Precision Prototype Machining

Top sponsor listing

Top sponsor listing

About precision prototype machining

Where to Find Precision Prototype Machining Suppliers?

China remains the global epicenter for precision prototype machining, with concentrated supplier clusters in Shenzhen, Dongguan, and Qingdao offering advanced manufacturing ecosystems. Shenzhen and Dongguan—key hubs within the Guangdong Province industrial belt—host over 70% of China’s high-precision CNC service providers, supported by mature supply chains for aluminum, stainless steel, and engineering plastics. These regions benefit from proximity to R&D centers and electronics OEMs, enabling rapid iteration cycles critical for prototyping.

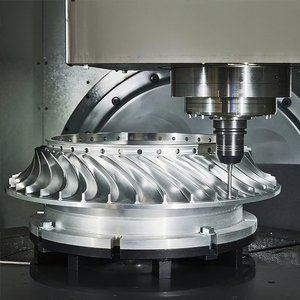

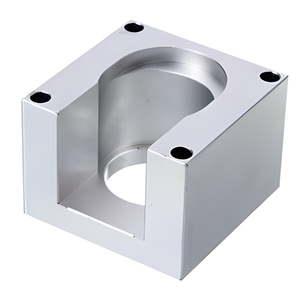

The clusters support vertical integration across design, tooling, machining, and surface treatment, reducing component lead times by 25–40% compared to non-specialized regions. Suppliers typically operate multi-axis CNC lathes, milling centers (3-, 4-, and 5-axis), grinding, and urethane casting systems, facilitating tight tolerances (±0.005mm) and complex geometries. Buyers gain access to agile production networks capable of fulfilling low-volume prototypes (1–100 units) with scalability to mid-volume runs, often within 5–15 days depending on complexity.

How to Choose Precision Prototype Machining Suppliers?

Evaluate suppliers using these critical criteria:

Technical Capability Verification

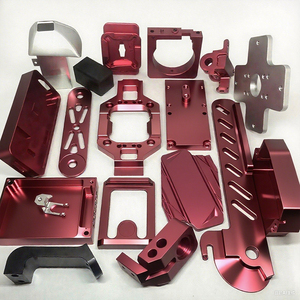

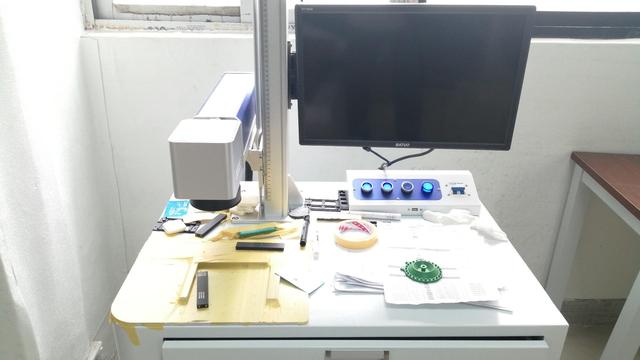

Confirm availability of multi-axis CNC systems (minimum 3-axis, preferred 5-axis) and in-house post-processing capabilities such as anodizing, plating, or laser engraving. For medical, aerospace, or automotive applications, ISO 9001 certification is essential; ISO 13485 or IATF 16949 compliance should be verified where applicable. Request dimensional inspection reports (CMM or optical measurement) for sample parts to validate process control.

Production Flexibility & Responsiveness

Assess responsiveness metrics and customization scope:

- Average response time ≤2 hours indicates operational efficiency

- On-time delivery rate ≥95% reflects reliable logistics and scheduling

- Customization options including material selection (aluminum, brass, PEEK, ABS), color, labeling, and packaging indicate process adaptability

- Reorder rate above 20% suggests customer satisfaction and consistent quality

Transaction Security & Quality Assurance

Prioritize suppliers with verifiable transaction histories and digital documentation. Utilize secure payment mechanisms that align with order milestones. Conduct virtual or on-site audits to verify facility size, machine count, and quality inspection protocols. Sample testing is critical—request first-article inspections before scaling production.

What Are the Best Precision Prototype Machining Suppliers?

| Company Name | Location | Main Products | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|---|

| Shenzhen Strongd Model Technology Co., Ltd. | Shenzhen, CN | Machining Services, Moulds, Casting, Aluminum Profiles | 98% | ≤2h | 41% | US $50,000+ | Color, material, size, logo, packaging, label, graphic |

| Shenzhen Flourish Legend Limited | Shenzhen, CN | Machining Services, Sheet Metal Fabrication, ABS Moulds | 100% | ≤1h | 16% | US $10,000+ | Not specified |

| Dongguan Kaizhida Precision Machinery Co., Ltd. | Dongguan, CN | Machining Services | 100% | ≤1h | - | - | Not specified |

| Shenzhen Yanmi Model Co., Ltd. | Shenzhen, CN | Machining Services, Moulds, Sheet Metal Fabrication | 100% | ≤2h | <15% | US $1,000+ | Not specified |

| 24K Investment (Qingdao) Co., Ltd. | Qingdao, CN | Machining Services, Sheet Metal, Moulds, Casting | 94% | ≤2h | 20% | US $10,000+ | Not specified |

Performance Analysis

Shenzhen-based suppliers dominate responsiveness and customization depth, with three of five achieving 100% on-time delivery. Shenzhen Strongd stands out with a 41% reorder rate—the highest among peers—indicating strong customer retention, likely driven by extensive customization and transparent communication. Dongguan Kaizhida and Shenzhen Flourish Legend offer rapid sub-one-hour responses, ideal for time-sensitive prototyping cycles. While Qingdao’s 24K Investment shows lower delivery reliability (94%), its diversified fabrication services provide flexibility for hybrid projects combining machining with sheet metal or casting. Buyers requiring full-service prototyping should prioritize suppliers with documented quality controls and multi-process capabilities.

FAQs

What materials are commonly used in precision prototype machining?

Aluminum alloys (6061, 7075), stainless steel (303, 316), brass, titanium, and engineering plastics (ABS, PEEK, Delrin) are standard. Material selection depends on mechanical, thermal, and corrosion resistance requirements.

What is the typical MOQ and lead time?

Minimum order quantities range from 1 to 100 pieces, with many suppliers offering single-unit prototyping. Lead times average 5–10 days for simple components and 10–15 days for complex, multi-process parts.

Can suppliers handle design-to-production workflows?

Yes, leading providers offer end-to-end services from CAD modeling and DFM analysis to functional prototyping and small-batch production. Confirm availability of reverse engineering or GD&T annotation support for technical drawings.

Are certifications available upon request?

While not all suppliers list certifications explicitly, reputable manufacturers can provide ISO 9001, material test reports (MTRs), and inspection documentation. Always request verification before large-scale orders.

How are quality issues resolved?

Established suppliers implement corrective action processes for non-conforming parts, including rework, replacement, or refund. Define acceptance criteria (AQL levels) and inspection methods during initial procurement discussions.