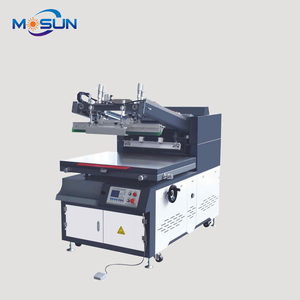

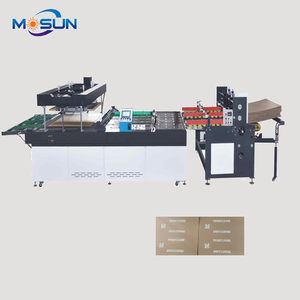

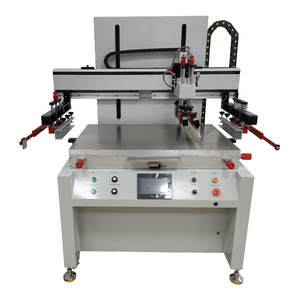

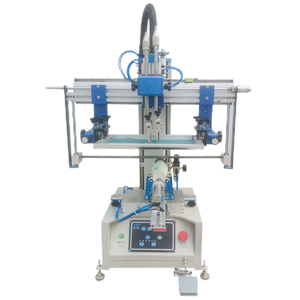

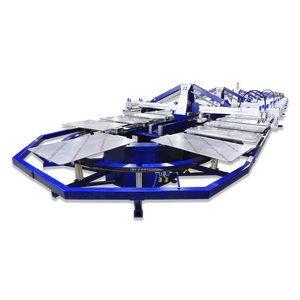

Printing Screen Machine

Top sponsor listing

Top sponsor listing

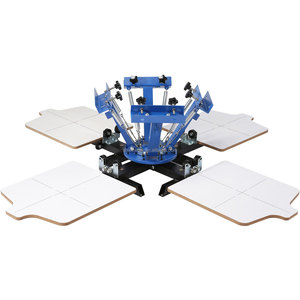

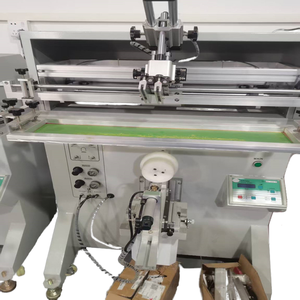

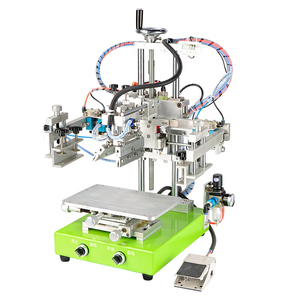

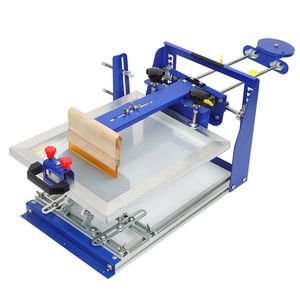

About printing screen machine

Where to Find Printing Screen Machine Suppliers?

China remains the global epicenter for printing screen machine manufacturing, with key industrial clusters concentrated in Hebei, Shijiazhuang, Ruian, and Dongguan. These regions host vertically integrated supply chains encompassing precision machining, motor control systems, UV curing components, and automated printing stations. Hebei and Shijiazhuang specialize in manual and semi-automatic screen printers, supported by localized networks of coater units, squeegee manufacturers, and exposure frame suppliers. Coastal hubs like Ruian and Dongguan focus on higher-end desktop, flatbed, and fully automatic rotary models, leveraging proximity to export ports and advanced electromechanical component sourcing.

The clustering effect enables streamlined production cycles, with many suppliers operating end-to-end facilities that include CNC fabrication, servo motor integration, and final assembly under one roof. This infrastructure supports rapid prototyping, scalable batch production, and customization of critical parameters such as printing area, track size, mesh tension, and ink delivery systems. Buyers benefit from lead times averaging 15–30 days for standard configurations, while localized material sourcing reduces costs by 20–35% compared to non-Asian manufacturers. The ecosystem also facilitates multi-station color registration, fine-detail printing, and compatibility with solvent-based, water-based, and UV-curable inks.

How to Choose Printing Screen Machine Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

Confirm compatibility with required substrates (textiles, plastics, glass, electronics) and printing specifications such as micro-registration accuracy, flash drying integration, and multi-color station alignment. Suppliers should provide detailed technical documentation covering motor control systems, belt precision, frame clamping mechanisms, and exposure unit specifications (UV or LED). For high-resolution applications, verify support for polyurethane seals, fine mesh screens, and automated arm positioning.

Production Capacity Assessment

Evaluate core metrics to ensure scalability:

- Facility specialization indicated by product listing distribution (e.g., >400 screen printer listings suggest dedicated focus)

- In-house engineering support for mold design, graphic alignment, and custom track modifications

- Customization scope including squeegee speed, printing width, dryer tunnel integration, and laser locator installation

Cross-reference response time (target ≤2 hours) and on-time delivery rate (preferably >90%) as indicators of operational efficiency.

Quality & Transaction Assurance

Prioritize suppliers demonstrating consistent reorder rates (>20%) and verified performance histories. While formal certifications (ISO, CE) are not explicitly stated in available data, insist on compliance verification during due diligence. Utilize secure payment methods with milestone-based releases and request sample testing to validate print precision, frame stability, and long-term durability. Review packaging standards and labeling practices to prevent transit damage, especially for servo-driven or double-side clamp models.

What Are the Best Printing Screen Machine Suppliers?

| Company Name | Location | Main Products (Listings) | On-Time Delivery | Reorder Rate | Avg. Response | Online Revenue | Customization Support |

|---|---|---|---|---|---|---|---|

| Hebei Doyan Screen Printing Equipment Co., Ltd. | Hebei, CN | Screen Printers (457) | 83% | 15% | ≤2h | US $380,000+ | Yes (exposure size, ink type, frame, dryer) |

| Shijiazhuang Xiangsheng Screen Printing Equipment Co., Ltd. | Shijiazhuang, CN | Screen Printers (85) | 100% | <15% | ≤5h | US $20,000+ | Limited (standard models emphasized) |

| Ruian Chengyue Electromechanical Co., Ltd. | Ruian, CN | Heat Press Machine (367), Screen Printers (44) | 94% | 20% | ≤2h | US $130,000+ | Moderate (frame height, station count) |

| Dongguan Heng Lin Printing Machinery And Equipment Co., Ltd. | Dongguan, CN | Screen Printers (127) | 75% | <15% | ≤5h | US $10,000+ | Yes (curved surface, desktop models) |

| Dongguan Xinze Printing Machinery Co., Ltd. | Dongguan, CN | Screen Printers (custom-focused) | 50% | 33% | ≤2h | US $900+ | High (color, material, size, registration) |

Performance Analysis

Hebei Doyan leads in scale and product depth, offering extensive customization and the highest online revenue, though its 83% on-time delivery suggests room for logistics improvement. Shijiazhuang Xiangsheng stands out with perfect on-time performance but lower reorder activity, indicating potential gaps in post-sale satisfaction or niche market positioning. Ruian Chengyue demonstrates balanced performance with a 20% reorder rate and strong responsiveness, reflecting reliable service despite secondary focus on screen printers. Dongguan Heng Lin offers specialized desktop and curved-surface machines but lags in delivery consistency. Dongguan Xinze, despite low revenue and delivery performance, reports a high 33% reorder rate, suggesting strong customer retention likely driven by deep customization capabilities for complex applications such as multi-color automatic registration and vertical flatbed printing.

FAQs

How to verify printing screen machine supplier reliability?

Assess on-time delivery history, response time consistency, and reorder rate as proxies for reliability. Request technical drawings, motor specifications, and material compatibility charts. Conduct virtual factory audits to confirm in-house production capabilities for critical components like squeegee systems, UV coaters, and registration guides.

What is the typical MOQ and pricing range?

Minimum Order Quantity is typically 1 unit for standalone machines, with bulk discounts starting at 5+ units. Prices range from $50 for basic manual kits to $17,800 for fully automatic 8-station rotary systems. Desktop and semi-automatic models average $700–$1,250.

What customization options are commonly available?

Suppliers offer adjustments in printing width, number of color stations, frame clamping mechanism, drying system (flash or tunnel), exposure unit (UV/LED), and squeegee pressure/speed controls. Advanced options include micro-registration, automatic arms, solvent-resistant seals, and laser alignment systems.

What are standard lead times and shipping options?

Lead times range from 10–25 days for standard orders, extending to 35 days for customized configurations. Sea freight is optimal for container loads, while air shipping is viable for single units requiring rapid deployment. Confirm packaging robustness for sensitive components like servo motors and control panels.

Do suppliers provide technical support and after-sales service?

Support levels vary. Top-tier suppliers offer operation manuals, setup videos, and remote troubleshooting. For continuous production environments, negotiate service-level agreements covering spare parts availability, software updates, and on-site maintenance access.