Rapid Prototype Machining

Top sponsor listing

Top sponsor listing

About rapid prototype machining

Where to Find Rapid Prototype Machining Suppliers?

China remains the global hub for rapid prototype machining, with leading suppliers concentrated in the Pearl River Delta region—particularly Shenzhen and Dongguan. These manufacturing clusters offer integrated ecosystems combining precision CNC workshops, material sourcing networks, and logistics infrastructure, enabling fast turnaround times and cost-efficient production. The proximity of component suppliers, tooling specialists, and surface treatment facilities within a 50km radius reduces coordination delays and supports agile prototyping cycles.

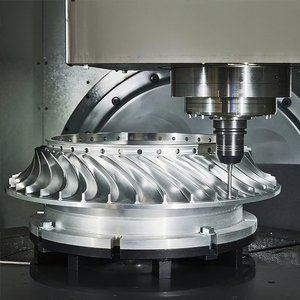

Suppliers in this region specialize in low-volume, high-mix production models ideal for functional prototypes and pre-series validation. Many operate vertically integrated facilities equipped with 3-, 4-, and 5-axis CNC machines, Swiss-type lathes, and EDM systems, allowing complex geometries in metals and engineering plastics. Buyers benefit from average lead times of 7–14 days for machined prototypes, with some providers offering expedited 3-day services for urgent requests. Localized supply chains contribute to 20–30% lower unit costs compared to equivalent Western-based vendors, particularly for aluminum, stainless steel, brass, and PEEK materials.

How to Choose Rapid Prototype Machining Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

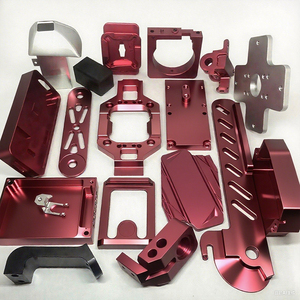

Confirm access to multi-axis CNC machining (minimum 3-axis, preferably 5-axis) and secondary processing such as anodizing, sandblasting, electroplating, or PVD coating. Review CAD/CAM compatibility—reputable suppliers support STEP, IGES, and 2D DWG formats. For medical or aerospace applications, verify compliance with ISO 13485 or AS9100 standards. CE, RoHS, or REACH declarations are essential for EU market-bound components.

Production Infrastructure Assessment

Evaluate key capacity indicators:

- Facility size supporting dedicated R&D and QC zones

- In-house tooling and mold-making capabilities for iterative design adjustments

- Material certification reporting and traceability protocols

Cross-reference equipment lists with on-time delivery performance (target ≥93%) and reorder rates (ideally >40%) to assess reliability and customer satisfaction.

Procurement Risk Mitigation

Utilize secure payment mechanisms that align financial release with milestone verification. Prioritize suppliers with documented quality control processes, including first-article inspection reports (FAIR), coordinate measuring machine (CMM) data, and material test certificates. Request physical or digital samples before scaling to larger batches to validate dimensional accuracy and surface finish consistency.

What Are the Best Rapid Prototype Machining Suppliers?

| Company Name | Verified Type | Main Products | Online Revenue | On-Time Delivery | Response Time | Reorder Rate | Customization Options | Min. Order Quantity |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Strongd Model Technology Co., Ltd. | Custom Manufacturer | Machining Services, Moulds, Casting, Aluminum Profiles | US $50,000+ | 98% | ≤2h | 41% | Color, material, size, logo, packaging, graphic | 1 piece |

| Dongguan Thriving Metal Parts Co., Ltd. | Custom Manufacturer | CNC Turning, Swiss-Type Machining, Mold Making | US $470,000+ | 93% | ≤2h | 37% | Material, finish, drawing, lead time, weight, labeling | 1–3 pieces |

| SkyReach Intelligent MFG Limited | Custom Manufacturer | Precision CNC Machining, Large-Scale Fabrication | US $20,000+ | 76% | ≤3h | 15% | Color, size, logo, packaging | 1 piece |

| Reko Technology Co., Limited | Multispecialty Supplier | Precision Metal Parts, EDM, Medical Components | US $30,000+ | 100% | ≤3h | 66% | Anodizing, plating, heat treatment, deburring, drawing | 1 piece |

| Dongguan Jingrui Intelligent Manufacturing Co., Ltd. | Not Specified | Machining Services, 3D Printing, Sheet Metal | US $4,000+ | 85% | ≤2h | 33% | Color, material, size, finish, lead time | 1 piece |

Performance Analysis

Reko Technology stands out with a perfect 100% on-time delivery rate and the highest reorder rate (66%), indicating strong process discipline and customer retention, likely driven by advanced finishing options like PVD plating and medical-grade polishing. Dongguan Thriving leads in online transaction volume (US $470,000+), reflecting robust export activity and broad client trust. Shenzhen Strongd combines high responsiveness (≤2h) with consistent delivery (98%) and moderate reorder frequency, suggesting stable service execution. SkyReach, despite lower on-time performance (76%), offers competitive pricing and scalability for large-format prototypes. Dongguan Jingrui integrates additive manufacturing with traditional machining, providing hybrid solutions for complex assemblies but operates at a smaller scale.

FAQs

How to verify rapid prototype machining supplier reliability?

Request evidence of quality management systems (e.g., ISO 9001), facility audits, and sample inspection reports. Validate technical claims through video tours of CNC floors and QC labs. Analyze historical order data focusing on delivery consistency and post-sale communication efficiency.

What is the typical lead time for machined prototypes?

Standard lead times range from 7 to 14 days after design approval. Expedited services can deliver parts in 3–5 days, depending on complexity and material availability. Additive-assisted hybrid processes may reduce timelines further for non-metallic components.

Do suppliers support small-batch customization?

Yes, most suppliers listed accept MOQs as low as 1 piece, catering to R&D and startup prototyping needs. Customization includes geometry, surface finish, color coding, branding, and packaging configurations.

What materials are commonly used in rapid prototype machining?

Aluminum 6061/7075, stainless steel 303/316, brass C3604, titanium, PEEK, Delrin, and nylon are widely available. Material selection depends on mechanical, thermal, and regulatory requirements, with full traceability documentation provided upon request.

Can suppliers handle full project lifecycle support?

Top-tier providers offer end-to-end services—from initial design review and DFM feedback to functional testing and pilot-run scaling. Reko Technology and Dongguan Thriving explicitly list engineering support for turning, milling, and assembly integration, making them suitable for complex product development cycles.