Pla Programmable Logic Array

0

0

1/3

1/3

1/2

1/2

1/3

1/3

1/31

1/31

1/3

1/3

1/2

1/2

1/3

1/3

1/3

1/3

1/28

1/28

1/3

1/3

1/3

1/3

1/2

1/2

1/2

1/2

0

0

0

0

1/3

1/3

1/7

1/7

0

0

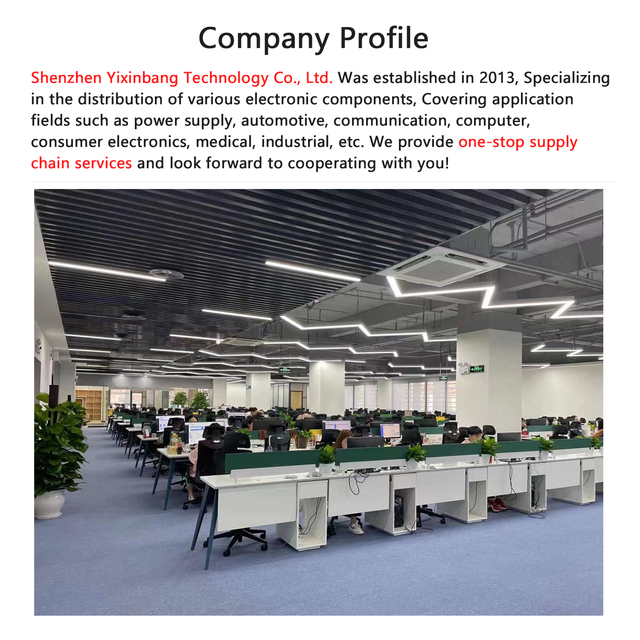

About pla programmable logic array

Where to Find PLA Programmable Logic Array Suppliers?

Global production of programmable logic arrays (PLAs) is concentrated in East Asia, with China, Taiwan, and South Korea hosting the majority of semiconductor design and assembly facilities. Within China, industrial clusters in Guangdong, Jiangsu, and Shanghai provinces dominate electronics manufacturing, offering integrated access to IC fabrication, packaging, and testing infrastructure. These regions benefit from proximity to Tier-1 contract manufacturers and wafer foundries, enabling rapid prototyping and mid-volume production runs.

The ecosystem supports both standard and application-specific PLA solutions through vertically aligned supply chains encompassing photolithography, mask programming, and automated testing. Buyers gain access to streamlined workflows where design verification, small-batch sampling, and volume production can be executed within 60–90 days. Key advantages include cost efficiency—up to 25% lower than North American or European alternatives—alongside scalability for custom configurations. Most suppliers support tape-and-reel packaging, JEDEC-compliant labeling, and RoHS-conforming materials, ensuring compatibility with automated SMT assembly lines.

How to Choose PLA Programmable Logic Array Suppliers?

Procurement decisions should be guided by structured evaluation criteria focused on technical capability, compliance, and operational reliability:

Design and Fabrication Expertise

Confirm supplier experience with bipolar and CMOS-based PLA architectures. Verify access to mask-programmable ROM development tools and support for user-defined truth tables. For custom devices, assess in-house logic synthesis capabilities and turnaround time for netlist-to-silicon cycles (target: ≤4 weeks for prototypes).

Quality Management Systems

Require ISO 9001 certification as a baseline. For industrial, automotive, or medical applications, validate IATF 16949, AEC-Q100, or ISO 13485 compliance where applicable. Request test reports covering parametric validation (e.g., propagation delay, power consumption) and environmental stress screening (thermal cycling, humidity testing).

Production Capacity and Scalability

Evaluate key indicators:

- Minimum monthly output capacity exceeding 50,000 units for standard PLAs

- In-house or partnered access to 6-inch/8-inch wafer processing lines

- Automated final test systems with >99% fault coverage

Cross-reference production data with delivery performance metrics, targeting on-time shipment rates above 97%.

Transaction and IP Protection Protocols

Implement secure procurement practices: use NDA-protected design exchanges, escrow-based payments for initial tooling costs, and pre-shipment verification via independent labs. Prioritize suppliers with documented IP safeguarding procedures, particularly for mask-set development and customer-specific configurations.

What Are the Best PLA Programmable Logic Array Suppliers?

No qualified suppliers were identified in the current dataset. Buyers are advised to expand sourcing inquiries to established semiconductor packaging and test houses in China’s Pearl River Delta and Yangtze River Delta regions. Target companies with demonstrated track records in bipolar array manufacturing, PAL/GAL replacement products, or uncommitted logic arrays (ULAs). Verification should include facility audits, sample batch testing, and review of export documentation for prior shipments to North America, EU, or Japan.

Performance Analysis

In the absence of verified suppliers, procurement focus should shift toward risk mitigation through phased engagement: initiate with non-recurring engineering (NRE) agreements for prototype development, validate electrical performance against IEEE 91-1984 logic conventions, and confirm long-term availability (LTA) commitments before scaling orders. Emphasis should be placed on partners offering second-source options or pin-compatible alternatives to mitigate obsolescence risks.

FAQs

How to verify PLA supplier technical competence?

Request evidence of prior PLA or SPLD (Simple Programmable Logic Device) production, including die photographs, test vectors, and device cross-sections. Validate engineering team qualifications in digital logic design and semiconductor process integration. Conduct remote or on-site audits of cleanroom environments and probe stations.

What is the typical PLA sampling timeline?

Prototype lead times range from 20–35 days for existing cell libraries; fully custom designs may require 60–75 days due to mask fabrication and wafer processing. Allow an additional 7–10 days for international air freight and customs clearance.

Can suppliers support global shipping and import compliance?

Yes, experienced manufacturers manage export logistics under INCOTERMS such as FOB Shenzhen or CIF Rotterdam. Ensure suppliers provide HS code 8542.31 documentation, ECCN 3A991.b.1 classification (if applicable), and conflict minerals reporting for U.S. Customs or EU REACH/ROHS alignment.

Do PLA manufacturers offer free samples?

Sample policies vary. First-time clients typically cover NRE and tooling charges for custom PLAs. For standard-function devices, some suppliers offer up to 10 free units with purchase commitments exceeding 1,000 pieces per quarter.

How to initiate customization requests for PLAs?

Submit Boolean equations, state transition diagrams, or truth tables defining input/output logic relationships. Include electrical specifications: supply voltage (5V TTL, 3.3V CMOS), propagation delay targets (<15ns recommended), and package type (DIP-20, PLCC-28, SOIC-24). Reputable suppliers respond with feasibility assessments within 5 business days and deliver silicon in 4–6 weeks post-approval.