Print Machine

Top sponsor listing

Top sponsor listing

1/9

1/9

1/3

1/3

1/17

1/17

1/13

1/13

1/3

1/3

1/10

1/10

0

0

1/3

1/3

1/3

1/3

1/18

1/18

1/36

1/36

1/11

1/11

About print machine

Where to Find Print Machine Suppliers?

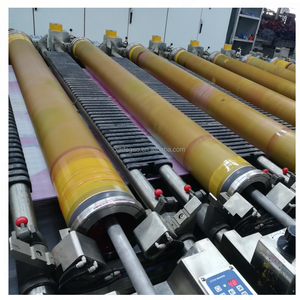

China remains the central hub for print machine manufacturing, with specialized production clusters in Zhejiang, Guangdong, and Shenzhen driving innovation and cost efficiency. Zhejiang’s Ruian City hosts a concentrated cluster of flexographic and digital printing machinery producers, supported by mature paper processing ecosystems and automated component supply chains. Guangdong, particularly Guangzhou, has emerged as a center for DTF (Direct-to-Film) and UV inkjet printer development, leveraging proximity to polymer material suppliers and export logistics networks at the Port of Nansha.

These industrial zones enable vertically integrated production—spanning print head assembly, software integration, and final testing—within compact geographic radii. This integration reduces lead times for standard units to 15–25 days and supports rapid prototyping for customized configurations. Buyers benefit from scalable output, localized sourcing of critical components (e.g., piezoelectric print heads, white ink circulation systems), and competitive pricing driven by 20–30% lower operational costs compared to Western or Southeast Asian manufacturers.

How to Choose Print Machine Suppliers?

Procurement decisions should be guided by verified performance metrics and technical capabilities:

Technical & Functional Validation

Confirm compatibility with intended applications—such as textile printing, label production, or industrial marking—by evaluating supported materials (fabric, PET film, rigid substrates), ink types (aqueous, solvent, UV-curable), and resolution capacity (measured in DPI). For DTF and UV printers, verify inclusion of essential subsystems: automatic ink recirculation, bidirectional printing calibration, heating/drying modules, and software integration with design platforms.

Production Capacity and Customization

Assess supplier infrastructure based on:

- Facility scale indicated by online revenue exceeding US $500,000/year as a proxy for operational volume

- Demonstrated customization options: color variants, film roll length adjustments, language localization, software packaging, and OEM branding

- In-house R&D capability evidenced by product iteration frequency and system upgrades (e.g., enhanced cleaning cycles, smart diagnostics)

Cross-reference response time (target ≤3 hours) and on-time delivery rates (ideal ≥98%) as indicators of order management reliability.

Transaction and Quality Assurance

Prioritize suppliers with documented quality control processes. While formal certifications (ISO 9001, CE, RoHS) are not explicitly stated in available data, evaluate compliance indirectly through:

- Reorder rates above 25% indicating customer retention and product reliability

- Comprehensive after-sales support elements: video tutorials, cleaning kits, consumables supply, and technical troubleshooting

- Use of industrial-grade components such as high-speed print heads and double-layer heating systems

Implement transaction safeguards including staged payments and pre-shipment inspections. Request functional videos or live demonstrations prior to bulk ordering.

What Are the Best Print Machine Suppliers?

| Company Name | Main Products | Online Revenue | On-Time Delivery | Response Time | Reorder Rate | Customization Options | Key Features |

|---|---|---|---|---|---|---|---|

| Zhejiang Greenprint Machinery Co., Ltd. | Flexographic Printers, Paper Processing Machinery | US $9,000+ | 100% | ≤3h | - | Limited | High uptime, core industrial machinery |

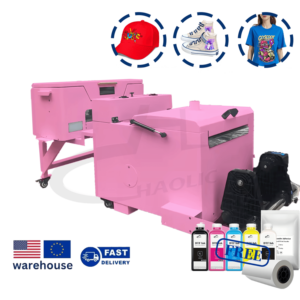

| Guangzhou Haolike Technology Co., Ltd. | DTF Printers, UV Printers, Heat Press Systems | US $560,000+ | 95% | ≤4h | 24% | Extensive | Multi-color printing, software integration, high DPI, automatic cleaning, consumables included |

| Shenzhen Chuang Cheng Da Technology Co., Ltd. | DTF Printers, Desktop Inkjet Systems | US $1,200,000+ | 98% | ≤2h | 25% | Moderate | White ink circulation, flash drying, oversized printing, smart functions |

| Shenzhen Chuangchengda Precision Manufacturing Co., Ltd. | DTF Printers, A3/A1 Digital Systems | US $600,000+ | 99% | ≤1h | 21% | High | Automated cleaning, dual-color resolution, upgraded control systems, waterproof printing |

| Jiangsu Heyme Supply Chain Management Co., Ltd. | DTF Printers, Inkjet Systems, Printing Inks | US $370,000+ | 99% | ≤3h | 46% | System-level customization | Cadlink software integration, commercial-grade output, all-in-one solutions |

Performance Analysis

Jiangsu Heyme stands out with a 46% reorder rate—the highest among peers—indicating strong customer satisfaction and reliable system performance, despite moderate response speed. Guangzhou Haolike offers the broadest range of technical features, including UV curing, emboss printing, and microwave-safe outputs, making it suitable for specialty applications. Shenzhen-based suppliers demonstrate superior responsiveness, with Chuangchengda achieving sub-1-hour average replies and 99% on-time fulfillment, ideal for time-sensitive procurement. Zhejiang Greenprint, while lacking reorder metrics, maintains perfect delivery performance, suggesting stable operations focused on industrial clients. Buyers seeking fully integrated DTF production lines should prioritize suppliers offering matching heat presses, ink sets, and software packages.

FAQs

How to verify print machine supplier reliability?

Evaluate on-time delivery records (target ≥98%), reorder rates (≥25% preferred), and response times (≤3 hours). Request evidence of system testing, software compatibility checks, and component sourcing practices. Verify inclusion of technical support resources such as user manuals, video guides, and remote diagnostics.

What is the typical lead time for print machines?

Standard desktop and A3 models are typically shipped within 15–20 days after order confirmation. Larger or customized units (e.g., A1 format, multi-station setups) may require 25–35 days for assembly and quality testing. Air freight adds 5–10 days for international delivery.

Do suppliers support customization?

Yes, most suppliers offer customization in color, logo branding, software interface language, film roll dimensions, and packaging. High-end models include configurable ink capacity, heating systems, and graphic processing parameters. Confirm feasibility and potential MOQ adjustments before finalizing specifications.

What are common minimum order quantities (MOQ)?

The standard MOQ for print machines is 1 set or piece, facilitating low-volume trials and startup procurement. Bulk discounts typically apply from 5 units onward. Consumables and spare parts may have separate MOQs based on supplier policy.

Are samples available for testing?

Sample availability varies. Some suppliers provide test prints or demo units upon request, often refundable against future orders. Full-machine samples may incur partial charges, especially for high-end configurations. Clarify return policies and shipping responsibilities in advance.