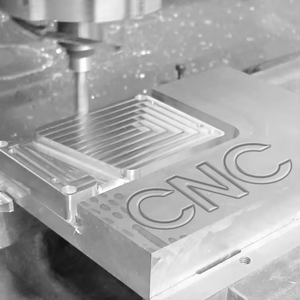

Prototype Cnc Services

Top sponsor listing

Top sponsor listing

CN

CN

CN

CN

About prototype cnc services

Where to Source Prototype CNC Services?

China remains the global hub for prototype CNC machining, with key manufacturing clusters in Zhejiang, Fujian, and Jiangsu provinces offering specialized capabilities. Ningbo and Xiamen host high-density networks of precision engineering firms that integrate rapid prototyping with low-volume production, enabling agile development cycles. These regions benefit from mature supply chains for raw materials—particularly aluminum, stainless steel, and engineering plastics—reducing material lead times by 20–30% compared to offshore alternatives.

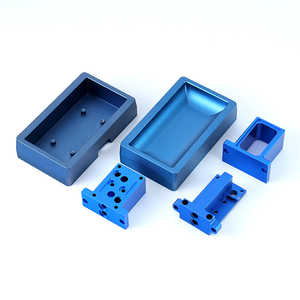

The industrial ecosystems support vertically integrated operations, where design, CNC milling, turning, wire cutting, and surface treatments (e.g., anodizing, color film coating) are managed under one roof. This integration allows for faster iteration, with typical prototype delivery windows ranging from 5–12 days depending on complexity. Buyers gain access to scalable capacity, localized quality control, and cost advantages driven by competitive labor rates and optimized logistics, achieving up to 40% savings over domestic Western suppliers for comparable tolerances (±0.005mm).

How to Evaluate Prototype CNC Service Providers?

Adopt a structured assessment framework when selecting suppliers:

Technical Capability Verification

Confirm availability of multi-axis CNC machining centers (3-axis, 4-axis, and 5-axis), Swiss-type lathes, and wire EDM equipment. Review supported materials—common options include aluminum alloys (6061, 7075), stainless steel (303, 316), brass, titanium, and plastics such as ABS and PEEK. Tolerance capability should be documented, with precision providers maintaining ±0.005mm or tighter.

Quality & Compliance Standards

Prioritize suppliers adhering to ISO 9001 quality management systems. For medical, aerospace, or automotive applications, validate compliance with AS9100, IATF 16949, or FDA guidelines. Request inspection reports including first-article inspection (FAI), CMM reports, and material certifications. Surface finish specifications (Ra values) and post-processing options (anodizing, plating, laser engraving) should align with project requirements.

Production & Responsiveness Metrics

Assess operational performance using verified benchmarks:

- On-time delivery rate ≥97%

- Average response time ≤4 hours

- Reorder rate >25% indicating customer retention

- Minimum order quantity (MOQ) flexibility: single-piece prototyping to batch runs

Cross-reference these metrics with actual transaction volume (e.g., online revenue indicators) to assess scalability and service consistency. Inquire about digital workflow integration—support for STEP, IGES, DWG, and 3D PDF files enhances collaboration efficiency.

Top Prototype CNC Service Suppliers

| Company Name | Verified Type | Main Products | Customization Options | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Min. Order Flexibility |

|---|---|---|---|---|---|---|---|---|

| Ningbo Baozhen Machinery Co., Ltd. | Custom Manufacturer | Machining Services | Color, material, size, logo, packaging, label, drawings, wire cutting, design | 100% | ≤2h | 24% | US $70,000+ | Not specified |

| Xiamen Yuling Intelligent Equipment Co., Ltd. | Custom Manufacturer | OEM Custom Aluminum Parts, High-Precision CNC Machining | Color, material, size, logo, packaging, label, graphic | 97% | ≤4h | 28% | US $60,000+ | 10 pieces |

| SkyReach Intelligent MFG Limited | Custom Manufacturer | Precision Metal Machining, Stainless Steel/Aluminum Turning | Color, material, size, logo, packaging, label, graphic | 83% | ≤4h | <15% | US $20,000+ | 1 piece |

| Kaiao Rapid Manufacturing Co.,limited | Custom Manufacturer | ABS Fabricated Components, Injection Molding, Prototyping | Color, material, size, logo, packaging, label, graphic | 100% | ≤3h | 100% | US $10,000+ | 10 pieces |

| Huzhou Dear Industry Co., Ltd. | Multispecialty Supplier | Rapid Prototype Machining, Anodized Aluminum Parts, OEM Services | Color, material, size, logo, packaging, label, hardness, EPDM, TPU, 3D drawings, injection | 97% | ≤7h | 53% | US $350,000+ | 1–2 pieces |

Performance Analysis

Huzhou Dear Industry stands out with the highest reported online revenue (US $350,000+) and a strong reorder rate of 53%, indicating consistent service satisfaction and broad market reach. The company supports ultra-low MOQs starting at one piece, ideal for early-stage prototyping. Kaiao Rapid Manufacturing achieves a perfect 100% reorder rate, reflecting exceptional client retention despite lower transaction volume, likely due to dedicated customization and responsive service (≤3h response). Ningbo Baozhen and Xiamen Yuling demonstrate reliable on-time delivery (100% and 97%) with fast communication, positioning them well for urgent or iterative development projects. SkyReach offers single-piece ordering but shows a lower reorder rate (<15%) and on-time delivery (83%), suggesting potential fulfillment risks. Buyers should verify production logs and conduct sample audits before scaling orders with such providers.

FAQs

What is the typical lead time for CNC prototypes?

Standard lead times range from 5 to 12 days, depending on part complexity, material availability, and finishing requirements. Expedited services may reduce this to 3–5 days with priority fees.

Do CNC service providers accept single-piece orders?

Yes, several suppliers—including SkyReach and Huzhou Dear Industry—support MOQs as low as one piece, making them suitable for initial concept validation and functional testing.

How are custom finishes and coatings applied?

Common surface treatments include anodizing (Type II and III), powder coating, passivation, and color film application. Suppliers with in-house capabilities ensure tighter process control and shorter turnaround versus outsourced finishing.

Can suppliers handle full product lifecycle support?

Leading providers offer end-to-end services from CAD modeling and DFM analysis to prototyping, small-batch production, and assembly. Confirm whether technical engineers are available for design optimization and tolerance review.

What payment and transaction safeguards are recommended?

Use secure payment methods with buyer protection. For larger contracts, consider milestone-based payments tied to prototype approval, pre-shipment inspection, and third-party quality verification to mitigate risk.