Custom Precision Machining

Top sponsor listing

Top sponsor listing

1/11

1/11

1/19

1/19

1/11

1/11

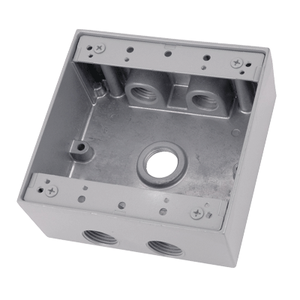

About custom precision machining

Where to Find Custom Precision Machining Suppliers?

China remains the global epicenter for custom precision machining services, with Shenzhen and Dongguan in Guangdong Province emerging as primary hubs due to their advanced manufacturing ecosystems. These regions host a dense network of CNC machining facilities specializing in tight-tolerance components for industries including medical devices, automation, aerospace, and consumer electronics. The concentration of tooling suppliers, material distributors, and post-processing specialists within 50km radii enables rapid prototyping and scalable production.

Suppliers in this cluster typically operate vertically integrated workshops equipped with multi-axis CNC lathes, milling centers, and EDM systems, supporting tolerances as tight as ±0.001mm. Localized supply chains reduce material lead times by 20–30% compared to offshore alternatives, while established logistics corridors facilitate air and sea freight to North America and Europe within 7–14 days. Buyers benefit from flexible batch sizing, with many providers accommodating prototype runs under 10 pieces alongside mass production exceeding 100,000 units monthly.

How to Choose Custom Precision Machining Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

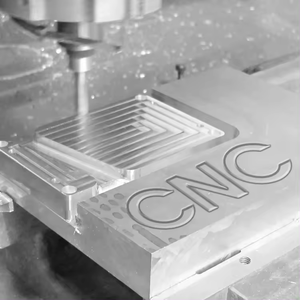

Technical Capabilities

Confirm access to 3-, 4-, and 5-axis CNC machining platforms for complex geometries. Evaluate support for secondary processes such as anodizing, sandblasting, PVD coating, heat treatment, and electroplating. Review CAD/CAM compatibility—reputable partners accept STEP, IGES, DWG, and PDF drawing formats and provide DFM feedback within 24 hours.

Quality Assurance Protocols

Prioritize suppliers with documented quality management systems. While formal ISO 9001 certification is not universally listed, consistent on-time delivery rates above 95% and reorder rates exceeding 50% indicate reliable process control. Request material certifications (e.g., mill test reports), first-article inspection reports, and SPC data for high-volume contracts.

Production & Responsiveness Metrics

Assess scalability through facility indicators where available. Key benchmarks include:

- Response time ≤3 hours for initial inquiry resolution

- On-time delivery performance ≥96%

- Reorder rate >50% as a proxy for customer satisfaction

- Minimum viable order size: 1 piece or 1 box (common MOQ structure)

Cross-reference these metrics with customization depth—such as color coding, logo stamping, packaging design, and assembly integration—to ensure alignment with project requirements.

What Are the Best Custom Precision Machining Suppliers?

| Company Name | Verified Type | Main Products | On-Time Delivery | Reorder Rate | Response Time | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|---|

| Shenzhen Runze Metal Technology Co., Ltd. | Custom Manufacturer | Sheet Metal Fabrication, Machining Services, Casting Services | 96% | 50% | ≤3h | US $1,800,000+ | Anodization, color, material, size, drawings, die casting, assembly, graphic, rubber coating |

| SkyReach Intelligent MFG Limited | Custom Manufacturer | Machining Services | 78% | <15% | ≤3h | US $30,000+ | Color, material, size, logo, packaging, label, graphic |

| Shenzhen Chuangyi Precision Hardware Co., Ltd. | Not Specified | Machining Services, Sheet Metal Fabrication, Moulds | 100% | <15% | ≤1h | US $20,000+ | Limited customization data |

| Shenzhen Qunhengli Technology Co., Ltd. | Not Specified | Machining Services, Casting Services, Moulds | 100% | 50% | ≤2h | US $6,000+ | Broad product integration capabilities |

| Reko Technology Co., Limited | Multispecialty Supplier | CNC Machining, Medical Parts, Hardware | 100% | 66% | ≤3h | US $30,000+ | Precision turning, EDM, plating, polishing, deburring, material testing, thermo treatment |

Performance Analysis

Shenzhen Runze Metal and Reko Technology stand out with 50%+ reorder rates and comprehensive customization, indicating strong client retention and technical versatility. Reko Technology achieves the highest reorder rate (66%) despite average response time, suggesting superior post-delivery performance. Shenzhen Chuangyi excels in responsiveness (≤1h) and perfect on-time delivery, making it suitable for urgent turnaround needs. SkyReach, while offering standard CNC services, shows lower repeat business (<15%), which may reflect limited differentiation or service consistency. Suppliers with online revenues exceeding US $1 million demonstrate proven export experience and volume-handling capacity.

FAQs

How to verify custom precision machining supplier reliability?

Validate performance claims through verifiable metrics: on-time delivery rate, reorder frequency, and response speed. Request evidence of process controls, such as inspection checklists, gauge repeatability studies, and material traceability reports. For critical applications, conduct remote factory audits via live video tours to assess machinery condition and workflow organization.

What is the typical lead time for prototypes and production orders?

Standard prototype lead time ranges from 5 to 10 days after drawing approval. Production batches (1,000–10,000 pcs) typically ship within 20–30 days. Express services may reduce timelines by 30–50% at premium cost. Complex parts requiring secondary operations (e.g., heat treatment or plating) add 3–7 days.

Can suppliers handle full turnkey manufacturing?

Yes, select suppliers offer end-to-end solutions including raw material sourcing, CNC machining, surface finishing, sub-assembly, packaging, and drop shipping. Reko Technology and Shenzhen Runze explicitly support integrated workflows with labeling, branding, and kitting options.

Do machining suppliers provide free samples?

Sample policies vary. Some suppliers waive fees for future bulk commitments, while others charge partial cost recovery (typically 30–70% of unit price). Free samples are more likely when annual projected volumes exceed 5,000 units.

How to initiate a customization request?

Submit detailed technical specifications including material type (e.g., aluminum 6061-T6, stainless steel 316L), dimensional tolerances, surface finish requirements (Ra value), and any required certifications. Include 2D/3D drawings with annotations. Leading suppliers respond with DFM analysis and quotation within 24–48 hours.