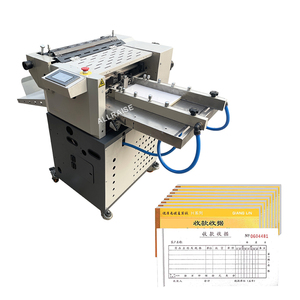

Creasing And Perforating Machine Distributor

1/19

1/19

1/17

1/17

1/10

1/10

1/19

1/19

1/13

1/13

1/12

1/12

1/3

1/3

1/3

1/3

1/3

1/3

1/2

1/2

0

0

1/3

1/3

1/3

1/3

1/3

1/3

1/15

1/15

1/16

1/16

1/3

1/3

1/3

1/3

About creasing and perforating machine distributor

Where to Find Creasing and Perforating Machine Suppliers?

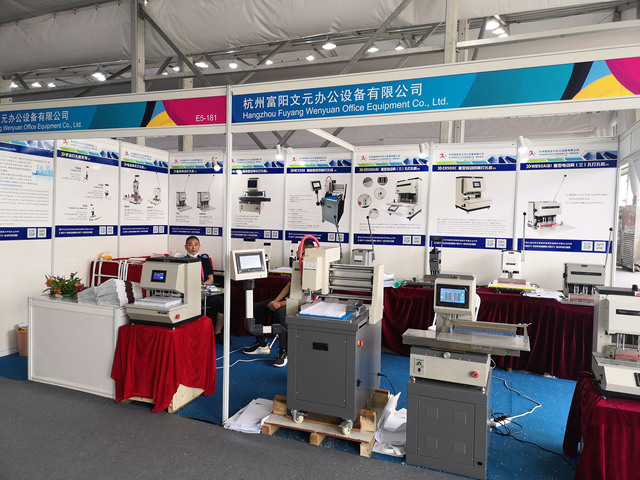

China remains the central hub for creasing and perforating machine manufacturing, with a concentrated supplier base in Hangzhou, Zhejiang Province. This region hosts multiple specialized industrial clusters focused on precision paper processing equipment, leveraging mature supply chains for motors, blades, control systems, and structural components. The proximity of component suppliers and assembly facilities enables streamlined production cycles and rapid prototyping capabilities.

These ecosystems support both high-volume OEM output and low-volume customized builds, with integrated logistics networks facilitating efficient export operations. Buyers benefit from localized expertise in digital control integration, pneumatic feeding systems, and multi-functional design engineering. Typical advantages include reduced material procurement lead times (often under 7 days), access to modular machine architectures, and cost efficiencies derived from economies of scale—production costs averaging 20–35% below those of European or North American manufacturers.

How to Choose Creasing and Perforating Machine Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

Confirm that suppliers offer machines compliant with international safety standards such as CE, particularly for electric drive systems and operator protection mechanisms. Evaluate product specifications for key performance indicators: maximum sheet size (e.g., A3 to 480mm+), creasing accuracy (±0.1mm tolerance), and programmable memory functions. For automated models, verify inclusion of infrared sensors, servo-driven feeding, and CCD camera alignment where applicable.

Production Infrastructure Assessment

Prioritize suppliers demonstrating verifiable manufacturing capacity through:

- In-house R&D teams capable of customizing blade spacing, motor power, and control interfaces

- Facility-scale operations supported by CNC machining and welding infrastructure

- Demonstrated customization options including color, material finish, logo imprinting, and packaging configuration

Cross-reference online revenue data and on-time delivery rates (target ≥98%) as proxies for operational stability and order fulfillment reliability.

Procurement Risk Mitigation

Utilize secure payment frameworks such as escrow services to align payment release with shipment and inspection milestones. Analyze reorder rates—those below 15% may indicate limited customer retention despite strong initial service metrics. Request physical or digital samples to assess build quality, noise levels, and functional precision prior to bulk ordering. Lead times typically range from 15–30 days depending on customization scope and order volume.

What Are the Best Creasing and Perforating Machine Suppliers?

| Company Name | Location | Online Revenue | On-Time Delivery | Response Time | Reorder Rate | Customization Options | Min. Order Quantity | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Zhejiang Daxiang Office Equipment Co., Ltd. | Zhejiang, CN | US $1,500,000+ | 100.0% | ≤2h | <15% | Yes | 1 set/piece | $120–650 |

| Hangzhou Gino Tech Co., Ltd. | Zhejiang, CN | US $650,000+ | 99.0% | ≤2h | <15% | Yes | 1 set/piece | $334–2,800 |

| Hangzhou Caide Office Equipment Co.,ltd | Zhejiang, CN | US $330,000+ | 98.0% | ≤3h | <15% | Yes | 1–2 pieces | $25–1,600 |

| Hangzhou Befitter Machinery & Electronic Co., Ltd. | Zhejiang, CN | US $270,000+ | 93.0% | ≤5h | 24% | Yes | 1–5 pieces | $108–1,360 |

| HangZhou Fuyang Huibao Hansway Trading Co.Ltd | Zhejiang, CN | US $150,000+ | 92.0% | ≤4h | <15% | Yes | 1–5 units | $1,560–10,999 |

Performance Analysis

Zhejiang Daxiang leads in delivery consistency and response speed, achieving a perfect 100% on-time rate with sub-2-hour communication latency—ideal for time-sensitive procurement. Hangzhou Gino Tech demonstrates robust scalability, backed by the second-highest revenue and advanced features like LCD controls and slitting blade integration. While most suppliers maintain low reorder rates (<15%), Hangzhou Befitter stands out with a 24% repeat order rate, suggesting stronger post-sale satisfaction despite slightly longer response windows. High-end offerings, such as Boway’s $10,999 precision die-cutting model, cater to industrial-grade applications requiring tight tolerances and servo motor control.

FAQs

How to verify creasing and perforating machine supplier reliability?

Validate compliance with CE or equivalent safety certifications. Review supplier tags for evidence of customization capability, responsive communication, and consistent delivery performance. Examine product listings for technical detail depth—comprehensive specifications suggest higher engineering maturity.

What is the typical minimum order quantity (MOQ)?

MOQs vary from 1 piece/set for standard models to 5 units for discounted configurations. Some manual or desktop variants allow mixed-carton orders at lower volumes. Customized units typically require MOQs of 1–5 sets depending on modification complexity.

Can suppliers provide machine customization?

Yes, all listed suppliers offer customization options ranging from logo printing and color selection to blade configuration, material thickness adjustment, and control panel language settings. Advanced modifications—including UV sensing, hand protection systems, and servo-driven feeding—require direct consultation and technical documentation submission.

What are common lead times for delivery?

Standard orders are typically fulfilled within 15–25 days after confirmation. Customized machines may require 30–45 days depending on design changes and component availability. Air freight shipping adds 7–10 days internationally; sea freight ranges from 25–40 days based on destination port.

Do suppliers support global shipping?

Yes, all listed companies have established export channels. Confirm Incoterms (FOB, CIF) during negotiation and ensure compliance with local electrical and machinery import regulations. Most suppliers partner with international carriers and can provide freight quotations upon request.