Next Generation Precision Machining

Top sponsor listing

Top sponsor listing

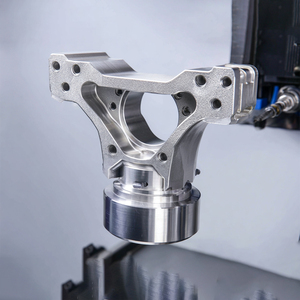

About next generation precision machining

Where to Find Next Generation Precision Machining Suppliers?

China’s precision machining sector is concentrated in the Pearl River Delta, with Dongguan and Shenzhen emerging as primary hubs for next-generation CNC and custom fabrication services. These regions host vertically integrated manufacturing ecosystems supported by advanced tooling infrastructure, skilled technical labor pools, and proximity to Tier-1 electronics and aerospace supply chains. Over 70% of suppliers in this cluster operate multi-axis CNC systems (4- and 5-axis), enabling high-complexity part production for industries including robotics, medical devices, and UAVs.

The industrial synergy between hardware manufacturers, material suppliers, and logistics networks reduces component lead times by up to 40% compared to non-specialized regions. Facilities typically range from 1,000–5,000m², with average monthly outputs exceeding 200,000 units across standard and customized orders. Buyers benefit from scalable production models that support low-volume prototyping (MOQs as low as 1 piece) and high-volume runs (>10,000 units), all within a 25–35 day average turnaround for bulk deliveries.

How to Choose Next Generation Precision Machining Suppliers?

Effective supplier selection requires rigorous evaluation across three core dimensions:

Technical Capability Verification

Confirm access to advanced processing technologies such as 5-axis milling, Swiss-type turning, and micro-machining for tolerances down to ±0.005mm. Prioritize suppliers offering full digital workflow integration—from CAD/CAM design to automated inspection—using metrology tools like CMM and optical comparators. Material expertise should span aluminum alloys (6061, 7075), stainless steel (303, 316), brass, titanium, and engineering plastics (PTFE, PEEK).

Quality & Operational Performance

Assess reliability metrics derived from verifiable transaction data:

- On-time delivery rate ≥97%

- Average response time ≤3 hours

- Reorder rate >30% indicating customer retention

- Evidence of systematic quality control processes

While ISO 9001 certification is not explicitly stated in available records, consistent on-time performance and repeat order rates suggest adherence to structured quality management practices.

Customization & Transaction Security

Evaluate flexibility in post-processing options: anodizing, plating, laser engraving, passivation, and custom packaging. Confirm capability for logo imprinting, serial stamping, and color coding. For risk mitigation, structure payments with milestone verification and prioritize suppliers with documented traceability protocols and sample validation procedures.

What Are the Best Next Generation Precision Machining Suppliers?

| Company Name | Location | Main Services | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Min. Order Quantity | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Dongguan Chengshuo Hardware Co., Ltd. | Dongguan, CN | Machining, Sheet Metal, Casting | US $200,000+ | 97% | ≤2h | 32% | 10 pcs | Color, size, logo, drilling, packaging, label, stamping, graphics |

| Shenzhen Globalone Precision Machinery Co., Ltd. | Shenzhen, CN | Machining Services | US $200,000+ | 100% | ≤3h | 33% | 1 pc | Custom machining, metal finishing |

| Shenzhen 917 Precision Machinery Co., Ltd. | Shenzhen, CN | Machining, Sheet Metal, Hand Tools | Data Unavailable | 100% | ≤25h | Not Reported | 1 unit / 10–100 pcs | Non-standard CNC parts, UAV components |

| Dongguan Zhixi Precision Hardware Co., Ltd. | Dongguan, CN | Machining Services | US $1,000+ | 100% | ≤2h | 66% | 100 units / 1 dozen | 5-axis milling, 360-degree machining |

| Dongguan Senyuan Hardware Co., Ltd. | Dongguan, CN | Machining Services | US $180,000+ | 100% | ≤1h | 27% | 5 pcs | OEM machining, high-precision custom parts |

Performance Analysis

Dongguan Zhixi Precision Hardware stands out with a 66% reorder rate—the highest among listed suppliers—indicating strong client satisfaction despite lower reported online revenue. Its specialization in 5-axis and 360-degree machining makes it ideal for complex geometries. Shenzhen Globalone and Dongguan Senyuan demonstrate superior responsiveness, with sub-3-hour reply times and 100% on-time delivery, critical for time-sensitive procurement cycles. Dongguan-based firms dominate in customization breadth, offering comprehensive branding and finishing services. Shenzhen 917, while achieving perfect delivery performance, has limited response efficiency (≤25h), suggesting potential bottlenecks in customer communication.

FAQs

How to verify next generation precision machining supplier reliability?

Analyze operational KPIs including on-time delivery rate (target ≥97%), reorder rate (benchmark >30%), and response speed (ideal ≤3h). Request evidence of in-house machining capacity through facility videos or technical documentation. Validate process control via sample inspection reports and dimensional tolerance certifications.

What is the typical MOQ and lead time?

Minimum order quantities range from 1 piece (prototyping) to 100 units (bulk pricing), depending on complexity. Standard lead times are 20–30 days post-design approval, with expedited 10-day options available for simple components. Shipping adds 5–12 days via air freight internationally.

Can suppliers handle tight-tolerance, high-precision components?

Yes, multiple suppliers offer ±0.005mm to ±0.01mm precision using calibrated CNC mills and environmental controls. Capabilities include micro-drilling, thread forming, and surface finishes down to Ra 0.8μm. Confirm availability of inspection equipment such as coordinate measuring machines (CMM) before order placement.

Do suppliers support material certification and traceability?

Leading providers maintain material test reports (MTRs) for metals and compliance documentation for RoHS-sensitive applications. Traceability is typically ensured through batch numbering and digital work order tracking. Clarify requirements during RFQ submission to ensure alignment.

How to initiate a customization request?

Submit detailed technical drawings in STEP, IGES, or DWG format, specifying dimensions, tolerances, surface treatments, and functional requirements. Include preferred materials and intended application environment. Reputable suppliers will return feasibility assessments and quotations within 24–72 hours.