Toolco Precision Machine

CN

CN

CN

CN

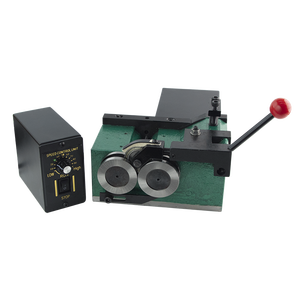

About toolco precision machine

Where to Find Toolco Precision Machine Suppliers?

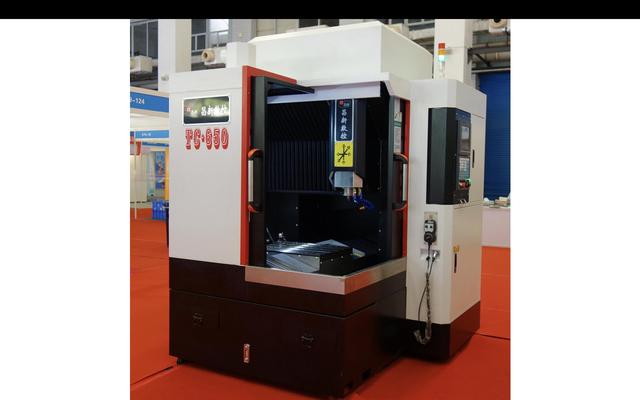

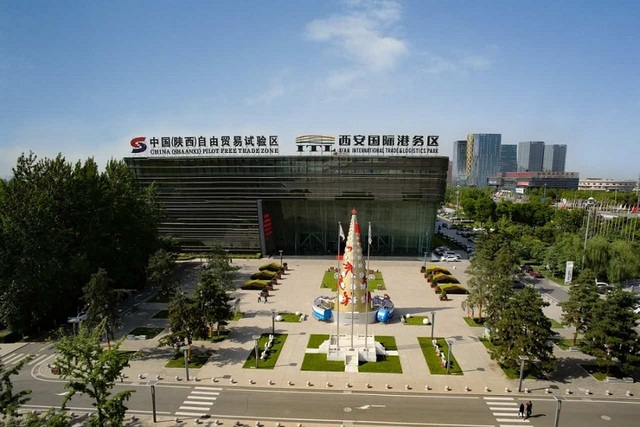

China remains the central hub for precision machine manufacturing, with key supplier clusters located in Jiangxi, Guangdong, Zhejiang, and Jiangsu provinces. These regions host vertically integrated industrial ecosystems specializing in CNC machining centers, lathes, milling machines, and tooling systems. Jiangxi and Jiangsu are particularly known for their focus on high-precision metal-cutting equipment, supported by mature supply chains for cast iron components, servo motors, and linear guides. Proximity to Shanghai and Ningbo ports enables efficient export logistics, reducing outbound shipping lead times by 7–10 days compared to inland competitors.

The concentration of engineering talent and component suppliers within 50km radii allows for rapid prototyping and assembly. This infrastructure supports competitive production cycles, with standard machine delivery typically achievable within 30–45 days. Buyers benefit from localized sourcing of critical subsystems—such as ball screws and spindle units—reducing overall costs by 20–25% versus equivalent Western-manufactured machinery. The region’s specialization also facilitates customization, including voltage adjustments (380V/50Hz to 220V/60Hz), control system integration (Fanuc, Siemens, or Syntec), and structural modifications for specialized workpiece dimensions.

How to Choose Toolco Precision Machine Suppliers?

Selecting reliable partners requires a structured evaluation across technical, operational, and transactional criteria:

Technical & Quality Compliance

Confirm adherence to international quality standards such as ISO 9001. For markets in Europe and North America, CE marking is essential for regulatory compliance and customs clearance. Request documentation on material certifications (e.g., GGG40 for cast bases) and geometric accuracy testing (e.g., laser interferometer reports for positioning repeatability). Verify spindle runout tolerance (typically ≤0.005mm) and surface finish capability (Ra ≤1.6μm) through sample machining records.

Production Capacity Assessment

Evaluate supplier infrastructure based on the following benchmarks:

- Minimum factory area of 3,000m² for dedicated CNC assembly lines

- In-house machining capabilities including milling, turning, and grinding for critical subcomponents

- Integration of digital design tools (SolidWorks, AutoCAD) and electrical control programming (PLC/HMI)

- On-time delivery performance exceeding 95%, indicating stable production planning

Cross-reference self-reported capabilities with verifiable metrics such as online revenue indicators and order fulfillment history where available.

Procurement Risk Mitigation

Utilize secure payment mechanisms such as third-party escrow services to align payment milestones with delivery and inspection phases. Prioritize suppliers offering pre-shipment inspection (PSI) options, either through independent agencies or client-appointed representatives. Conduct virtual audits via live video tours to validate workshop conditions, inventory levels, and quality control stations before placing bulk orders.

What Are the Best Toolco Precision Machine Suppliers?

| Company Name | Location | Main Products | Price Range (USD) | MOQ | On-Time Delivery | Avg. Response | Customization | Online Revenue |

|---|---|---|---|---|---|---|---|---|

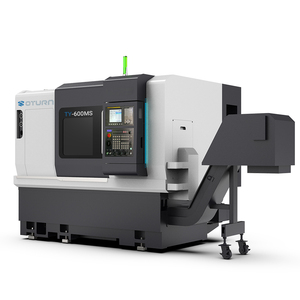

| Jiangxi Yinko Precision Machinery Co., Ltd. | Jiangxi, CN | CNC Lathes, Manual Mills, Machining Centres | $2,000–$9,600 | 1 set | 100% | ≤4h | Not specified | Not disclosed |

| EMCO ENGINEERING PRIVATE LIMITED | Tamil Nadu, IN | Grinding Equipment, Vertical/Horizontal Mills | $1,450–$5,500 | 1 set | Not disclosed | ≤24h | Not specified | Not disclosed |

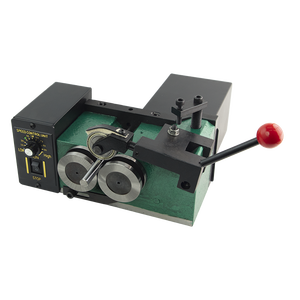

| Guangzhou Jeefoo Tool Co., Ltd. | Guangdong, CN | Milling Cutters, Drill Bits, Machine Tool Accessories | $3.85/unit | 30 pieces | 76% | ≤2h | Not specified | US $10,000+ |

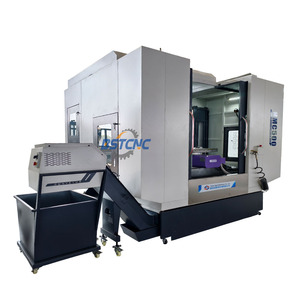

| Ningbo Kula Precision Machinery Co., Ltd. | Zhejiang, CN | 5-Axis CNC, Turning Centers, High-Efficiency Lathes | $52,600–$250,800 | 1 set | 100% | ≤2h | Color, Material, Size, Logo, Packaging | Not disclosed |

| Nanjing Longbo Machine Tool Co., Ltd. | Jiangsu, CN | Pipe Bending Machines, CNC Grooving Systems | $1,480–$12,800 | 1 set/piece | 100% | ≤2h | Not specified | US $2,000+ |

Performance Analysis

Jiangxi Yinko and Ningbo Kula demonstrate strong reliability with 100% on-time delivery and responsive communication (≤4h response). Ningbo Kula stands out for high-end offerings, including 5-axis CNC systems priced above $250,000, indicating advanced engineering and build capacity. Nanjing Longbo offers cost-effective entry-level automation with small-tonnage CNC benders starting at $1,480, suitable for niche fabrication applications. Guangzhou Jeefoo focuses on consumable tooling rather than full machine systems, serving as a complementary supplier for cutting accessories. EMCO Engineering provides competitively priced grinding and milling solutions but lacks verified delivery performance data, suggesting potential risk in fulfillment consistency.

FAQs

How to verify precision machine supplier credibility?

Request copies of ISO 9001 or CE certificates and validate them through issuing bodies. Ask for machine test videos, dimensional inspection reports, and customer references in your target market. Review transaction histories on business platforms for dispute resolution patterns and after-sales service responsiveness.

What is the typical lead time for precision machines?

Standard models generally require 30–45 days for production and preparation. Custom-configured machines, especially multi-axis CNC systems, may take 60–90 days depending on complexity. Shipping via sea freight adds 20–35 days for trans-Pacific or trans-Europe routes.

Do suppliers support OEM/ODM services?

Yes, select manufacturers like Ningbo Kula offer comprehensive customization, including brand labeling, color schemes, control panel layouts, and packaging design. Minimum requirements vary; some accept branding on single-unit orders, while others require minimum batches of 5–10 units.

Are samples available for precision machinery?

Full-machine sampling is uncommon due to size and cost but can be arranged under consignment or rental terms. Alternatively, suppliers may provide machining samples using client-specified materials and tolerances. Expect sample fees ranging from 30% to 100% of unit price, often creditable toward future orders.

What are common payment and shipping terms?

Typical arrangements include 30% T/T advance payment with balance before shipment. Escrow and LC payments are accepted by established suppliers. FOB terms are standard; CIF can be arranged upon request. Sea freight is recommended for complete machines, while air shipping applies only to spare parts or accessories.