Paper Box Machine Maker

Top sponsor listing

Top sponsor listing

About paper box machine maker

Where to Find Paper Box Machine Suppliers?

China remains the global epicenter for paper box machine manufacturing, with key production hubs in Henan, Zhejiang, and Guangdong provinces. These regions host vertically integrated industrial clusters specializing in packaging machinery, supported by mature supply chains for raw materials like corrugated board, food-grade paper, and adhesive systems. Zhengzhou in Henan and Wenzhou in Zhejiang are particularly notable for high-density concentrations of OEMs producing automated forming, die-cutting, and gluing equipment.

The clustering effect enables streamlined access to component suppliers, CNC fabrication workshops, and logistics networks—reducing lead times and production costs. Facilities within these zones typically operate under lean manufacturing principles, offering buyers scalable solutions from semi-automatic benchtop models to fully automated production lines capable of 200–500 boxes per minute. Average delivery windows range from 15–45 days depending on customization level, with localized sourcing cutting material procurement time by up to 30% compared to offshore alternatives.

How to Choose Paper Box Machine Suppliers?

Selecting a reliable supplier requires systematic evaluation across technical, operational, and transactional dimensions:

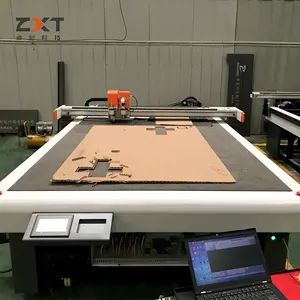

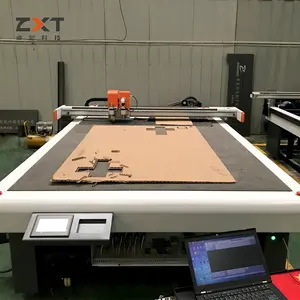

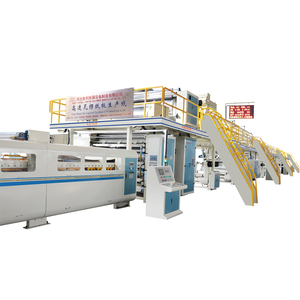

Technical & Production Capability

Assess whether suppliers maintain in-house engineering teams and control over core processes such as mechanical design, electrical integration, and software programming. Prioritize companies offering ISO-certified production environments (e.g., ISO 9001) and compliance with CE standards for electrical safety and machine operation. Verify that critical components—servo motors, PLCs, pneumatic systems—are sourced from reputable brands (Siemens, Mitsubishi, SMC).

Facility and Output Capacity

Key indicators include:

- Factory area exceeding 3,000m² to support assembly and testing of large-scale machines

- Monthly output capacity of at least 20–30 units for standard configurations

- In-house R&D departments enabling customization of folding patterns, sealing mechanisms, and feeding systems

Cross-reference declared capabilities with verified performance metrics such as on-time delivery rates (>95%) and reorder frequency.

Customization and Quality Assurance

Leading suppliers offer modular designs adaptable to various box types—pizza containers, takeaway lunch boxes, luxury gift packaging—with adjustable parameters for size, material thickness (120–600gsm), and printing compatibility. Confirm availability of pre-shipment inspection protocols, including load testing, noise measurement, and dimensional accuracy checks. Request sample production runs to validate consistency before full-scale orders.

What Are the Best Paper Box Machine Suppliers?

| Company Name | Location | Main Products (Listings) | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|---|

| ZHENGZHOU ALLRAISE COMPANY LTD. | Henan, CN | Paper Processing Machinery (1,563) | 96% | ≤3h | 40% | US $980,000+ | Color, material, size, logo, packaging, label, graphic |

| Ruian Xuanhai Machine Co., Ltd. | Zhejiang, CN | Paper Box Machines | 100% | ≤2h | 40% | US $30,000+ | Color, material, size, logo, packaging, label, graphic |

| Wenzhou Roman Machinery Co., Ltd. | Zhejiang, CN | Paper Slotting & Forming Machines | 100% | ≤2h | <15% | US $1,300,000+ | Color, material, size, logo, packaging, label, graphic |

| Foshan Sanniu Packaging Machinery Co., Ltd. | Guangdong, CN | Corrugated Box Making Machinery (86) | 100% | ≤8h | - | - | Not specified |

| Cangzhou Lighten Import & Export Trading Co., Ltd. | Hebei, CN | Corrugated Carton Production Lines | 100% | ≤3h | 75% | US $120,000+ | Die cutting, color, material, size, length, logo, packaging, label, graphic |

Performance Analysis

Cangzhou Lighten stands out with a 75% reorder rate—indicating strong customer satisfaction—and offers advanced customization for corrugated board processing. Despite lower online revenue, Ruian Xuanhai and Wenzhou Roman demonstrate perfect on-time delivery records and rapid response times, positioning them well for urgent procurement cycles. ZHENGZHOU ALLRAISE leads in product breadth with over 1,500 listings in paper processing machinery, suggesting extensive production scale and market reach. Foshan Sanniu focuses on high-end refurbished and multi-ply corrugated lines, though limited digital transparency may require additional due diligence. Buyers seeking automation for food packaging should prioritize suppliers with experience in sanitary-grade stainless steel construction and CE-marked controls.

FAQs

How to verify paper box machine supplier reliability?

Validate certifications through official registries and request factory audit reports or video walkthroughs. Analyze shipment history, focusing on consistent on-time delivery and post-sale service responsiveness. Third-party inspection services can verify machine functionality prior to dispatch.

What is the typical MOQ and pricing range?

Minimum order quantity is generally 1 set, with prices ranging from $430 for manual slotting units to over $400,000 for fully automated, multi-layer corrugated production lines. Used or refurbished systems offer cost savings of 30–50% but require thorough condition assessments.

Do suppliers support customization?

Yes, most leading suppliers provide tailored solutions for box dimensions, material type, branding elements, and automation level. Advanced options include integrated vision systems for defect detection and IoT-enabled monitoring for predictive maintenance.

What are standard lead times?

Lead times vary from 15 days for simple models to 60 days for complex, custom-engineered systems. Pre-shipment testing typically adds 5–7 days. Air freight reduces delivery time to 5–10 days globally, while sea freight remains economical for full-container loads.

Can suppliers handle international shipping and customs clearance?

Established exporters manage FOB, CIF, and DDP shipping terms and prepare documentation compliant with destination regulations. Confirm inclusion of packing lists, certificates of origin, and CE/ISO compliance files to avoid import delays.