Protected Distribution System

Top sponsor listing

Top sponsor listing

CN

CN

1/8

1/8

1/10

1/10

1/22

1/22

1/24

1/24

About protected distribution system

Where to Find Protected Distribution System Suppliers?

China remains a central hub for protected distribution system manufacturing, with key production clusters in Zhejiang and Henan provinces driving efficiency and specialization. Wenzhou, located in Zhejiang, hosts a dense network of electrical equipment manufacturers specializing in power distribution enclosures, offering vertically integrated production from sheet metal fabrication to final assembly. Henan’s industrial base complements this with expertise in heavy-duty aluminum busbar systems and fire-resistant cable management solutions, enabling cost-competitive production due to proximity to raw material suppliers.

These regional ecosystems support rapid prototyping and scalable output, with many suppliers operating facilities exceeding 5,000m² and maintaining in-house tooling, molding, and testing capabilities. Buyers benefit from localized supply chains that reduce component lead times by up to 30% compared to offshore alternatives. Standard order fulfillment typically ranges from 15–30 days, with bulk orders (10,000+ units) achievable within 45 days. The concentration of technical labor—particularly in Wenzhou’s low-voltage electrical sector—enables high customization rates while sustaining competitive pricing, especially for IP-rated enclosures and modular breaker configurations.

How to Choose Protected Distribution System Suppliers?

Procurement decisions should be guided by verified operational metrics and technical capability assessments:

Quality & Compliance Verification

Confirm adherence to international standards such as IEC 61439 (low-voltage switchgear), IP65/IP66 ratings for environmental protection, and RoHS compliance for material safety. While formal ISO 9001 certification is not explicitly stated in available data, prioritize suppliers demonstrating consistent on-time delivery (≥98%) and documented quality control processes. For export markets, CE marking or equivalent regulatory alignment is essential for customs clearance and end-user acceptance.

Production Capacity Evaluation

Assess scalability through measurable indicators:

- Minimum monthly output capacity of 10,000 units for plastic enclosures or 5,000 meters for busbar systems

- In-house processing capabilities including CNC punching, bending, powder coating, and ultrasonic sealing for waterproof variants

- Customization infrastructure supporting modifications in size, material (ABS, polycarbonate, aluminum, stainless steel), color, labeling, and internal component layout

Cross-reference response time (target ≤3 hours) and reorder rate (<15% indicates broad market reach) as proxies for operational responsiveness and customer satisfaction.

Transaction Risk Mitigation

Utilize secure payment structures such as escrow services to ensure product conformity before release of funds. Request samples to validate build quality, ingress protection, and terminal arrangement accuracy. Evaluate packaging integrity and labeling consistency during trial shipments. Prioritize suppliers with transparent online transaction histories, particularly those reporting verifiable revenue streams (e.g., US $10,000+ annual online sales) as an indicator of sustained commercial activity.

What Are the Best Protected Distribution System Suppliers?

| Company Name | Location | Verified Type | Main Products | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Wenzhou Zhongxin Electronic Technology Co., Ltd. | Zhejiang, CN | Custom Manufacturer | Power Distribution Equipment, Electronics Enclosures, Switches | 98% | ≤3h | <15% | US $10,000+ | Yes (boxes, connectors, color, material, size, logo, waterproof) |

| Foshan Jinbang Electric Co., Ltd. | Guangdong, CN | - | Power Distribution Equipment | 100% | ≤4h | <15% | Not specified | No explicit mention |

| Wenzhou Wannai Electric Co., Ltd. | Zhejiang, CN | - | Power Distribution Equipment, Enclosures, Switches | 92% | ≤1h | 33% | US $5,000+ | Limited indication |

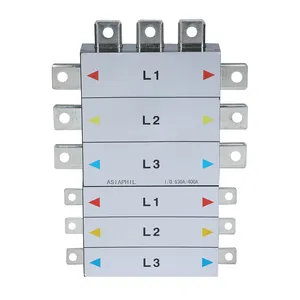

| Henan Zhongyu Yonghui Electric Co., Ltd. | Henan, CN | Multispecialty Supplier | Aluminum Busduct, Copper Busbar, Fire-Resistant Troughs | 100% | ≤1h | <15% | US $20,000+ | Yes (material, enclosure, length, conductor, tap-offs) |

| Wenzhou Beiyi Electric Co., Ltd. | Zhejiang, CN | - | MCB Boxes, Surge Protection, Voltage Regulators | 100% | ≤1h | 15% | US $20,000+ | No explicit mention |

Performance Analysis

Suppliers like Foshan Jinbang and Henan Zhongyu Yonghui achieve perfect on-time delivery records (100%), indicating strong production planning and logistics execution. Wenzhou-based manufacturers dominate customization agility, with Zhongxin offering extensive options across form, function, and branding. Henan Zhongyu stands out for high-value aluminum and copper busway systems, supported by robust online revenue (US $20,000+) and fast response times, making it suitable for engineered-to-order projects. Wenzhou Wannai's higher reorder rate (33%) suggests niche appeal, possibly due to specialized IP65/IP66-rated enclosures, though its lower on-time performance warrants closer shipment monitoring. For standardized plastic distribution boxes, Foshan Jinbang offers competitive pricing starting at $1.35/unit with minimal MOQs. In contrast, Henan Zhongyu targets industrial clients with meter-based busbar solutions priced between $99–$165/meter, requiring minimum 5-meter orders.

FAQs

How to verify protected distribution system supplier reliability?

Evaluate on-time delivery history, response speed, and transaction volume as proxies for operational stability. Request product test reports for dielectric strength, temperature rise, and ingress protection. Conduct virtual factory audits to confirm in-house manufacturing capabilities and quality inspection procedures.

What is the typical minimum order quantity (MOQ)?

MOQ varies by product type: plastic enclosures start as low as 1 piece (sample batches), while bulk orders begin at 10–200 pieces. Aluminum busbar systems typically require 5-meter minimums. High-volume buyers can negotiate MOQ reductions based on long-term contracts.

Do suppliers offer customization for protected distribution systems?

Yes, leading manufacturers support tailored designs in dimensions, materials (plastic, aluminum, steel), ingress protection levels, terminal arrangements, and branding. Wenzhou Zhongxin and Henan Zhongyu provide comprehensive modification options, including graphic labels and custom tap-off configurations.

What are common lead times for sample and bulk orders?

Sample production takes 7–15 days depending on complexity. Bulk production lead times range from 20–30 days for standard enclosures and up to 45 days for customized or large-scale busbar installations. Expedited delivery options exist for urgent requests.

Can suppliers handle international shipping and compliance?

Experienced exporters manage global logistics via air or sea freight and provide documentation for customs clearance. Ensure compatibility with destination-market electrical codes and request compliance declarations for CE, CB, or other relevant certifications where applicable.