Perforating Machine For Paper Sheets Wholesaler

About perforating machine for paper sheets wholesaler

Where to Find Perforating Machine for Paper Sheets Wholesalers?

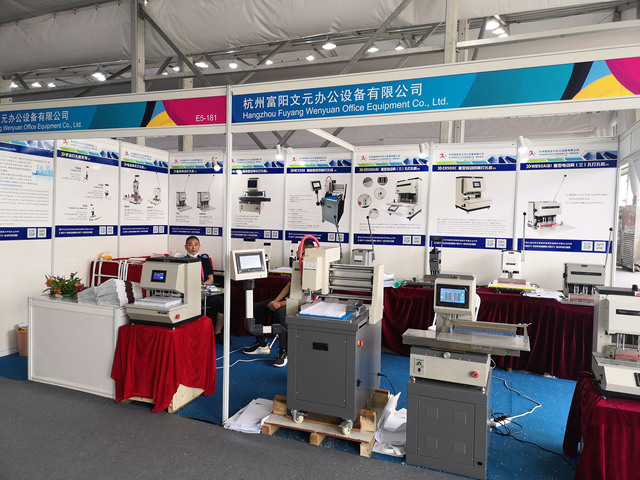

China remains the dominant hub for perforating machine manufacturing, with key supplier clusters concentrated in Zhejiang and Henan provinces. Hangzhou in Zhejiang hosts a high concentration of precision paper processing equipment manufacturers, leveraging advanced CNC machining and electronics integration capabilities. Zhengzhou, the industrial center of Henan, serves as a logistics and production nexus for mid-to-heavy-duty paper machinery, offering streamlined access to rail and freight networks for bulk export.

These regional ecosystems support vertically integrated production—from sheet metal fabrication to control system assembly—enabling suppliers to maintain tight tolerances and rapid turnaround. Buyers benefit from localized supply chains that reduce component lead times by 20–30% compared to offshore alternatives. The average standard order lead time ranges from 15 to 30 days, with economies of scale allowing competitive pricing across manual, semi-automatic, and fully automated models. Suppliers in these regions commonly serve global markets, including North America, Europe, and Southeast Asia, with compliance-focused engineering practices.

How to Choose Perforating Machine for Paper Sheets Wholesalers?

Selecting reliable suppliers requires structured evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

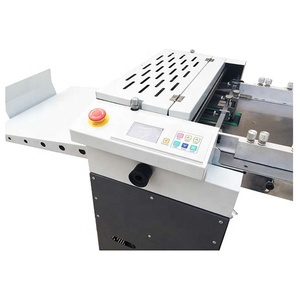

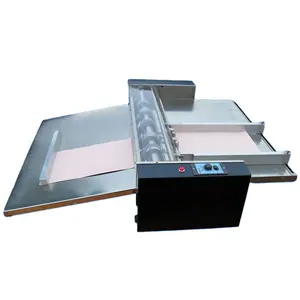

Assess machine specifications against intended use cases: manual desktop units (e.g., A3/A4) suit low-volume offices, while digital or roll-fed automatic systems are designed for industrial throughput. Confirm compatibility with material thickness (typically 80–400gsm), creasing width (up to 520mm), and customization options such as multi-layer cutting, numbering, or slitting integration. For automated models, verify motor power, feeding mechanism type (digital/servo-driven), and programmable logic controller (PLC) interfaces.

Production and Quality Assurance Standards

Prioritize suppliers demonstrating consistent quality control through documented processes. While formal ISO 9001 certification is not universally listed, performance indicators such as on-time delivery rates exceeding 97% and response times under 3 hours correlate with operational discipline. Evaluate customization capacity—key parameters include blade configuration, logo imprinting, packaging design, and voltage compatibility (110V/220V).

Transaction and Sourcing Safeguards

Use secure payment mechanisms such as escrow services to mitigate risk during initial procurement. Analyze reorder rates as a proxy for customer satisfaction; suppliers with rates above 35% indicate stronger reliability and post-sale support. Request product videos or facility walkthroughs to validate claims about automation level and build quality. Pre-shipment inspection (PSI) protocols should be available upon request, particularly for orders exceeding $5,000.

What Are the Best Perforating Machine for Paper Sheets Wholesalers?

| Company Name | Location | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Product Range | Price Range (USD) | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Zhengzhou Zomagtc Co., Ltd. | Henan, CN | $1.3M+ | 100% | ≤2h | 43% | 5 | $2,500–$55,429 | Yes |

| Zhengzhou Allraise Company Ltd. | Henan, CN | $590K+ | 100% | ≤2h | 35% | 4 | $400–$3,350 | Yes |

| Hangzhou Gino Tech Co., Ltd. | Zhejiang, CN | $610K+ | 97% | ≤3h | <15% | 5 | $135–$1,360 | Yes |

| Hangzhou Caide Office Equipment Co.,ltd | Zhejiang, CN | $370K+ | 98% | ≤3h | <15% | 5 | $120–$2,800 | Yes |

| Suzhou Ruicai Electron Co., Ltd. | Jiangsu, CN | $180K+ | 96% | ≤10h | <15% | 5 | $60–$5,080 | Limited |

Performance Analysis

Zhengzhou-based suppliers demonstrate superior fulfillment reliability with 100% on-time delivery and high reorder rates, suggesting robust production planning and customer service. Zomagtc leads in revenue volume and offers the widest price spectrum, including heavy-duty roll-to-sheet systems priced over $50,000, indicating capability for large-scale industrial contracts. Allraise presents a cost-effective alternative for mid-range automated solutions with strong transactional performance.

Zhejiang-based suppliers like Gino Tech and Caide focus on entry-level to mid-tier desktop and electric models, offering competitive pricing and extensive customization but lower reorder rates, which may reflect higher buyer acquisition costs or variability in after-sales support. Suzhou Ruicai provides the lowest-cost manual units, suitable for small businesses or prototyping, though slower response times suggest limited staffing for international inquiries.

For high-volume procurement, prioritize suppliers with verified customization workflows, sub-3-hour response times, and minimum reorder rates above 30%. For niche applications requiring multi-function integration (e.g., creasing, numbering, laminating), confirm technical feasibility through sample testing and engineering consultation prior to full-scale ordering.

FAQs

How to verify perforating machine supplier reliability?

Cross-check delivery performance data with third-party transaction records where available. Request reference customers or case studies for machines in your target application range. Validate customization capabilities through prototype samples and assess build quality via video inspection of core components such as rollers, blades, and drive systems.

What is the typical MOQ and lead time?

Most suppliers list a minimum order quantity of 1 unit/set, facilitating pilot purchases. Standard lead times range from 15 to 25 days for ready-to-ship models. Custom configurations may extend production timelines by 10–15 days depending on complexity.

Can suppliers accommodate OEM/ODM requests?

Yes, multiple suppliers explicitly offer OEM services including custom branding, color schemes, packaging labels, and interface graphics. Technical modifications such as blade layout, folding width, or voltage adjustment are commonly supported upon request.

Do perforating machines comply with international safety standards?

While specific CE or RoHS certifications are not detailed in listings, many suppliers design equipment for export markets with insulated electrical systems, emergency stop functions, and protective guards. Buyers should explicitly request compliance documentation before finalizing orders for regulated regions.

What are the shipping and logistics options?

Suppliers typically offer FOB terms with consolidation options via air or sea freight. For heavy machinery (e.g., roll-to-sheet systems), sea shipment is recommended to manage transport costs. Confirm packaging methods (wooden crate vs. carton) and insurance coverage to protect against transit damage.