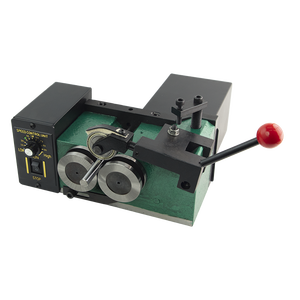

Precision Machine Tool

About precision machine tool

Where to Find Precision Machine Tool Suppliers?

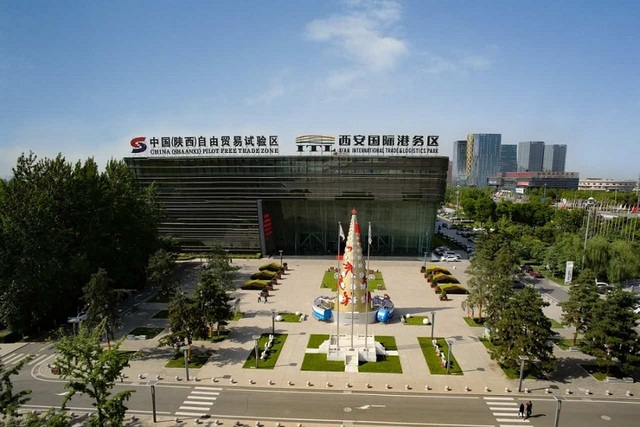

China remains the global epicenter for precision machine tool manufacturing, with key industrial hubs in Guangdong, Shandong, and Shaanxi provinces driving innovation and scale. Dongguan and Shenzhen in Guangdong province host advanced CNC component clusters, leveraging proximity to electronics and automotive supply chains to optimize just-in-time delivery. Shandong’s Jinan and Tengzhou regions specialize in high-precision accessories and modular tooling systems, supported by mature metallurgical infrastructure that ensures consistent material quality. Xi’an in Shaanxi province serves as a center for heavy-duty manual and CNC lathes, benefiting from decades of state-backed industrial engineering expertise.

These regional ecosystems enable vertically integrated production—from raw material processing to final assembly—reducing lead times and logistics overhead. Suppliers within these zones typically operate within tightly networked supply chains, where spindle manufacturers, casting foundries, and control system integrators are located within 50–100km. This integration supports rapid prototyping, batch customization, and scalable output, with standard order fulfillment averaging 30–45 days. Buyers benefit from 15–25% cost advantages over Western or Southeast Asian alternatives, particularly for complex machining centers and specialty tooling.

How to Choose Precision Machine Tool Suppliers?

Effective supplier selection requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Quality Assurance

Confirm adherence to international standards such as ISO 9001 for quality management and CE marking for electrical and mechanical safety compliance. For high-precision applications, verify documented testing procedures for critical parameters including runout accuracy (<0.005mm), spindle concentricity, and thermal stability under continuous load. Suppliers should provide calibration certificates and dimensional inspection reports upon request.

Production Capability Assessment

Evaluate core manufacturing competencies through the following indicators:

- Minimum facility size of 2,000m² for dedicated CNC machining and assembly lines

- In-house R&D capacity focused on tool path optimization, vibration damping, and positioning accuracy

- Integration of precision grinding, hardening, and surface finishing processes

Cross-reference online revenue data and reorder rates (e.g., >30% indicates strong customer retention) with on-time delivery performance (target ≥95%) to assess operational reliability.

Customization & Support Infrastructure

Prioritize suppliers offering configurable options for control systems (Fanuc, Siemens, Mach3), spindle speeds, tool interfaces (BT, HSK, ER), and language localization. Verify availability of digital support assets such as 3D models, operation manuals, and maintenance guides. Response time ≤3 hours and multilingual technical support enhance post-purchase serviceability.

Transaction Security & Sampling Protocols

Utilize secure payment mechanisms with milestone-based disbursement tied to production verification. Request physical or digital samples to validate build quality, surface finish, and functional performance. Benchmark cutting tools against ISO 5272 (collets), DIN 69871 (tool holders), or ASME B5.50 (spindle interfaces) where applicable.

What Are the Best Precision Machine Tool Suppliers?

| Company Name | Location | Main Products | On-Time Delivery | Reorder Rate | Avg. Response | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|---|

| Dongguan Lize Precision Mold Co., Ltd. | Guangdong, CN | Punch grinders, precision adjustment tools, industrial punches | 86% | 20% | ≤3h | US $50,000+ | Not specified |

| Shandong Weier Cnc Machine Tool Accessories Co., Ltd. | Shandong, CN | Hydraulic vises, collets, ER tooling, HSK side lock adapters | 91% | <15% | ≤4h | US $110,000+ | Limited |

| Xi'an Premier Machine Tools Co., Ltd. | Shaanxi, CN | Manual lathes, boring machines, drilling machines | 100% | <15% | ≤3h | US $20,000+ | Not specified |

| Tengzhou Borui CNC Machine Tool Co., Ltd. | Shandong, CN | CNC milling machines, vertical machining centers, 5-axis CNC systems | 100% | 39% | ≤2h | US $780,000+ | Extensive (spindle, control system, size, logo, packaging) |

| Dongguan Jinsheng CNC Tool Co., Ltd. | Guangdong, CN | CNC engraving tools, chamfering cutters, BT30 tool holders | 100% | 33% | ≤1h | US $10,000+ | Not specified |

Performance Analysis

Tengzhou Borui CNC Machine Tool Co., Ltd. stands out with the highest online revenue (US $780,000+), perfect on-time delivery (100%), and an extensive customization framework covering control systems, materials, and branding—making it ideal for buyers requiring tailored CNC machining centers. Its 39% reorder rate reflects strong product satisfaction. Dongguan Jinsheng CNC Tool Co., Ltd. excels in responsiveness (≤1h) and customer retention (33% reorder rate), suitable for fast-turnaround tooling needs. Xi’an Premier and Shandong Weier focus on foundational machine components and manual equipment, offering value-driven solutions for budget-conscious procurement. Dongguan Lize provides mid-tier industrial punches and grinders with moderate delivery performance (86%).

FAQs

How to verify precision machine tool supplier reliability?

Validate certifications (ISO, CE) through issuing body databases. Request factory audit reports or video tours confirming CNC machining centers, quality inspection stations, and inventory management systems. Analyze transaction metrics such as on-time delivery rate (>95% recommended) and reorder frequency to gauge dependability.

What is the typical MOQ and pricing range?

MOQs vary by product type: single units for complete machines (e.g., lathes, milling systems) and 10+ pieces for cutting tools and accessories. Prices range from $0.85 for ER collets to $28,500 for high-end 5-axis CNC machining centers. Bulk discounts are commonly available for orders exceeding 5 sets.

Do suppliers offer customization for CNC machine tools?

Yes, leading suppliers like Tengzhou Borui support full customization including control software (Fanuc, Siemens, Syil), spindle configurations, worktable dimensions, and OEM labeling. Technical specifications must include required accuracy (e.g., ±0.005mm), RPM range, tool magazine capacity, and interface standards.

What are standard lead times for precision machine tools?

Standard orders typically ship within 30–45 days after deposit confirmation. Customized CNC systems may require 60–75 days for design validation, component sourcing, and final assembly. Express production (20–25 days) is sometimes available at a premium.

Can precision machine tools be shipped internationally?

Yes, most suppliers export globally via sea freight (FCL/LCL) or air cargo for urgent components. Ensure compliance with destination regulations regarding voltage (220V/380V), CE marking, and machinery safety directives. Suppliers should provide packing lists, commercial invoices, and bill of lading documentation.