Prototype Machining Services

Top sponsor listing

Top sponsor listing

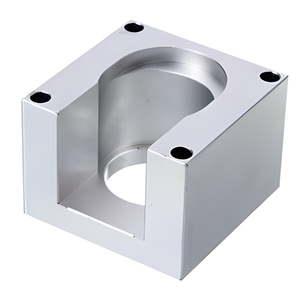

About prototype machining services

Where to Find Prototype Machining Services Suppliers?

Asia, particularly China and Vietnam, serves as the central hub for global prototype machining services, driven by concentrated industrial zones in Dongguan, Shenzhen, and northern Vietnam. These regions host vertically integrated manufacturing ecosystems that combine CNC machining, sheet metal fabrication, 3D printing, and vacuum casting under one supply chain. Dongguan and Shenzhen alone account for over 40% of high-precision rapid prototyping output in Southern China, supported by proximity to Tier-1 suppliers of raw materials and advanced metrology equipment.

The region’s infrastructure enables agile production cycles, with average lead times ranging from 5–12 days for machined prototypes depending on complexity. Localized tooling and material sourcing reduce per-unit costs by 20–35% compared to North American or European workshops. Buyers benefit from flexible MOQs—often as low as 1 piece—and seamless integration between digital design (CAD/CAM) and physical production. This ecosystem supports both functional testing prototypes and pre-series production runs with consistent tolerances down to ±0.005 mm.

How to Choose Prototype Machining Services Suppliers?

Effective supplier selection requires verification across technical, operational, and transactional dimensions:

Technical Capabilities

Confirm access to multi-axis CNC machining (including 5-axis), milling, turning, and secondary processes such as anodizing, plating, and laser engraving. Suppliers should support a wide range of engineering materials—including aluminum 6061/7075, stainless steel, brass, titanium, and engineering plastics like PEEK and ABS. For design-intensive applications, evaluate experience with rapid iteration workflows and compatibility with STL, STEP, and IGES file formats.

Quality & Process Reliability

Prioritize suppliers demonstrating documented quality control systems. While formal ISO 9001 certification is not universally listed, performance metrics such as on-time delivery rates above 95%, sub-3-hour response times, and reorder rates exceeding 30% indicate operational stability. In-process inspection protocols and first-article reporting are essential for traceability, especially in regulated industries.

Customization and Scalability

Assess customization depth beyond basic machining: look for providers offering surface finishing options (brushed, polished, bead-blasted), color coding, labeling, and packaging configurations. Evaluate scalability through factory size proxies (e.g., online revenue >US $10,000/month) and product breadth. Suppliers combining machining with sheet metal, molding, or additive manufacturing offer greater flexibility for hybrid prototypes.

What Are the Best Prototype Machining Services Suppliers?

| Company Name | Location | Main Products | On-Time Delivery | Reorder Rate | Avg. Response | Online Revenue | Min. Order | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Dongguan Yu Biao Hardware Co., Ltd. | Dongguan, CN | Machining Services, Sheet Metal, Fasteners | 95% | 30% | ≤3h | $290,000+ | 1 pc | Varies |

| Dongguan Jingrui Intelligent Manufacturing Co., Ltd. | Dongguan, CN | Machining Services, Plastic Crafts, Resin Parts | 85% | 33% | ≤2h | $4,000+ | 1 pc | $0.20–50 |

| Shenzhen GH Prototype Technology Co., Ltd. | Shenzhen, CN | Machining Services, Other Fabrication | 100% | 50% | ≤2h | $10,000+ | 1–2 pcs | $0.11–30 |

| JINKE VIETNAM INDUSTRIAL COMPANY LIMITED | Vietnam | Machining Services, Sheet Metal, Casting | 91% | - | ≤2h | $3,000+ | 100 pcs | $0.10–1.50 |

| JINKE VIET NAM INDUSTRIAL CO.,LTD | Vietnam | Machining Services, Sheet Metal, Moulds | 100% | - | ≤1h | $10,000+ | 1 pc | $0.10–3.20 |

Performance Analysis

Shenzhen GH Prototype Technology stands out with a 100% on-time delivery rate and 50% reorder rate, indicating strong customer retention and process reliability. Its competitive pricing and low minimum order requirements make it suitable for startups and R&D departments requiring frequent iterations. Dongguan Yu Biao Hardware demonstrates significant scale, backed by substantial online revenue and broad customization capabilities across fasteners, stamping, and engineered components.

Dongguan-based suppliers excel in responsiveness and diversified prototyping, including plastic and resin crafts ideal for consumer product mockups. The JINKE entities in Vietnam present a cost-efficient alternative, though one operates with higher MOQs (100 pieces), suggesting focus on early-stage batch production rather than one-off prototypes. Notably, JINKE VIET NAM INDUSTRIAL CO.,LTD combines sub-one-hour response times with full-service machining and mold-making, positioning it well for urgent redesign cycles.

FAQs

How to verify prototype machining supplier reliability?

Evaluate on-time delivery history, reorder rates, and response times as operational proxies. Request evidence of in-house machining capacity through facility videos or audit reports. Confirm material traceability and dimensional inspection practices, especially for precision-critical components.

What is the typical lead time for machined prototypes?

Standard CNC-machined prototypes take 5–9 business days from design approval. Complex geometries or those requiring post-processing (e.g., heat treatment, coating) may extend to 12–15 days. Rush services are available from select suppliers within 3–5 days at a premium.

Do suppliers support single-piece orders?

Yes, most suppliers in this segment accommodate MOQs of 1 piece, particularly for initial prototyping. However, unit costs decrease significantly at volumes above 10 units due to setup amortization.

Can I request custom finishes or branding on prototypes?

Yes, common customization options include anodizing, powder coating, silk screening, laser etching, and custom packaging. Suppliers often provide galvanized, threaded, or labeled variants upon request, enabling real-world usability testing.

How are prototype designs protected during production?

Buyers should establish NDAs and specify IP ownership terms prior to file submission. Reputable suppliers restrict access to design files and do not replicate parts for third parties without authorization. Some platforms offer encrypted data transfer and digital audit trails for added security.