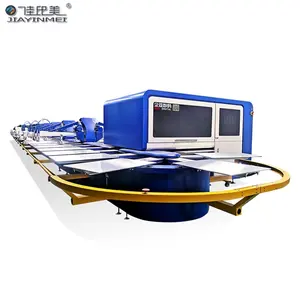

Print Machinery

Top sponsor listing

Top sponsor listing

1/9

1/9

1/44

1/44

1/9

1/9

1/2

1/2

0

0

0

0

1/30

1/30

1/1

1/1

1/35

1/35

1/18

1/18

1/3

1/3

0

0

1/11

1/11

About print machinery

Where to Find Print Machinery Suppliers?

China remains the global epicenter for print machinery manufacturing, with key industrial clusters in Zhejiang, Guangdong, and Henan provinces driving innovation and scale. Zhejiang specializes in high-precision flexographic and paper processing systems, supported by mature supply chains for rollers, printing plates, and automation components. Guangdong’s Pearl River Delta region focuses on digital textile, UV DTF, and direct-to-garment (DTG) printers, leveraging proximity to electronics and inkjet printhead suppliers. Henan has emerged as a hub for large-format roll-to-roll and eco-solvent printing solutions, benefiting from lower production costs and integrated mechanical engineering ecosystems.

These regional clusters enable vertical integration across casting, CNC machining, assembly, and software integration, reducing component lead times by 20–35%. Suppliers within these zones typically operate within tightly connected networks of material providers, control system integrators, and logistics partners, ensuring rapid prototyping and fulfillment. Buyers benefit from average production lead times of 15–30 days for standard units, with customization capabilities spanning print width (up to 3.2m), printhead configuration (Epson XP600, industrial piezoelectric), and software compatibility (bidirectional printing, automatic film feeding, UV varnish integration).

How to Choose Print Machinery Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

Confirm equipment specifications align with intended applications—such as fabric vs. rigid substrate compatibility, DPI requirements (up to 1440 × 1440), and ink system type (aqueous, solvent, UV-curable). For digital textile and DTF systems, verify inclusion of auxiliary components: powder shakers, curing ovens, heat presses, and RIP software. Ensure suppliers support printhead brands commonly used in your region for easier maintenance and consumables sourcing.

Production Infrastructure Assessment

Evaluate supplier capacity through measurable indicators:

- Minimum factory area exceeding 2,000m² for sustained output

- In-house R&D teams capable of firmware updates and interface customization

- Integrated testing lines for print accuracy, color calibration, and long-duration operation

Cross-reference online revenue data and reorder rates (e.g., >30% indicates strong customer retention) with response time (target ≤2 hours) to assess service reliability.

Quality & Transaction Assurance

Prioritize suppliers demonstrating compliance with international standards such as CE or ISO 9001, particularly for exports to EU and North American markets. Validate quality control processes through product inspection reports and video evidence of final testing. Utilize secure payment mechanisms where available, especially for first-time transactions. Conduct sample testing to evaluate print consistency, software stability, and material handling performance before full-scale orders.

What Are the Best Print Machinery Suppliers?

| Company Name | Main Products | On-Time Delivery | Response Time | Reorder Rate | Online Revenue (USD) | Customization Options | Key Features |

|---|---|---|---|---|---|---|---|

| Zhejiang Greenprint Machinery Co., Ltd. | Flexographic Printers, Paper Processing Machinery | 100% | ≤3h | - | $9,000+ | Limited | High uptime, stable delivery performance |

| Guangzhou Haolike Technology Co., Ltd. | DTF Printers, UV DTF Systems, Desktop Printers | 95% | ≤4h | 25% | $560,000+ | Extensive | High-speed printing, automatic cleaning, software integration, microwave-safe outputs |

| Fujian Xinhong Mech&elec Co., Ltd. | Heat Transfer Presses, T-shirt Printing Machines | 98% | ≤2h | <15% | $740,000+ | Moderate | Dual-platen electric systems, swing-away designs, wide format (40x50cm) |

| Henan Tiffan Machinery Co., Ltd. | Roll-to-Roll Printers, Eco-Solvent Machines, UV DTF | 96% | ≤2h | 38% | $550,000+ | High | Epson XP600 heads, double-station setups, lamination support, canvas/fabric compatibility |

| Changsha Deliou Technology Development Co., Ltd. | Semi-Automatic Screen Printers, T-shirt Printers | 98% | ≤1h | <15% | $120,000+ | Moderate | Single-color curved surface printing, compact design, fast response |

Performance Analysis

Guangzhou Haolike and Henan Tiffan demonstrate strong market traction with reorder rates of 25% and 38%, respectively, indicating robust customer satisfaction in the digital textile segment. Henan Tiffan stands out for its comprehensive customization scope—including printhead type, ink compatibility, and dual-station configurations—making it suitable for buyers seeking scalable production systems. Fujian Xinhong leads in responsiveness and delivery consistency (98%), backed by significant online revenue, suggesting established export operations. Zhejiang Greenprint maintains perfect on-time delivery but offers limited customization, positioning it as a reliable source for standardized paper-based printing lines. Changsha Deliou excels in communication speed (≤1h response), ideal for time-sensitive procurement cycles despite lower reorder metrics.

FAQs

How to verify print machinery supplier reliability?

Validate certifications (CE, ISO) through official registries and request documentation of internal quality checks, including print head alignment tests and software diagnostics. Analyze transaction history, focusing on consistent on-time delivery (>95%) and post-sale support availability. Request facility videos showing active production lines and inventory management practices.

What is the typical minimum order quantity (MOQ)?

Most suppliers list MOQs at 1 set or piece, enabling low-volume trials. Bulk pricing typically applies at 5+ units. Some manufacturers may adjust MOQ based on machine complexity or customization level.

Do suppliers offer customization options?

Yes, leading suppliers provide configurable options including print width (1.8–3.2m), printhead selection (Epson, Ricoh, Kyocera), ink type (eco-solvent, UV, aqueous), and integrated finishing systems (laminators, powder shakers, heat presses). Software features such as bidirectional printing, automatic nozzle cleaning, and graphic distortion correction are also customizable.

What are common lead times for print machinery?

Standard machines ship within 15–25 days after order confirmation. Customized systems require 30–45 days depending on technical modifications. Air freight delivery adds 7–10 days internationally; sea freight ranges from 25–40 days based on destination port.

Can suppliers provide samples or test runs?

Many suppliers offer printed sample kits upon request, often included with machine purchases. For digital textile systems, sample garments or substrate prints can be produced pre-shipment. Video demonstrations of live printing are increasingly common to validate performance before dispatch.