Product Prototype Maker

CN

CN

About product prototype maker

Where to Find Product Prototype Maker Suppliers?

China leads global prototype manufacturing with concentrated supplier clusters in Guangdong and Jiangxi provinces, offering advanced capabilities in rapid prototyping technologies. Shenzhen and Dongguan in Guangdong host over 70% of high-precision CNC machining and 3D printing service providers, leveraging integrated electronics and hardware ecosystems. Ganzhou in Jiangxi has emerged as a cost-competitive hub for small-batch plastic and metal prototyping, supported by regional e-commerce logistics networks.

These industrial zones feature vertically aligned supply chains—spanning material sourcing, precision machining, surface treatment, and assembly—enabling lead times as short as 5–7 days for simple prototypes. Buyers benefit from localized access to multi-axis CNC machines, SLA/SLS 3D printers, vacuum casting systems, and post-processing facilities within 30km radii. Key advantages include MOQs as low as 1 piece, 25–40% lower unit costs compared to Western suppliers, and scalable transition from prototype to mass production.

How to Choose Product Prototype Maker Suppliers?

Adopt these evaluation criteria to ensure technical and operational reliability:

Technical Capability Verification

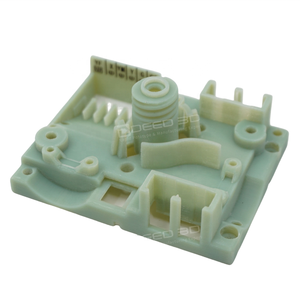

Confirm availability of core prototyping methods: CNC machining (3-axis to 5-axis), 3D printing (SLA, SLS, FDM, DLP), vacuum casting, and sheet metal forming. For functional prototypes, verify compatibility with engineering-grade materials such as ABS, PC, nylon, titanium, aluminum, and stainless steel (304, 316L). Prioritize suppliers offering CAD/CAM support, design feedback, and file conversion services.

Quality & Process Compliance

While ISO 9001 certification is not universally held among niche prototype makers, assess quality through measurable performance indicators:

- On-time delivery rate ≥98%

- Average response time ≤4 hours

- Reorder rate >35% indicating customer retention

- Video confirmation of sample production and inspection processes

Cross-reference stated capabilities with actual output via sample testing, focusing on dimensional accuracy (±0.05mm standard), surface finish options (bead blasting, anodizing, electroplating), and structural integrity for complex geometries.

Customization & Transaction Security

Ensure suppliers support full customization—from raw material selection to color matching (Pantone), engraving, labeling, and packaging. Require clear terms on intellectual property protection for proprietary designs. Use secure transaction platforms with escrow options to mitigate risk, especially for first-time engagements. Validate export experience through shipping records and compliance with destination-country regulations for electronic or automotive components.

What Are the Best Product Prototype Maker Suppliers?

| Company Name | Location | Verified Type | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Min. Order | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Perfect Precision Products Co., Ltd. | Guangdong, CN | Custom Manufacturer | US $1,700,000+ | 100% | ≤2h | 37% | 10 pcs | $0.55–5.08 |

| Guangzhou Gaojie Model Design And Manufacturing Co., Ltd. | Guangdong, CN | Custom Manufacturer | US $80,000+ | 96% | ≤4h | 51% | 1 pc | $0.15–2.50 |

| Yongkang Qucheng Technology Co., Ltd. | Zhejiang, CN | Custom Manufacturer | US $230,000+ | 99% | ≤2h | 37% | 1 pc | $1–10 |

| Dongguan HC-Mold Hardware Co., Ltd. | Guangdong, CN | Custom Manufacturer | US $610,000+ | 100% | ≤20h | 100% | 1 pc | $2–20 |

| Ganzhou Point Creation E-Commerce Co., Ltd. | Jiangxi, CN | - | US $4,000+ | 100% | ≤4h | - | 1 pc | $10–50 |

Performance Analysis

Shenzhen-based Shenzhen Perfect Precision Products excels in high-volume CNC and metal 3D printing with tight tolerances and multi-material processing, suitable for aerospace and medical applications. Guangzhou Gaojie offers the lowest MOQs and competitive pricing for transparent acrylic and silicone prototypes, ideal for consumer product development. Yongkang Qucheng provides balanced capabilities across resin, metal, and vacuum casting with strong customization depth, including plating and full-color printing.

Dongguan HC-Mold stands out with a 100% reorder rate, indicating exceptional client satisfaction, despite slower response times. Its strength lies in electronics and gear prototyping with electroplating and matte finishes. Ganzhou Point Creation serves budget-conscious buyers needing basic 3D-printed models, though higher per-unit pricing suggests limited economies of scale. Buyers should prioritize suppliers with documented engineering feedback loops, sample rooms, and rush-order capabilities for accelerated development cycles.

FAQs

How to verify a prototype maker’s technical capability?

Request machine specifications (e.g., 5-axis CNC, laser precision), supported file formats (STEP, IGES, STL), and material datasheets. Conduct video audits of workshop operations and review before/after images of finished prototypes. Confirm in-house post-processing capacity for deburring, polishing, painting, and assembly.

What is the typical lead time for custom prototypes?

Standard prototypes take 3–7 days depending on complexity. Rush orders with expedited processing can be completed in 48–72 hours. Add 3–5 days for international air shipping. Functional or large-scale prototypes (e.g., car shells) may require 10–14 days.

Can I get a free sample?

Free samples are rare; most suppliers charge a nominal fee covering material and labor. Fees may be waived upon placement of a follow-up production order. Sample costs typically range from $10–$50 depending on size and technology used.

Do prototype makers support IP protection?

Reputable manufacturers offer NDA agreements and secure handling of design files. Confirm data encryption practices and request deletion protocols post-project. Avoid sharing unprotected CAD files with unverified suppliers.

How to manage customization requests effectively?

Submit detailed specifications including material type, dimensions, color (Pantone code), surface finish, and functional requirements. Provide 3D models in native or neutral formats. Specify any required certifications (e.g., RoHS for electronics) and request digital renderings for approval before production.