Perforating Machine Distributor

About perforating machine distributor

Where to Find Perforating Machine Distributors?

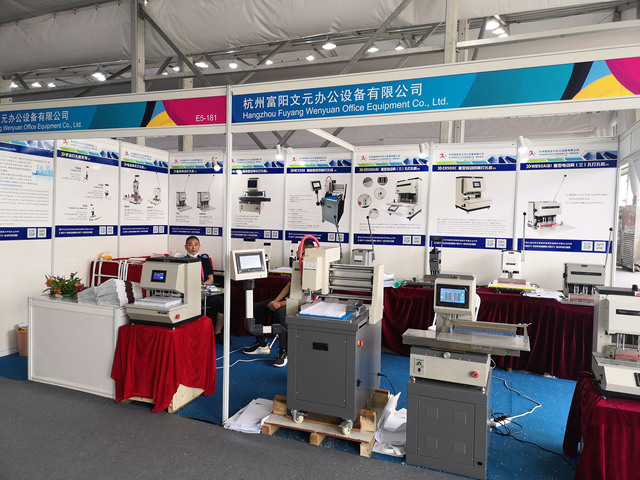

China remains the global epicenter for perforating machine manufacturing, with key supplier clusters concentrated in Henan and Zhejiang provinces. Zhengzhou, Henan's capital, hosts a dense network of industrial machinery producers specializing in paper and metal processing equipment, leveraging regional logistics advantages and vertically integrated supply chains. Hangzhou in Zhejiang province has emerged as a hub for compact, precision-engineered desktop models targeting small-to-medium enterprises and print finishing operations.

These regional ecosystems enable cost efficiencies through localized component sourcing—steel, motors, cutting dies—and streamlined assembly processes. Suppliers in these zones typically operate under consolidated production frameworks, allowing rapid prototyping and scalable output. Buyers benefit from lead times averaging 20–35 days for standard units, with cost savings of 25–40% compared to equivalent Western-made machines. The proximity of material suppliers, R&D centers, and export terminals within 50 km supports agile fulfillment for both bulk orders and customized configurations.

How to Choose Perforating Machine Distributors?

Effective supplier selection requires structured evaluation across technical, operational, and transactional dimensions:

Technical Specifications & Compliance

Verify machine compatibility with intended materials (paper, cardboard, plastic film, or metal sheets) and required output precision. For international buyers, ensure CE marking or equivalent safety certification is provided. Request documentation on motor power, stroke rate, die-cutting accuracy, and maximum sheet size to validate performance claims.

Production and Customization Capacity

Assess supplier capabilities based on the following indicators:

- Minimum factory area exceeding 1,000m² for reliable volume production

- In-house design and tooling teams capable of modifying blade configurations, feed mechanisms, or control systems

- Proven experience with OEM/ODM services, including branding, packaging, and voltage adjustments

Cross-reference customization claims with product listings showing variable parameters such as creasing width, roll-to-roll integration, or multi-die setups.

Transaction Reliability Metrics

Prioritize partners demonstrating consistent delivery performance (target ≥95%) and sub-4-hour response times. Analyze reorder rates as proxies for customer satisfaction—suppliers with reorder rates above 30% often provide superior after-sales support and machine durability. Confirm use of secure payment escrow systems and pre-shipment inspection protocols to mitigate procurement risk.

What Are the Leading Perforating Machine Distributors?

| Company Name | Location | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Product Range | Min. Order | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Zhengzhou Zomagtc Co., Ltd. | Henan, CN | US $1.3M+ | 100% | ≤2h | 36% | Digital creasing, roll-to-roll, notebook forming | 1 set | Color, size, thickness, logo, packaging |

| Zhengzhou Miles Tech Company Ltd. | Henan, CN | US $980K+ | 92% | ≤3h | 15% | Paper creasing, invoice perforators, industrial A2/A3 | 1 set | Material, folding length, die pattern, packaging |

| Hangzhou Gino Tech Co., Ltd. | Zhejiang, CN | US $610K+ | 98% | ≤2h | <15% | Desktop electric, multifunctional BOPP film | 1 piece | Blade type, LCD controls, plug, paper roller |

| Shandong Soar Machinery Co., Ltd. | Shandong, CN | US $390K+ | 85% | ≤4h | 15% | Pipe perforating, metal mesh making | 1 piece/set | Pipe diameter, material thickness, logo |

| Guangzhou Kingreal Machinery Co., Ltd. | Guangdong, CN | US $240K+ | 100% | ≤2h | <15% | Metal sheet micro-perforation, ceiling tile lines | 1 set | Size, material, panel design, packaging |

Performance Analysis

Zhengzhou Zomagtc stands out with the highest reorder rate (36%) and perfect on-time delivery, indicating strong post-purchase reliability and customer retention. Its focus on high-speed digital and automated systems positions it as a preferred partner for mid-volume printing and packaging operations. Hangzhou Gino Tech offers entry-level desktop models starting below $150 per unit, catering to niche markets requiring low MOQs and compact footprints. Shandong Soar and Guangzhou Kingreal specialize in heavy-duty industrial applications, with metal perforation systems priced between $27,500 and $45,000—suitable for construction and automotive sectors. While their reorder rates are lower, their 100% on-time delivery records suggest disciplined production planning.

FAQs

What is the typical minimum order quantity for perforating machines?

Most suppliers list a minimum order of 1 set or piece, particularly for standalone units. Bulk pricing becomes available at 5+ units for smaller models, while large industrial systems are typically quoted individually due to customization requirements.

How long does production and shipping take?

Standard machine production takes 20–30 days. Add 15–25 days for air or sea freight depending on destination. Complex customizations may extend lead times by an additional 10–15 days.

Do suppliers offer customization options?

Yes, all listed suppliers provide customization across parameters such as material thickness, blade configuration, voltage, control interface, and branding. High-end models support full OEM packaging and tailored mechanical specifications like rewinding width or slitting capacity.

Can I request a sample before placing a full order?

While full-machine samples are rare due to size and cost, suppliers often allow test runs with video verification or provide partial component samples (e.g., perforated strips). Some waive sampling fees upon confirmation of future volume orders.

What quality assurance measures should I verify?

Request evidence of ISO 9001 compliance, CE certification, and internal QC procedures. Ask for machine test reports, component sourcing details, and access to factory audit videos. Third-party inspection services can be arranged prior to shipment for high-value purchases.