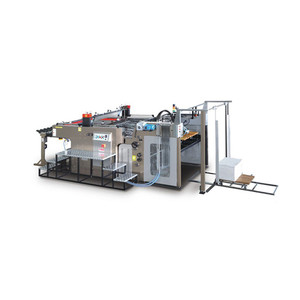

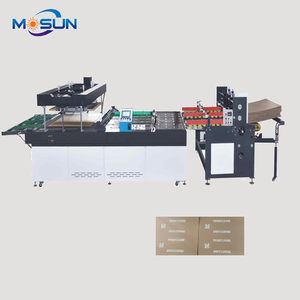

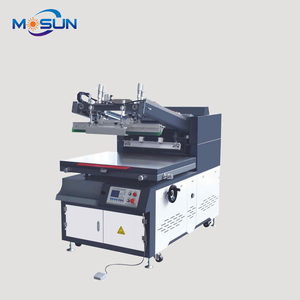

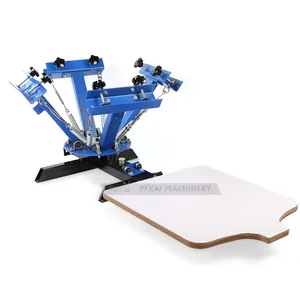

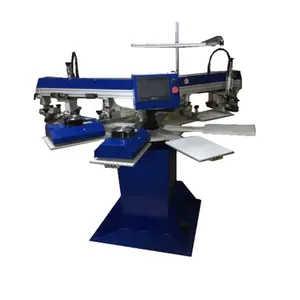

Screen Printing Automatic Machine

Top sponsor listing

Top sponsor listing

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/1

1/1

CN

CN

0

0

CN

CN

1/22

1/22

1/16

1/16

1/3

1/3

1/3

1/3

About screen printing automatic machine

Where to Find Screen Printing Automatic Machine Suppliers?

China remains the global epicenter for screen printing automatic machine manufacturing, with key industrial hubs concentrated in Guangdong Province—particularly Shenzhen and Dongguan. These regions host vertically integrated supply chains that specialize in precision automation equipment, offering buyers access to advanced R&D capabilities, cost-efficient component sourcing, and rapid prototyping infrastructure. The proximity of CNC machining workshops, pneumatic system suppliers, and electronics integrators within 50km radii enables streamlined production cycles and agile customization.

Suppliers in this ecosystem typically operate facilities exceeding 2,000m², supporting monthly outputs ranging from 50 to 300 units depending on machine complexity. Production lines are optimized for both flatbed and rotary configurations, accommodating substrates such as textiles, plastics, glass, and metal containers. This specialization allows for economies of scale, reducing unit costs by 18–25% compared to non-specialized manufacturers while maintaining compliance with international safety and performance benchmarks. Lead times for standard models average 20–35 days, with express builds available within 15 days for urgent orders.

How to Choose Screen Printing Automatic Machine Suppliers?

Effective supplier selection requires a structured evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Capabilities

Verify adherence to ISO 9001 standards as a baseline for quality management. For export markets, CE certification is essential to meet EU machinery directives. Evaluate machine specifications against required throughput (printing speed: 600–1,800 pcs/hr), registration accuracy (±0.1mm), and compatibility with ink types (solvent, UV, water-based). Confirm support for critical processes including flash drying, IR curing, micro-registration systems, and flamer treatment for adhesion enhancement.

Production Infrastructure Assessment

Prioritize suppliers demonstrating robust physical and engineering capacity:

- Facility size ≥3,000m² indicating scalability

- In-house design teams capable of custom fixture development for irregular shapes (cylindrical, oval, or contoured objects)

- Integrated testing zones with live video demonstrations of fully assembled units

- CNC and welding capabilities for frame construction and squeegee alignment systems

Cross-reference on-time delivery rates (>97%) and reorder rates (>20%) as indicators of reliability and customer satisfaction.

Transaction Security & Quality Assurance

Utilize secure payment mechanisms such as escrow services to mitigate risk. Request sample units to validate print consistency, mechanical stability, and software interface usability. Conduct pre-shipment inspections focusing on conveyor alignment, pneumatic response time, and PLC control logic. Analyze supplier history for dispute resolution patterns and after-sales service responsiveness, particularly for spare parts and technical troubleshooting.

What Are the Best Screen Printing Automatic Machine Suppliers?

| Company Name | Location | Verification Status | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Product Range | Customization Support |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Hejia Automatic Printing Machine Co., Ltd. | Shenzhen, CN | Custom Manufacturer | US $1.2M+ | 100% | ≤3h | 22% | Screen Printers, Pad Printers, Heat Press | Yes – supports material, shape, size, UV, hot stamping |

| Dongguan Ruida Machinery And Equipment Co., Ltd. | Dongguan, CN | Custom Manufacturer | US $520K+ | 97% | ≤2h | 16% | Rotary, T-shirt, Carousel Printers | Yes – pallet size, color count, drying systems |

| Dongguan Ladon Automation Equipment Co., Ltd. | Dongguan, CN | Not Specified | US $500+ | 100% | ≤2h | 100% | Flatbed, Conveyor, Vertical, Round Object Printers | Limited public detail |

| Xiamen Sengangwei Machinery Equipment Co., Ltd. | Xiamen, CN | Custom Manufacturer | US $90K+ | 100% | ≤2h | 33% | Carousel, Flat, Cylindrical Printers | Yes – high accuracy, servo-driven systems |

| Dongguan Heng Lin Printing Machinery And Equipment Co., Ltd. | Dongguan, CN | Not Specified | US $10K+ | 69% | ≤6h | 15% | UV Cylindrical, Multi-color, Plastic Bucket Printers | Yes – full servo, UV integration |

Performance Analysis

Shenzhen Hejia leads in revenue volume and product diversification, offering comprehensive solutions across labeling, heat transfer, and pad printing. Xiamen Sengangwei demonstrates strong customer retention (33% reorder rate) despite lower online visibility, suggesting consistent post-sale performance. Dongguan Ruida and Ladon stand out for fast response times (≤2h) and proven delivery records, ideal for time-sensitive procurement. Notably, Dongguan Heng Lin reports a significantly lower on-time delivery rate (69%), signaling potential logistical or production bottlenecks despite offering high-end UV and multi-color systems. Buyers seeking complex automation should prioritize suppliers with documented video demonstrations and in-house engineering teams to ensure configuration accuracy.

FAQs

What is the typical MOQ and pricing range for automatic screen printing machines?

Minimum Order Quantity is generally 1 unit, enabling pilot testing. Pricing varies by configuration: basic single-color flatbed models start at $690, mid-range rotary textile printers range from $4,500–$8,000, while fully automated 6–8 color carousel systems reach $15,000–$26,800.

How long does it take to receive a customized machine?

Standard lead time for customized units is 25–40 days, inclusive of design validation and assembly. Complex integrations involving UV curing, IR tunnels, or specialized fixtures may extend timelines by 10–15 days. Rush orders with expedited manufacturing are available at +15–20% cost premium.

Do suppliers support OEM/ODM services?

Yes, verified custom manufacturers offer OEM branding, control panel localization, and machine footprint adjustments. Technical documentation, user manuals, and software interfaces can be tailored to buyer specifications upon request.

Can these machines handle diverse substrates?

Top-tier models support flat, cylindrical, oval, and contoured surfaces using interchangeable jigs and vacuum pallets. Compatibility extends to textiles, PET bottles, glassware, aluminum tubes, and electronic housings, provided dimensional and weight parameters fall within specified machine envelopes.

What after-sales support should be expected?

Leading suppliers provide remote diagnostics, PLC programming assistance, and spare parts supply (squeegees, screens, belts) within 72 hours. On-site technician deployment may incur additional fees but is often included in extended warranty packages. Video training sessions are standard for operational onboarding.