Pcb Smt Assembly Process

CN

CN

Top sponsor listing

Top sponsor listing

1/24

1/24

1/2

1/2

CN

CN

1/15

1/15

1/51

1/51

1/44

1/44

About pcb smt assembly process

Where to Find PCB SMT Assembly Process Suppliers?

China remains the global epicenter for PCB SMT assembly manufacturing, with Shenzhen and Dongguan serving as core hubs due to their dense electronics ecosystems. These regions host vertically integrated facilities that combine PCB fabrication, surface mount technology (SMT), and through-hole (DIP) assembly under one roof, enabling end-to-end production from bare board to fully assembled PCBA. The concentration of component distributors, engineering talent, and logistics networks within the Pearl River Delta allows suppliers to achieve rapid turnaround times—typically 5–10 days for small-batch orders and 12–18 days for mass production.

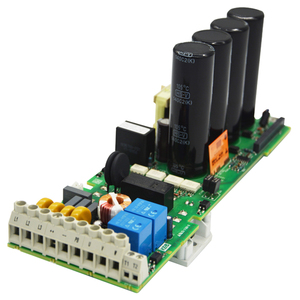

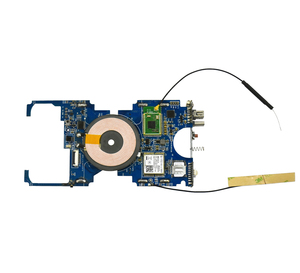

Suppliers in this region specialize in multi-layer rigid, flexible (FPC), and rigid-flex PCBs using FR4, high-frequency (e.g., Rogers), and metal-core substrates. Standard processing includes automated optical inspection (AOI), X-ray testing, reflow soldering, and selective wave soldering. Buyers benefit from scalable operations capable of handling prototyping runs (MOQ: 1 piece) to high-volume contracts (monthly output exceeding 500,000 units). Cost efficiency is further enhanced by localized sourcing of components and in-house design support for Gerber file optimization, BOM validation, and reverse engineering services.

How to Choose PCB SMT Assembly Process Suppliers?

Selecting a reliable partner requires rigorous evaluation across technical, operational, and transactional dimensions:

Quality & Compliance Verification

Confirm adherence to IPC-A-610 Class 2 or Class 3 standards for electronic assemblies. While explicit ISO 9001 certification is not always declared, prioritize suppliers demonstrating structured quality management systems via on-time delivery rates ≥97% and documented testing procedures (e.g., AOI, functional testing). For export to regulated markets, ensure compatibility with RoHS, REACH, and UL material requirements.

Production Capacity Assessment

Evaluate key indicators of scalability and process control:

- On-time delivery performance (target: ≥97%)

- Response time ≤2 hours for technical inquiries

- Support for mixed-technology assembly (SMT + DIP + plug-in)

- In-house capabilities in PCB design, component sourcing, and firmware programming

Cross-reference product listings with customization tags such as impedance control, ENIG/immersion silver finishes, and complex layer stackups (up to 32 layers).

Procurement Risk Mitigation

Utilize incremental engagement strategies: start with prototype orders to validate yield accuracy and documentation quality. Require sample submissions with full test reports before scaling. For high-value contracts, verify supplier stability through online revenue benchmarks (e.g., >US $200,000/year) and reorder rate trends. Engage only after confirming clear terms for intellectual property protection, especially when sharing Gerber files or BOMs.

What Are the Best PCB SMT Assembly Process Suppliers?

| Company Name | Main Products | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate | Customization Support | Verified Specialty |

|---|---|---|---|---|---|---|---|

| Toptek Pcb Co., Limited | PCBA, Multilayer PCB, FPC, Rigid-Flex, High Frequency | 100% | ≤1h | US $1,000+ | 66% | Limited | Multispecialty Supplier |

| Dongguan Zhiyi Kefeng Electronics Co., Ltd. | PCBA, Other Electronic Modules, ICs, Encoders | 100% | ≤2h | Not specified | - | Standard OEM | N/A |

| King Field Electronic Co., Ltd. (Shenzhen) | PCBA, PCB Design, Component Sourcing, Reverse Engineering | 93% | ≤2h | US $200,000+ | 33% | Extensive (Gerber, BOM, WiFi-Mesh, Raspberry Pi integration) | Custom Manufacturer |

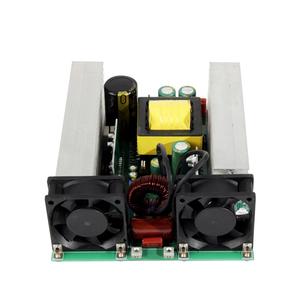

| Shenzhen Wenzhan Electronic Technology Co., Ltd. | SMT Assembly Lines, Conveyors, Loaders, Production Machinery | 97% | ≤2h | US $560,000+ | <15% | Equipment-focused | N/A |

| Shenzhen Xuyuxin Technology Co., Ltd. | PCBA, One-Stop OEM Services | 100% | ≤1h | Not specified | - | Basic to mid-level customization | N/A |

Performance Analysis

Toptek Pcb Co., Limited and Shenzhen Xuyuxin Technology stand out with perfect on-time delivery records and sub-1-hour response times, indicating strong customer service orientation. King Field Electronic demonstrates deeper customization capacity, supporting advanced features like Wi-Fi mesh integration and reverse engineering, backed by significant annual online revenue (US $200,000+). Shenzhen Wenzhan distinguishes itself as an equipment provider rather than a contract assembler, offering full SMT production lines—a critical resource for buyers establishing internal manufacturing. Reorder rates vary widely, suggesting divergent post-sale satisfaction levels; suppliers with higher repeat business (e.g., Toptek at 66%) may offer superior long-term reliability.

FAQs

How to verify PCB SMT assembly supplier reliability?

Assess on-time delivery history, response speed, and technical capability tags such as impedance control or lead-free finishing. Request process flow documentation including stencil printing, reflow profiles, and inspection protocols. Validate component sourcing practices and confirm use of AOI/X-ray for defect detection.

What is the typical lead time for SMT assembly orders?

Prototype batches (1–100 pcs) typically take 5–8 days. Medium-volume orders (1,000–10,000 pcs) require 10–15 days, while large-scale production may extend to 18–25 days depending on complexity and component availability.

Do suppliers support low MOQs and prototyping?

Yes, most suppliers listed accept MOQs as low as 1 piece, making them suitable for R&D and pilot testing. Unit pricing decreases significantly at volumes above 500 pieces, with some suppliers offering tiered pricing down to $0.10 per unit.

Can suppliers handle component procurement?

Many offer full turnkey services, managing BOM fulfillment, alternative part selection, and counterfeit component mitigation. Suppliers like King Field explicitly list component sourcing as a core competency, reducing buyer overhead in supply chain coordination.

What file formats are required for SMT processing?

Standard requirements include Gerber files (RS-274X), NC drill files, bill of materials (BOM), and centroid data for pick-and-place machines. Some suppliers accept 3D STEP models or Eagle/KiCad project files for design verification.