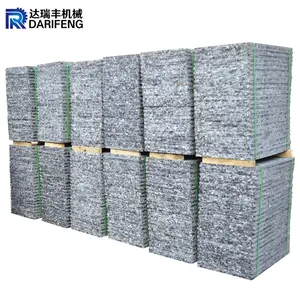

| Qingdao Darifeng Machinery Co., Ltd. | Shandong, CN | PVC/GMT Pallets, Bamboo Composite Platforms | $2–10; Min. 2–100 pieces | 97% | ≤5h | 50% | US $510,000+ | Extensive (size, material, logo, packaging) |

Performance Analysis

Qingdao-based suppliers dominate in delivery reliability, with three companies reporting 100% on-time performance. Shandong Brick Machinery Co., Ltd. stands out for competitive pricing ($3.50/unit at MOQ 100), making it suitable for cost-sensitive procurement. Qingdao Darifeng offers the broadest customization scope, supporting tailored thickness, color, weight, and branding options—critical for OEM integration. Zhengzhou Thoyu demonstrates strong customer retention (50% reorder rate), indicating satisfaction with machine durability and after-sales service despite slower response times. Buyers seeking full production lines should consider Saifan’s high-capacity automated systems, while those needing consumable pallets may prefer Midwell’s standardized GMT models.

FAQs

What materials are used in block machine pallets?

Common materials include wood (for traditional nailing systems), GMT (glass mat thermoplastic) for corrosion resistance, PVC for lightweight handling, and bamboo-composite hybrids. Steel-reinforced variants are used in high-load applications.

What is the typical MOQ for industrial pallets?

MOQ varies by material and supplier: wooden pallets often require 1–10 sets of machinery, while plastic/GMT pallets are sold in batches of 100 pieces. Some suppliers offer sample orders starting at 2–10 units.

How long does production and shipping take?

Manufacturing lead time ranges from 20–40 days post-deposit. Sea freight to international destinations adds 25–40 days depending on region. Air shipping is viable for samples (7–10 days).

Can suppliers customize pallet dimensions and load ratings?

Yes, many suppliers offer dimensional adjustments, thickness variation, and reinforcement options. Verified customization capabilities include hydraulic pressure tuning, mold design, and logo imprinting.

Are there industry certifications for block machine pallets?

No universal certification exists, but buyers should verify structural testing data and material compliance (e.g., RoHS for plastics). For integrated machinery lines, CE marking on associated equipment indicates adherence to safety standards.