Rapid Prototype Machining Corporation

Top sponsor listing

Top sponsor listing

1/21

1/21

1/18

1/18

1/17

1/17

CN

CN

1/13

1/13

About rapid prototype machining corporation

Where to Find Rapid Prototype Machining Suppliers?

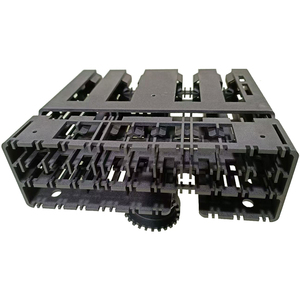

China remains the global hub for rapid prototype machining services, with key manufacturing clusters in Shenzhen, Dongguan, and Guangzhou offering specialized expertise in high-precision prototyping. These regions host vertically integrated facilities that combine CNC machining, 3D printing (SLA, SLS), sheet metal fabrication, and injection molding under one roof, enabling end-to-end prototype development. Shenzhen and Dongguan benefit from proximity to semiconductor and consumer electronics supply chains, supporting fast-turnaround projects for tech-driven industries.

The concentration of technical talent and component suppliers within these industrial zones reduces lead times by up to 40% compared to decentralized production models. Suppliers typically operate multi-axis CNC centers (3–5 axis), resin-based 3D printing systems, and precision milling equipment, allowing them to handle complex geometries in metals (aluminum, titanium, stainless steel) and engineering plastics (ABS, PC, nylon, PP). Average monthly output capacity among mid-tier providers ranges from 10,000 to 50,000 units, scalable based on project complexity and material requirements.

How to Choose Rapid Prototype Machining Suppliers?

Procurement decisions should be guided by a structured evaluation framework focusing on technical capability, quality assurance, and transaction reliability:

Technical & Production Capabilities

Verify access to advanced processing technologies including:

- CNC turning and milling (supporting tolerances down to ±0.005mm)

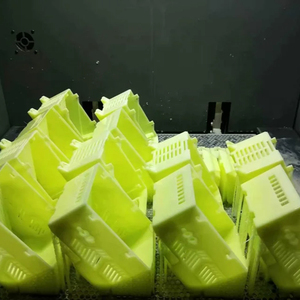

- Multi-material 3D printing (SLA, SLS, FDM) for functional prototypes

- In-house tooling and mold-making capabilities for low-volume production

- Surface finishing options: anodizing, plating, painting, sandblasting

Assess customization depth—leading suppliers support full OEM/ODM workflows, including design optimization, material selection, DFM analysis, and post-processing. Confirm compatibility with requested materials and dimensional specifications through sample validation.

Quality Management Systems

While formal ISO 9001 certification is not universally listed, operational metrics indicate robust internal controls. Prioritize suppliers demonstrating:

- On-time delivery rates ≥97%

- Reorder rates exceeding 50%, indicating customer retention

- Response times under 3 hours for technical inquiries

Request evidence of in-process inspection protocols, first-article testing reports, and final QA documentation. For regulated sectors (medical, aerospace), confirm compliance with RoHS, REACH, or industry-specific standards.

Transaction & Risk Mitigation

Leverage digital platforms to validate supplier credibility through verifiable performance data. Key indicators include online transaction volume (e.g., annual revenue >US $30,000), repeat order frequency, and responsiveness. Use secure payment mechanisms such as escrow services until prototype approval. Always request physical or digital samples before scaling to mass production to verify dimensional accuracy, surface finish, and material properties.

What Are the Best Rapid Prototype Machining Suppliers?

| Company Name | Main Products | Online Revenue | On-Time Delivery | Reorder Rate | Avg. Response | Customization Options | Key Services |

|---|---|---|---|---|---|---|---|

| Shenzhen Zhongyi Hardware Products Co., Ltd. | Machining Services | US $1,000+ | 100% | <15% | ≤2h | N/A | CNC Machining, Metal Fabrication |

| Dongguan Jingrui Intelligent Manufacturing Co., Ltd. | Machining Services, Plastic Crafts, Sheet Metal | US $1,000+ | 83% | 33% | ≤1h | Color, material, size, logo, packaging | SLA 3D Printing, Precision Machining |

| Guangzhou Gaojie Model Design & Manufacturing Co., Ltd. | Machining Services, Moulds | US $30,000+ | 100% | 85% | ≤5h | N/A | Rapid Prototyping, ABS/PC/Nylon Machining |

| SkyReach Intelligent MFG Limited | Customization-focused machining | US $30,000+ | 87% | 15% | ≤3h | Color, size, logo, 3D drawings, packaging | 3–5 Axis CNC, Titanium/Plastic Components |

| Huzhou Dear Industry Co., Ltd. | OEM Machining, Resin Prototypes | US $360,000+ | 100% | 50% | ≤6h | Material (TPU, EPDM), hardness, transparency, labeling | Injection Molding, Custom CNC Milling |

Performance Analysis

Huzhou Dear Industry stands out with the highest recorded online revenue (US $360,000+) and a 50% reorder rate, suggesting strong client satisfaction and consistent quality delivery. Guangzhou Gaojie demonstrates exceptional reliability with 100% on-time fulfillment and a high 85% reorder rate, indicative of successful long-term partnerships. SkyReach and Dongguan Jingrui offer extensive customization breadth, particularly in plastic resins and aesthetic finishes, making them suitable for consumer product developers. Shenzhen Zhongyi and Huzhou Dear maintain perfect delivery records, critical for time-sensitive R&D cycles. Buyers requiring tight tolerances and metal prototyping should prioritize suppliers with documented CNC infrastructure and material traceability.

FAQs

What is the typical MOQ for rapid prototype machining?

Most suppliers offer a minimum order quantity of 1 piece, especially for initial prototypes. Some resin-based or injection molding services may require 100 pieces or more depending on setup costs.

How long does prototype production take?

Standard lead times range from 3 to 7 days for CNC-machined parts and 5 to 10 days for 3D-printed models. Complex designs or additional finishing processes may extend timelines by 2–4 days.

Do suppliers provide design for manufacturability (DFM) feedback?

Yes, leading providers offer free DFM analysis to optimize part geometry, reduce costs, and prevent production issues. Submit STEP, IGES, or STL files for review.

Can I customize materials and surface finishes?

Affirmative. Most suppliers support a wide range of thermoplastics (ABS, PC, POM, nylon) and metals (aluminum 6061/7075, stainless steel, brass). Surface treatments include bead blasting, anodizing (Type II/III), powder coating, and laser engraving.

Are samples available before bulk production?

Yes, functional prototypes are routinely produced for validation. Sample pricing varies by complexity but often ranges from $0.15 to $50 per unit, sometimes credited toward larger orders.