Pressure Sensors Used In Industries

Top sponsor listing

Top sponsor listing

About pressure sensors used in industries

Where to Find Pressure Sensors Suppliers for Industrial Applications?

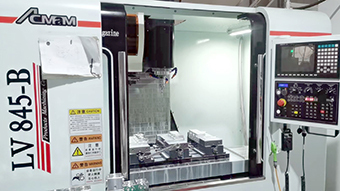

China remains a dominant hub for industrial pressure sensor manufacturing, with key supplier clusters in Guangdong, Hunan, and Beijing offering specialized production ecosystems. Dongguan and Shenzhen in Guangdong province host advanced electronics manufacturers leveraging localized supply chains for sensors, PCBs, and signal processing components, enabling rapid prototyping and scalable output. Changsha in Hunan benefits from automation industry integration, focusing on transmitters and measurement systems for industrial process control. Beijing-based suppliers emphasize precision instrumentation, often serving high-reliability sectors such as energy, aerospace, and environmental monitoring.

These regional hubs provide access to vertically integrated production networks—spanning silicon sensing elements, packaging, calibration, and final assembly—within tightly coordinated industrial zones. Buyers benefit from reduced component lead times, flexible MOQs (as low as 1 piece), and competitive pricing driven by mature manufacturing competition. Average lead times range from 7–15 days for standard models, with customization options available across materials, output signals, pressure ranges, and enclosure designs. Export-ready infrastructure ensures compliance with international shipping standards and global delivery within 10–20 days via express logistics.

How to Choose Industrial Pressure Sensor Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical & Product Alignment

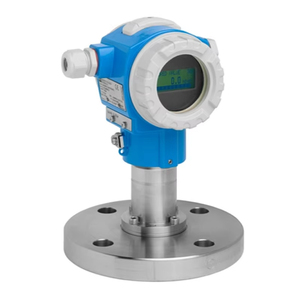

Confirm supplier expertise in core sensor types: piezoresistive, capacitive, strain gauge, or MEMS-based technologies. Evaluate compatibility with industrial requirements including pressure ranges (vacuum to 10,000 psi), output signals (4–20mA, 0–5V, I²C), media compatibility (gas, liquid, corrosive fluids), and environmental resilience (IP65+ ratings, thermal compensation). Prioritize suppliers listing specific OEM brands (e.g., Honeywell, TE Connectivity, IFM) as indicators of technical capability and component traceability.

Quality Assurance & Compliance

While formal certifications (ISO 9001, CE, RoHS) are not explicitly stated in available data, performance metrics serve as proxies for quality management. Target suppliers with on-time delivery rates exceeding 95% and response times under 2 hours. High reorder rates (>20%) suggest customer satisfaction and product reliability. For regulated industries, request material declarations, calibration certificates, and test reports prior to procurement.

Production and Customization Capacity

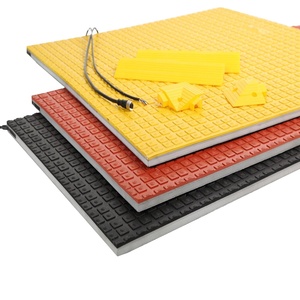

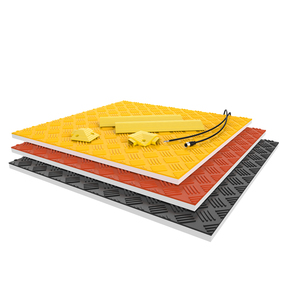

Assess flexibility through customization tags such as:

– Material selection (stainless steel, ceramic, silicon)

– Output protocol support (analog, digital, Modbus)

– Dimensional and mechanical design adjustments

– Labeling, packaging, and branding options

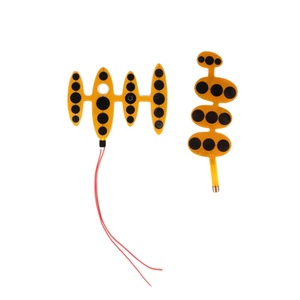

Verified manufacturers offer engineering support for tailored configurations, including custom wiring, membrane switches, and panel integration. Minimum order quantities typically start at 1 unit for stock items, increasing to 5+ units for calibrated or configured models.

Transaction Reliability Indicators

Use verifiable performance data to mitigate sourcing risk:

- On-time delivery ≥94%

- Response time ≤3 hours

- Reorder rate >15%

- Online transaction volume exceeding US $100,000 annually

Cross-reference product listings with detailed specifications, pricing consistency, and multi-product diversity to identify established operators versus trading intermediaries.

What Are the Leading Industrial Pressure Sensor Suppliers?

| Company Name | Main Products | On-Time Delivery | Response Time | Reorder Rate | Annual Online Revenue | Customization Support | Verification Status |

|---|---|---|---|---|---|---|---|

| Dongguan Soushine Industry Co., Ltd. | Pressure Sensors, Keypads, Load Cells, Auto Sensors | 94% | ≤3h | 22% | US $60,000+ | Yes (material, size, cable, logo, output) | Custom Manufacturer |

| Shenzhen Jinhuigu Technology Development Co., Ltd. | Pressure Sensors, Current Sensors, Flow Sensors | 100% | ≤2h | 20% | US $110,000+ | Limited (based on listed models) | Multispecialty Supplier |

| Changsha Luosen Automation Technology Co., Ltd. | Pressure Transmitters, Level Instruments, Temperature Gauges | 83% | ≤2h | 18% | US $160,000+ | No explicit mention | Multispecialty Supplier |

| Beijing Universe Technologies Co., Ltd. | Pressure Sensors, Position Sensors, Test Instruments | 92% | ≤2h | <15% | US $9,000+ | No explicit mention | Multispecialty Supplier |

| Hainan World Electronic Science and Techology Co., Ltd. | Automotive & Industrial Pressure Sensors | 100% | ≤1h | <15% | US $9,000+ | Yes (color, material, size, logo, packaging) | Multispecialty Supplier |

Performance Analysis

Dongguan Soushine stands out as a dedicated custom manufacturer with balanced performance metrics, strong reorder activity (22%), and comprehensive customization capabilities—ideal for OEM integration and private labeling. Shenzhen Jinhuigu leads in reliability (100% on-time delivery) and sales volume, supporting buyers seeking high-volume procurement of branded industrial sensors from recognized vendors like Honeywell and TE Connectivity. Changsha Luosen records the highest annual revenue, indicating robust export throughput in transmitter-based solutions despite a lower on-time delivery rate (83%), warranting closer logistics scrutiny. Hainan World excels in responsiveness (≤1h) and fulfillment accuracy but serves a narrower transaction base. Beijing Universe offers niche instrumentation expertise but shows limited repeat buyer engagement, suggesting potential gaps in long-term service or technical alignment.

FAQs

How to verify industrial pressure sensor supplier credibility?

Analyze on-time delivery history, reorder rate, and response speed as behavioral proxies for reliability. Request product datasheets, calibration documentation, and material compliance statements. For critical applications, conduct virtual factory audits to assess production lines, testing procedures, and inventory management practices.

What is the typical lead time for pressure sensor orders?

Standard products ship within 7–10 days. Customized units require 10–20 days depending on design complexity and testing requirements. Express shipping adds 3–7 days for international delivery.

Can suppliers provide samples for validation?

Yes, most suppliers offer sample units with minimum order quantities starting at 1 piece. Sample costs vary by model, typically ranging from $15–$640 for industrial-grade sensors. Some may credit sample fees toward bulk orders.

Are pressure sensors compliant with international standards?

Compliance is not explicitly documented in supplier profiles. Buyers must proactively request evidence of adherence to IEC, ISO, or ATEX standards where applicable. Verify ingress protection (IP), EMC, and temperature class ratings based on deployment environment.

What customization options are commonly available?

Suppliers support modifications in pressure range, electrical output, connector type, cable length, housing material, mounting configuration, and labeling. Full OEM redesigns—including custom membranes, digital interfaces, and multi-sensor modules—are feasible with verified manufacturers offering engineering collaboration.